Two-dimensional adjustable SnSSe porous nanosheet as well as preparation and application thereof

A nanosheet, hydrothermal reaction technology, applied in nanotechnology, chemical instruments and methods, photometry using electrical radiation detectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Provided is a method for preparing a two-dimensional tunable SnSSe porous nanosheet, which specifically includes the following steps:

[0024] Step (1). SnCl 4 、Na 2 SeO 3 , thiourea, oleic acid amide, hydrazine hydrate, sodium cetylbenzenesulfonate and water according to the mass ratio 2: (1 ~ 3): (1 ~ 3): (1 ~ 3): (4 ~ 6): (4~6): 50 mixed, placed in a hydrothermal reaction kettle for hydrothermal reaction;

[0025] Preferably, the hydrothermal reaction temperature is 180-200°C, and the constant temperature time is 18-24 hours;

[0026] Step (2). The solid-liquid mixture after the hydrothermal reaction is subjected to solid-liquid centrifugation, the liquid product is poured out, the solid product is taken out, washed alternately with deionized water and alcohol for 3 times, and then dried at 70-80°C for 4 ~6 hours;

[0027] As preferably, the number of times of washing is 3 times;

[0028] Preferably, the drying temperature is 70-80°C, and the drying time is 4-6...

Embodiment 1

[0032] 2gSnCl 4 , 2gNa 2 SeO 3 , 2g thiourea, 2g oleic acid amide, 5g hydrazine hydrate, 5g sodium cetylbenzenesulfonate and 50g water are mixed according to the mass ratio of 2:2:2:2:5:5:50, and placed in a hydrothermal reaction kettle The hydrothermal reaction is carried out in the medium, the hydrothermal reaction temperature is 180 ° C, and the constant temperature time is 18 hours; the solid-liquid mixture after the hydrothermal reaction is subjected to solid-liquid centrifugation, the liquid product is poured out, the solid product is taken out, and deionized water, Alternative washing with alcohol for 3 times and drying at 70°C for 4 hours; the dried product was ground into powder to obtain two-dimensional tunable SnSSe porous nanosheets.

