Pungent and spicy beef jerky and production method thereof

A production method, the technology of beef jerky, is applied in the direction of using chemicals to preserve meat/fish, food ingredients as antioxidants, food science, etc. It can solve the problems of high time cost, difficulty in chewing, and many preparation procedures for beef jerky, and achieve Helps digestion and absorption, prolongs storage time, and increases practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1: Material preparation

[0041] 1) To choose fresh beef, the beef is required to be yellow beef, and the muscle of the beef is uniformly red and shiny, and the fat is white or milky yellow.

[0042] 2) Prepare raw materials according to the following mass parts: 480g fresh beef, 35g white sugar, 8g edible salt, 10g rice wine, 30g edible vegetable oil, 70g pepper, 40g pepper, 3g pepper, 1.2g sodium glutamate, 1.2g red yeast rice , glycerin 10g.

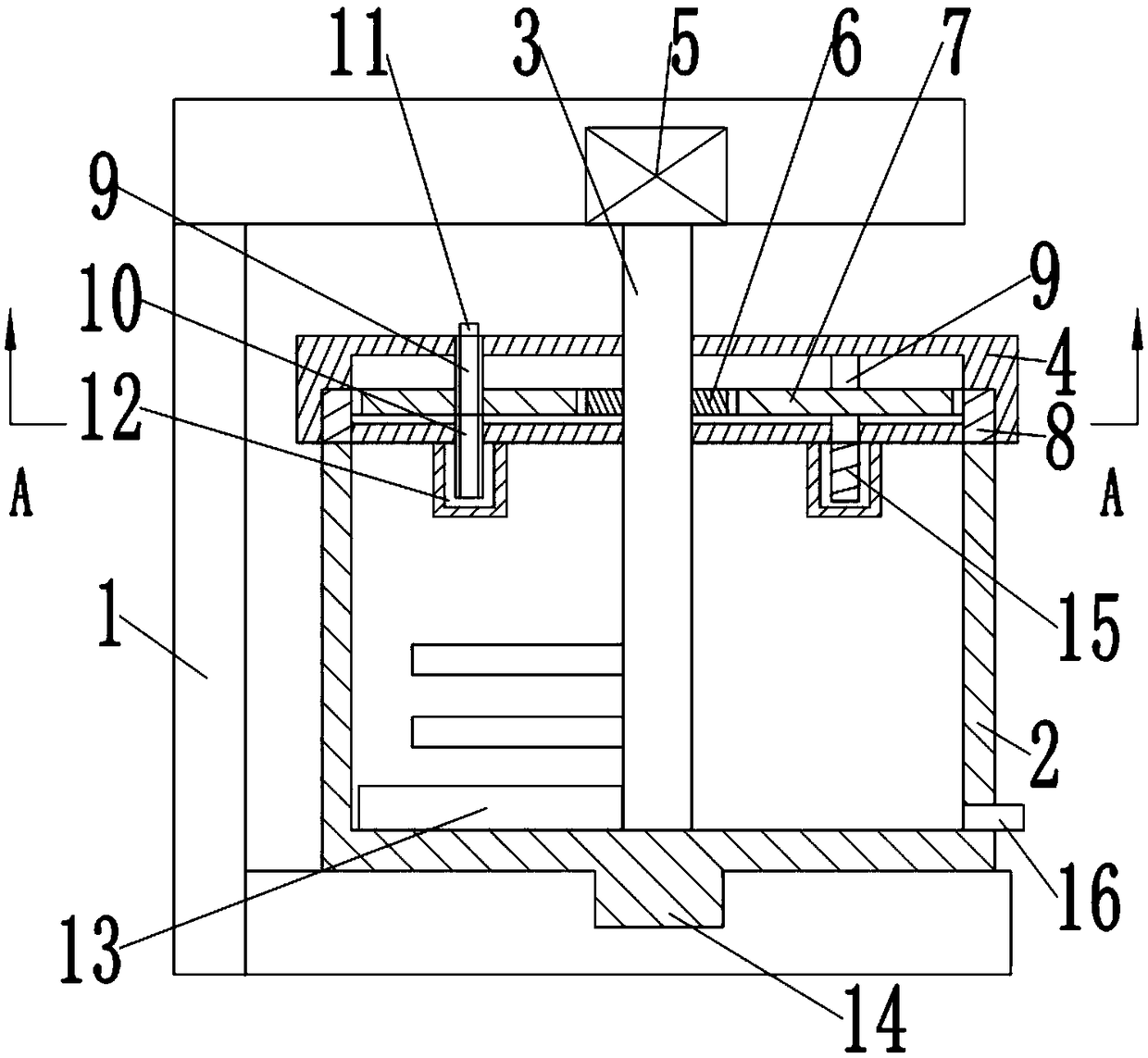

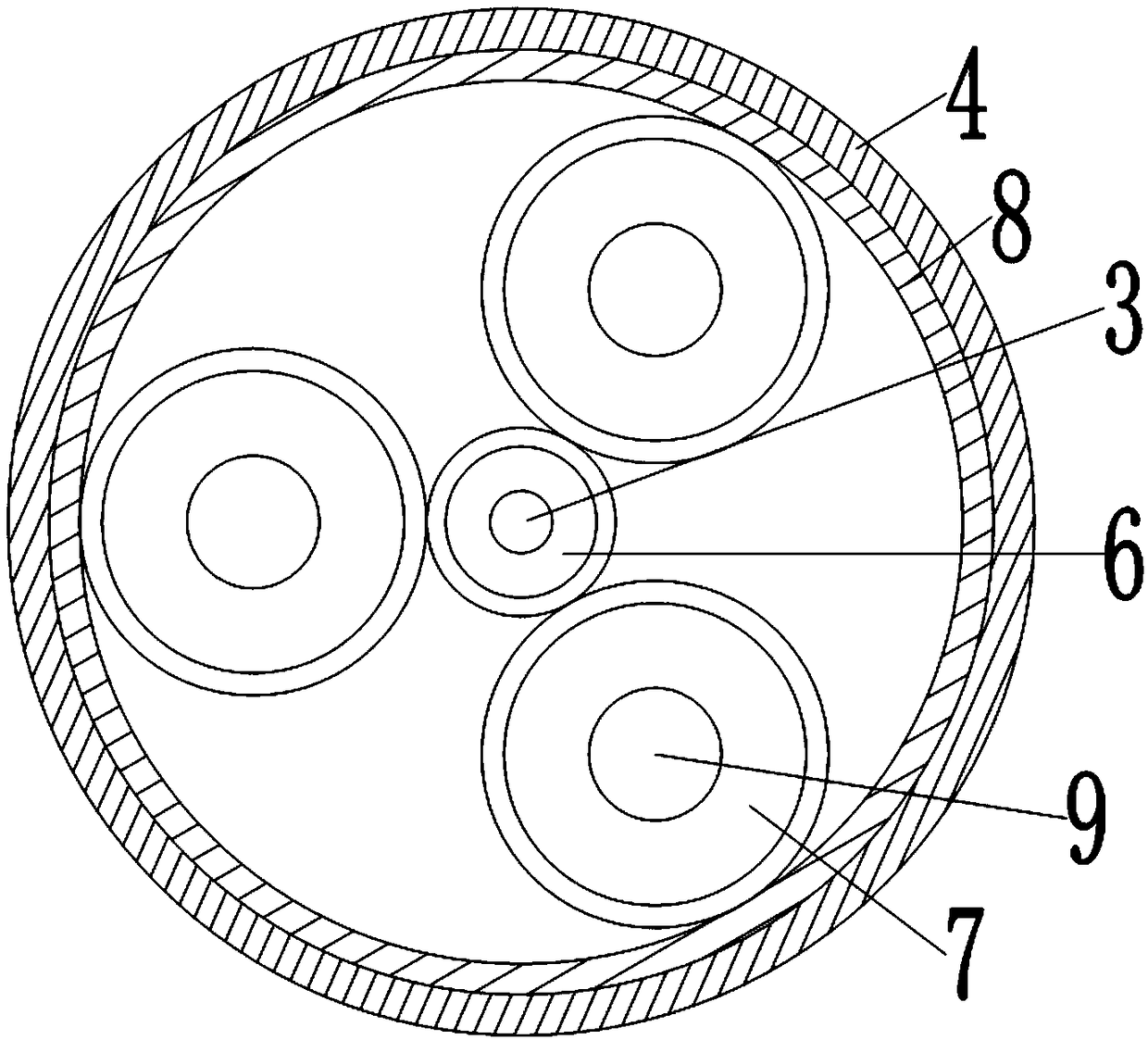

