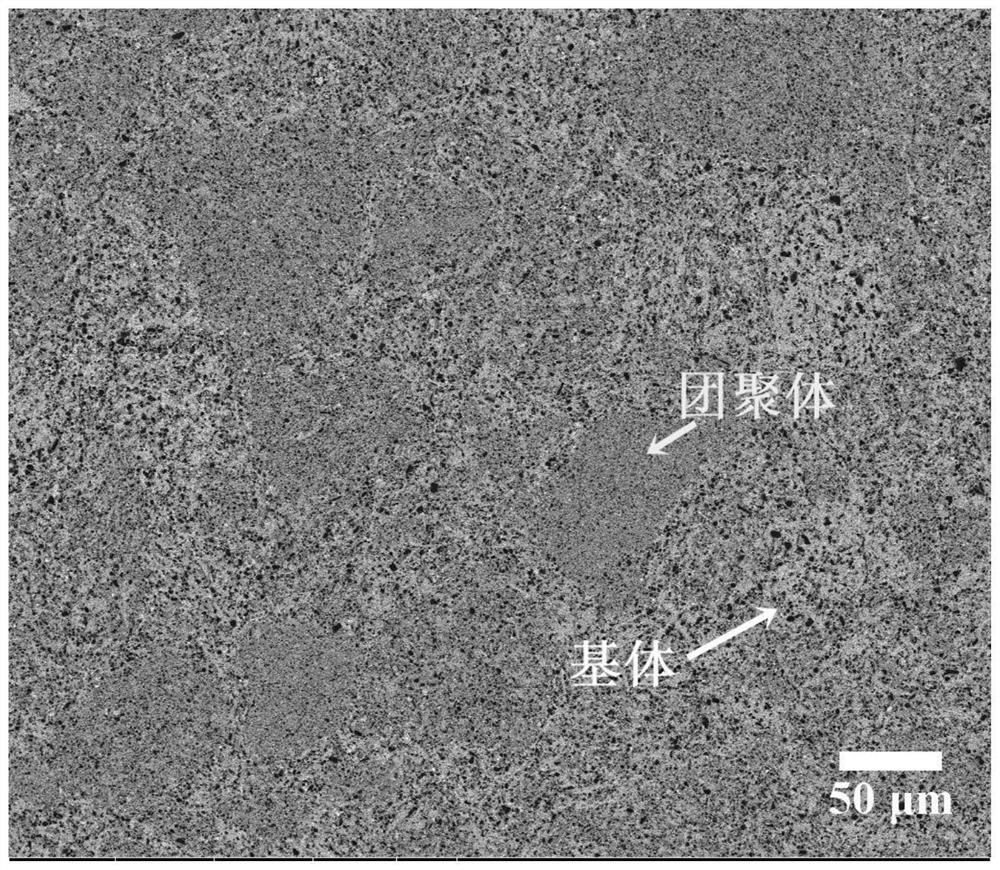

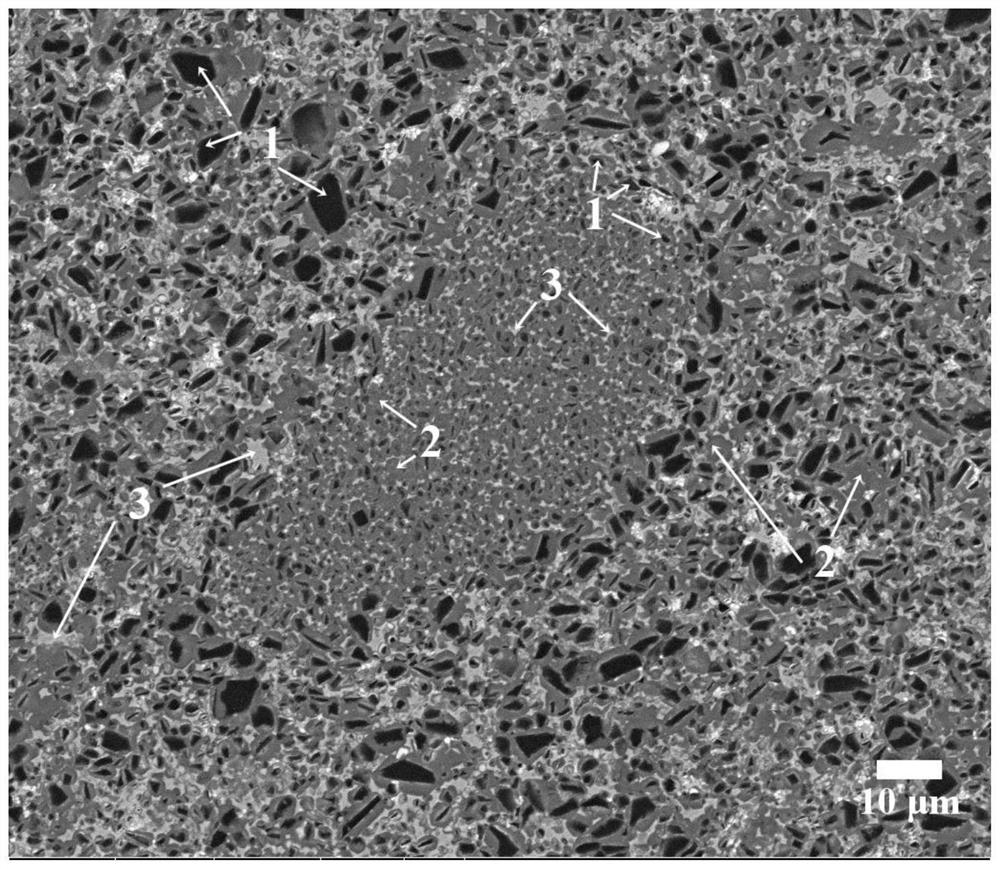

Ti (C, N)-based metal ceramic with honeycomb structure and preparation method of Ti (C, N)-based metal ceramic

A cermet, honeycomb technology, applied in the field of powder metallurgy, can solve the problems of low fracture toughness and low comprehensive mechanical properties, and achieves the effect of simple process, simple process and convenient industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Preparation of mixture 1: with TiO 2 Powder, TiN powder and graphite powder are used as raw materials, and 4 kinds of mixed powders 1 are prepared according to Table 1, placed in a planetary ball mill for ball milling, and anhydrous ethanol is added as a ball milling medium, and the amount added is 1.2 times the weight of the mixture 1. It is 6:1, the ball mill speed is 250rpm, and the ball milling time is 18h;

[0039] 2. Preparation of mixture 2: Add coarse particles of Ti(C,N), Ni, Mo to the mixed slurry 1 obtained in step 1 2 C, WC, Cr 3 C 2 , AlN and graphite powder, prepare 4 kinds of mixtures 2 according to Table 2, and continue to place them in a planetary ball mill for ball milling, and add anhydrous ethanol as a ball milling medium, and the addition amount is 1.4 times the weight difference between mixture 2 and mixture 1 , the ball-to-material ratio is 7:1, the ball mill speed is 180rpm, and the ball milling time is 14h;

Embodiment 2

[0050] The preparation steps of the cermet of the present embodiment are as follows:

[0051] 1. Preparation of mixture 1: with TiO 2 Powder, TiN powder and graphite powder are used as raw materials, and 4 kinds of mixed powders 1 are prepared according to Table 1, placed in a planetary ball mill for ball milling, and anhydrous ethanol is added as a ball milling medium, and the amount added is 1.3 times the weight of the mixture 1. It is 6:1, the ball mill speed is 200rpm, and the ball milling time is 28h;

[0052] 2. Preparation of mixture 2: Add coarse particles of Ti(C,N), Ni, Mo to the mixed slurry 1 obtained in step 1 2 C, WC, Cr 3 C 2 , AlN and graphite powder, prepare 4 kinds of mixtures 2 according to Table 2, and continue to place them in a planetary ball mill for ball milling, and add anhydrous ethanol as a ball milling medium, and the amount added is 1.3 times the weight difference between mixture 2 and mixture 1 , the ball-to-material ratio is 7:1, the ball mil...

Embodiment 3

[0062] The preparation steps of the cermet of the present embodiment are as follows:

[0063] 1. Preparation of mixture 1: with TiO 2 Powder, TiN powder and graphite powder are used as raw materials, and 4 kinds of mixed powders 1 are prepared according to Table 1, placed in a planetary ball mill for ball milling, and anhydrous ethanol is added as a ball milling medium, and the amount added is 1.4 times the weight of the mixture 1. It is 6:1, the ball mill speed is 300rpm, and the ball milling time is 24h;

[0064] 2. Preparation of mixture 2: Add coarse particles of Ti(C,N), Ni, Mo to the mixed slurry 1 obtained in step 1 2 C, WC, Cr 3 C 2 , AlN and graphite powder, prepare 4 kinds of mixtures 2 according to Table 2, and continue to place them in a planetary ball mill for ball milling, and add anhydrous ethanol as a ball milling medium, and the addition amount is 1.2 times the weight difference between mixture 2 and mixture 1 , the ball-to-material ratio is 7:1, the ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com