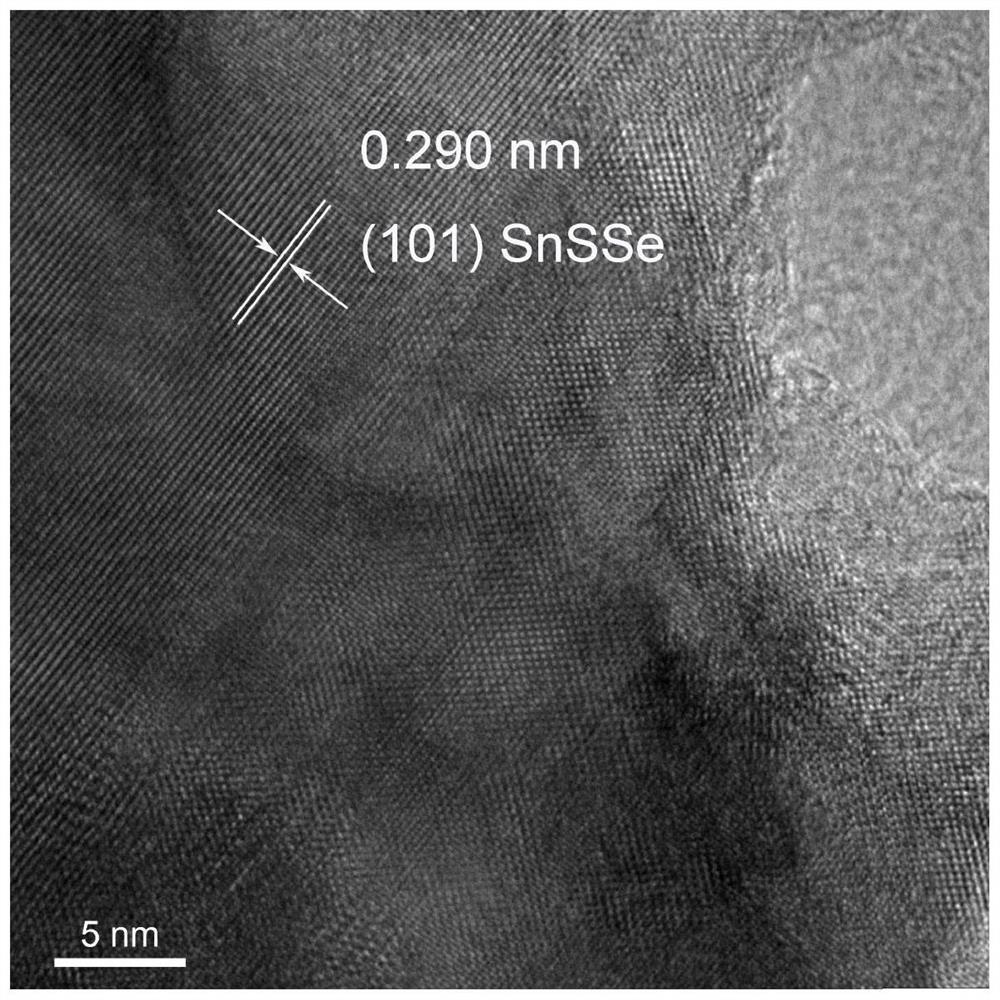

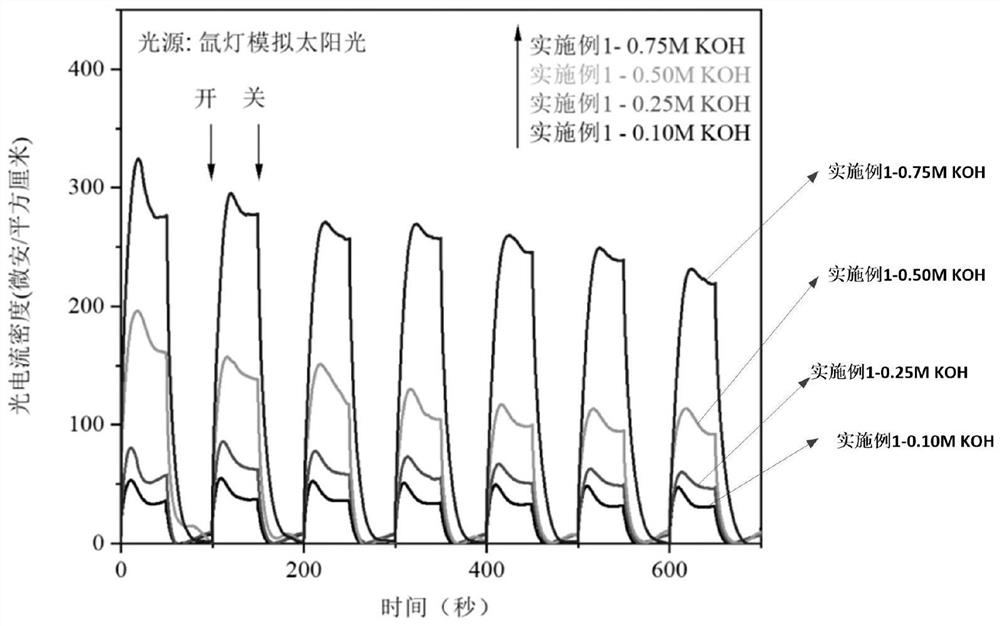

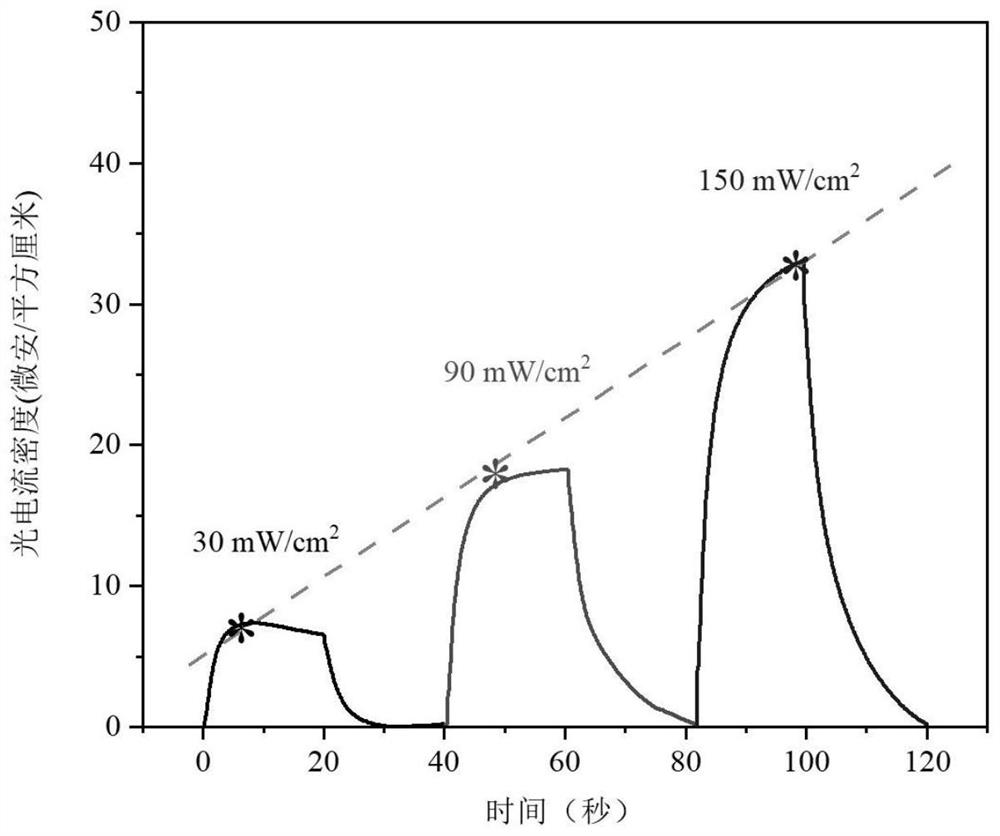

[0033] figure 1 The transmission electron microscope figure (TEM) of the two-dimensional tunable SnSSe porous nanosheet prepared for embodiment 1; As can be seen, the SnSSe prepared in embodiment 1 presents a porous nanosheet stru...

Embodiment 2

[0037] 2gSnCl 4 , 1gNa 2 SeO 3 , 1g of thiourea, 1g of oleic acid amide, 4g of hydrazine hydrate, 4g of sodium cetylbenzenesulfonate and 50g of water are mixed according to the mass ratio of 2:1:1:1:4:4:50, and placed in a hydrothermal reaction kettle The hydrothermal reaction is carried out in the medium, the hydrothermal reaction temperature is 200 ° C, and the constant temperature time is 20 hours; the solid-liquid mixture after the hydrothermal reaction is subjected to solid-liquid centrifugation, the liquid product is poured out, the solid product is taken out, and deionized water, Alternative washing with alcohol for 3 times and drying at 80°C for 5 hours; the dried product was ground into powder to obtain two-dimensional tunable SnSSe porous nanosheets.

[0038] Figure 4 For the X-ray diffraction spectrum (XRD) of the two-dimensional adjustable SnSSe porous nanosheet prepared in Example 2; as can be seen from it, the diffraction peak of the two-dimensional adjustable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com