[0043] 3) Prepare the stir-frying device, the stir-frying device is basically as figure 1 As shown, it includes a frame 1, a frying tube 2 and a power shaft 3. The frying tube 2 is rotatably connected to the frame 1. The specific settings are as follows. The frame 1 is integrally formed with a cylindrical groove, and the bottom of the frying tube 2 is A column 14 for cooperating with the cylindrical groove is fixedly connected to the outer surface of the outer surface, and the stir-frying drum 2 and the frame 1 realize t...

Embodiment 2

[0057] The difference between this embodiment and Example 1 is that the raw materials and mass parts of spicy beef jerky are as follows: 510g of fresh beef, 40g of white sugar, 12g of edible salt, 12g of rice wine, 35g of edible vegetable oil, 80g of pepper, 50g of Chinese prickly ash, pepper 5g, sodium glutamate 2.0g, monascus red 1.8g, glycerin 15g.

Embodiment 3

[0059] The difference between this embodiment and Embodiment 1 is that the raw materials and mass parts of spicy beef jerky are as follows: 495g of fresh beef, 38g of white sugar, 10g of edible salt, 11g of rice wine, 33g of edible vegetable oil, 75g of pepper, 45g of Chinese prickly ash, pepper 4g, Sodium Glutamate 1.6g, Monascus Red 1.5g, Glycerin 13g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com