Nutrient-rich assistant lipid-lowering health food and preparation method thereof

An auxiliary blood lipid-lowering and nutrient-rich technology, applied in the field of health food, can solve problems such as inability to meet functions and nutrition, and achieve obvious effects, maintain lipid metabolism balance, and maintain body health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

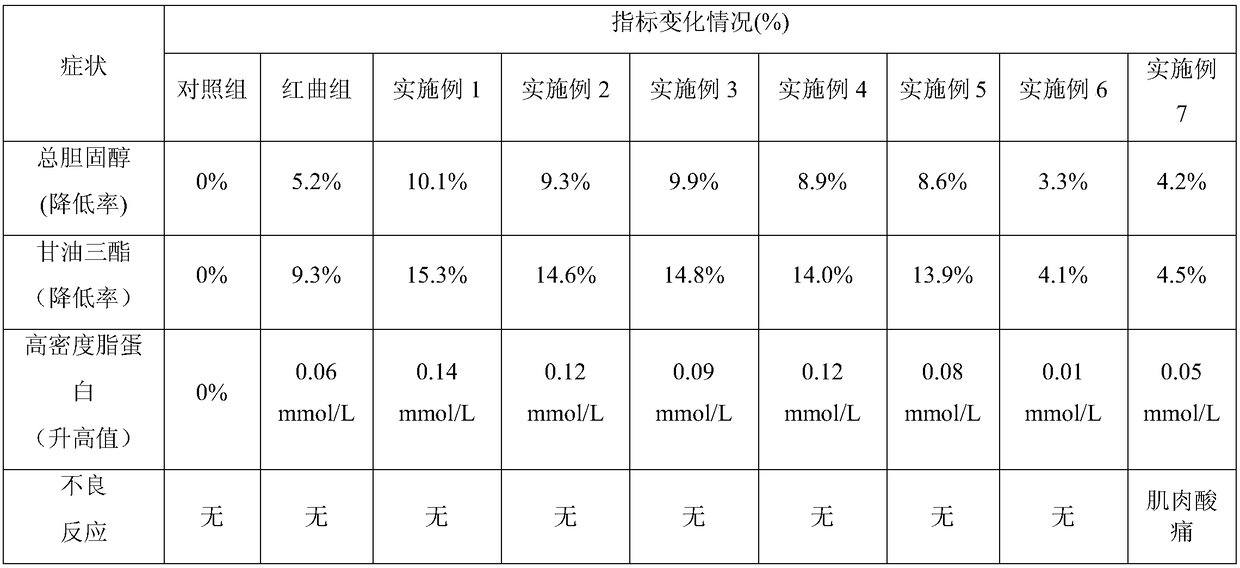

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of a nutrient-rich auxiliary blood fat-lowering health food, comprising the following steps:

[0044] Step 1. Sieve the functional red yeast rice powder, microcrystalline cellulose, pregelatinized starch, silicon dioxide and magnesium stearate to 80 mesh respectively, and sieve the natto powder to 60 mesh, and set aside;

[0045] Step 2, weighing each component after sieving in step 1 according to the above parts by weight;

[0046] Step 3. Mix functional red yeast rice powder, microcrystalline cellulose, and pregelatinized starch to obtain mixed powder, add water to make soft material, granulate through a sieve to obtain wet granules, dry and granulate to obtain uniform-sized granules ;

[0047] Step 4. After the natto powder is uniformly mixed with the granules prepared in Step 2, silicon dioxide and magnesium stearate are added and mixed to prepare a nutritious auxiliary blood fat-lowering health food.

Embodiment 1

[0050] Step 1. Sieve the functional red yeast rice powder, microcrystalline cellulose, pregelatinized starch, silicon dioxide and magnesium stearate to 80 mesh respectively, and sieve the natto powder to 60 mesh, and set aside;

[0051] Step 2. Weigh the components after sieving in step 1: 20g of functional red yeast rice powder, 30g of microcrystalline cellulose, 50g of natto powder, 20g of pregelatinized starch, 5g of silicon dioxide, and 5g of magnesium stearate ;

[0052] Step 3. Mix functional red yeast rice powder, microcrystalline cellulose, and pregelatinized starch to obtain mixed powder, add water to make soft material, granulate through a sieve to obtain wet granules, dry and granulate to obtain uniform-sized granules ;

[0053] Step 4. After the natto powder is mixed evenly with the granules obtained in step 2, silicon dioxide and magnesium stearate are added and mixed to obtain a mixed powder, which is filled into capsules and made into 0.3 g / granule.

Embodiment 2

[0055] Step 1. Sieve the functional red yeast rice powder, microcrystalline cellulose, pregelatinized starch, silicon dioxide and magnesium stearate to 80 mesh respectively, and sieve the natto powder to 60 mesh, and set aside;

[0056] Step 2. Weigh the sieved raw materials in step 1: 30g of functional red yeast rice powder, 30g of microcrystalline cellulose, 40g of natto powder, 10g of pregelatinized starch, 2g of silicon dioxide, and 2g of magnesium stearate;

[0057] Step 3. Mix functional red yeast rice powder, microcrystalline cellulose, and pregelatinized starch to obtain mixed powder, add water to make soft material, granulate through a sieve to obtain wet granules, dry and granulate to obtain uniform-sized granules ;

[0058] Step 4. After the natto powder is mixed evenly with the granules obtained in step 2, silicon dioxide and magnesium stearate are added and mixed to obtain a mixed powder, which is filled into capsules and made into 0.3 g / granule.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com