A kind of preparation method and application of surfactant-modified metal oxide catalyst

A technology of surfactants and oxides, which is applied in the field of preparation of surfactant-modified metal oxide catalysts, can solve the problems of high processing cost, frequent regeneration, harsh reaction conditions and other problems of breakpoint chlorination, and achieve excellent catalytic ozone Oxidative removal of ammonia nitrogen, low production cost, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

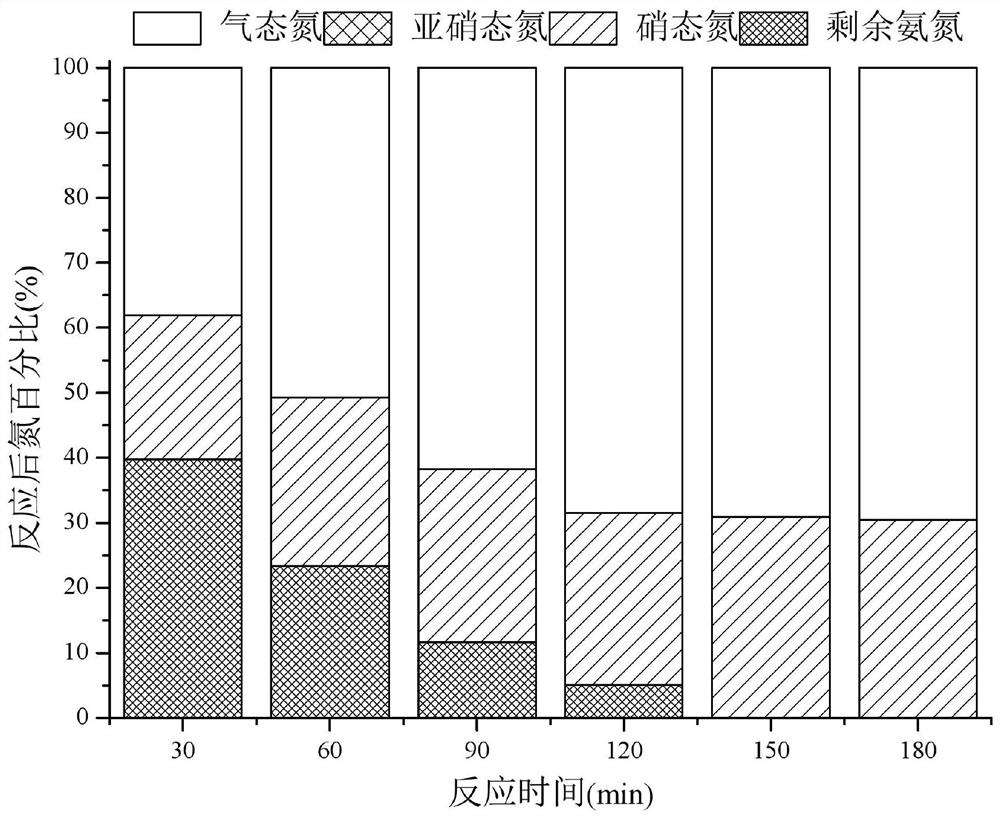

Image

Examples

Embodiment 1

[0020] The preparation of surfactant-modified metal oxide catalyst (CTAB / NiO), the specific steps are: NiCl 2 •6H 2 O, NaOH, and cetyltrimethylammonium bromide were ground in an agate mortar evenly, and then pressed by NiCl 2 •6H 2 The molar ratio of O: NaOH: hexadecyltrimethylammonium bromide is 1: 2.1: 0.093. Mix the three solid substances evenly, and grind the mixture for 60 minutes, so that the three solid substances are fully mixed evenly, and then in Dry the mixture in the oven at a controlled temperature of 90°C and cool it to room temperature, then grind the mixture into powder, place the powder in a muffle furnace at a temperature of 300°C for 120 minutes and then cool to room temperature, that is A CTAB / NiO catalyst modified with a surfactant was obtained.

[0021] For comparison, the ground NiCl 2 • 6H 2 O and NaOH were mixed uniformly at a molar ratio of 1: 2.1, and then mixed and ground for 60 minutes, so that the two were fully mixed, and then the mixture...

Embodiment 2

[0024] The preparation of surfactant-modified metal oxide catalyst (SDS / ZnO), the specific steps are: ZnCl 2 , NaOH, and sodium lauryl sulfate were ground in an agate mortar evenly, and then pressed by ZnCl 2 : NaOH: The molar ratio of sodium lauryl sulfate is 1: 2.1: 0.155. Mix the three solid substances evenly, and grind the mixture for 60 minutes to fully mix the three solid substances, and then control the temperature in the oven. Dry the mixture at 90°C and cool it to room temperature, then grind the mixture into powder, place the powder in a muffle furnace at 400°C for 180 minutes and then cool it down to room temperature to obtain surfactant-modified SDS / ZnO catalysts of metal oxides.

[0025] For comparison, the ground ZnCl 2 Mix well with NaOH at a molar ratio of 1: 2.1, and then mix and grind for 60 minutes to make the two fully mix evenly, then dry the mixture in an oven at a temperature of 90°C and cool it to room temperature, after that, the mixture Grinding th...

Embodiment 3

[0028] The preparation of surfactant-modified metal oxide catalyst (SLS / NiO), the specific steps are: NiCl 2 • 6H 2 O, NaOH, and sodium lauroyl sarcosinate were ground in an agate mortar evenly, and then pressed by NiCl 2 • 6H 2 The molar ratio of O: NaOH: sodium lauroyl sarcosinate is 1:2.1:0.217. Mix the three solid substances evenly, and grind the mixture for 60 minutes, so that the three solid substances are fully mixed evenly, and then control the temperature in the oven Dry the mixture at 90°C and cool it to room temperature, then grind the mixture into powder, place the powder in a muffle furnace at 250°C for 180 minutes and then cool it to room temperature to obtain the surfactant Modified metal oxide SLS / NiO catalysts.

[0029] For comparison, the ground NiCl 2 • 6H 2 O and NaOH were mixed uniformly at a molar ratio of 1: 2.1, and then mixed and ground for 60 minutes, so that the two were fully mixed, and then the mixture was dried and cooled to room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com