A method and device for measuring microstructure topography based on dispersion spectrum coding

A shape measurement and microstructure technology, applied in measuring devices, optical devices, instruments, etc., can solve problems such as weak anti-interference ability, achieve high-precision measurement, improve controllability and anti-interference ability, and suppress measurement effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

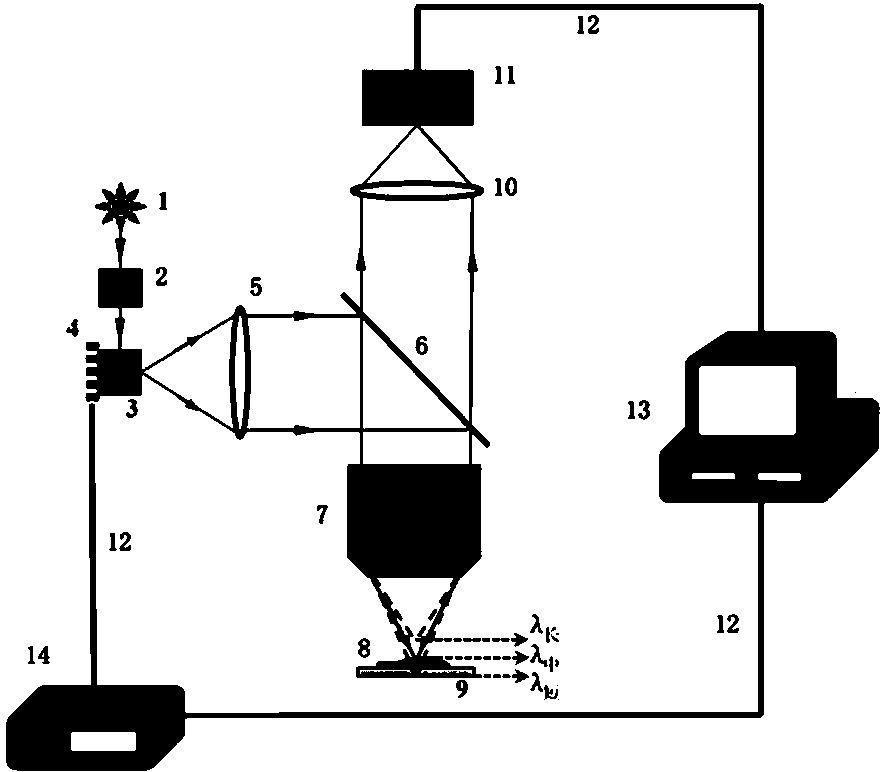

[0029] See attached figure 1 , which is a structural schematic diagram of the microstructure topography measurement device based on dispersion spectrum coding provided in this embodiment. The measuring device consists of a wide-spectrum light source 1, a beam homogeneous coupler 2, a beam deflection coupler 3, a spatial light modulator 4, a collimator beam expander lens 5, a beam splitter 6, an axial dispersion microscopic objective lens 7, An object stage 8, an imaging coupling lens 10, a snapshot multi / hyperspectral imaging detector 11, a data transmission control line 12, a computer 13 and a controller 14 are composed. The computer 13 is respectively connected to the controller 14 and the snapshot multi / hyperspectral imaging detector 11 via the data transmission control line 12; the measured element 8 is placed on the stage 9, and the measured element 8 and the spatial light modulator 4 are measuring The object-image conjugate is present at the central wavelength of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com