Oxyhemoglobin saturation monitor based on wireless transmission technology

A wireless transmission and saturation technology, applied in the field of medical devices, can solve the problems of inaccurate monitoring of blood oxygen saturation data, reduce hospital procurement costs, etc., achieve accurate data detection, fast analog-to-digital conversion, and solve inaccurate data monitoring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The following is attached Figure 1-9 The present invention will be better explained in detail.

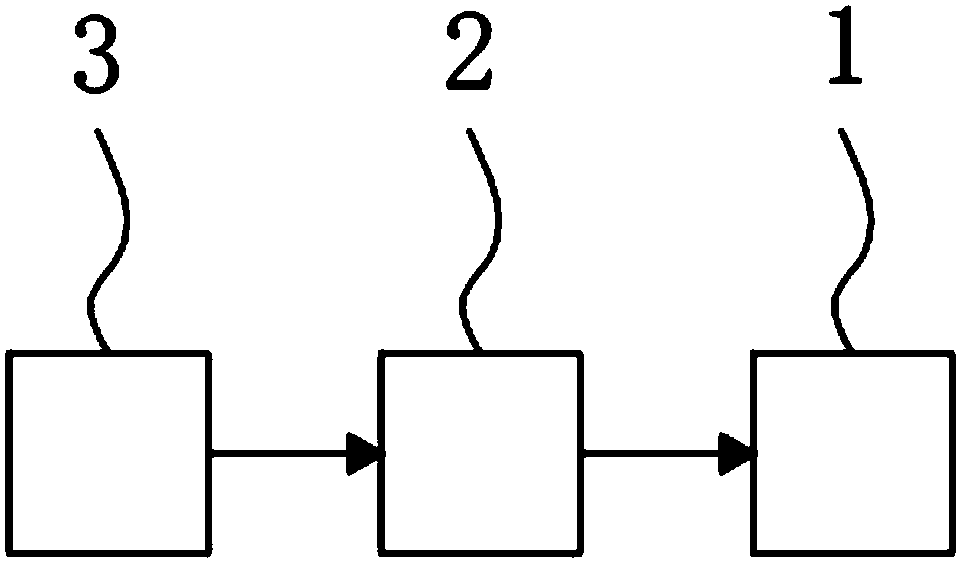

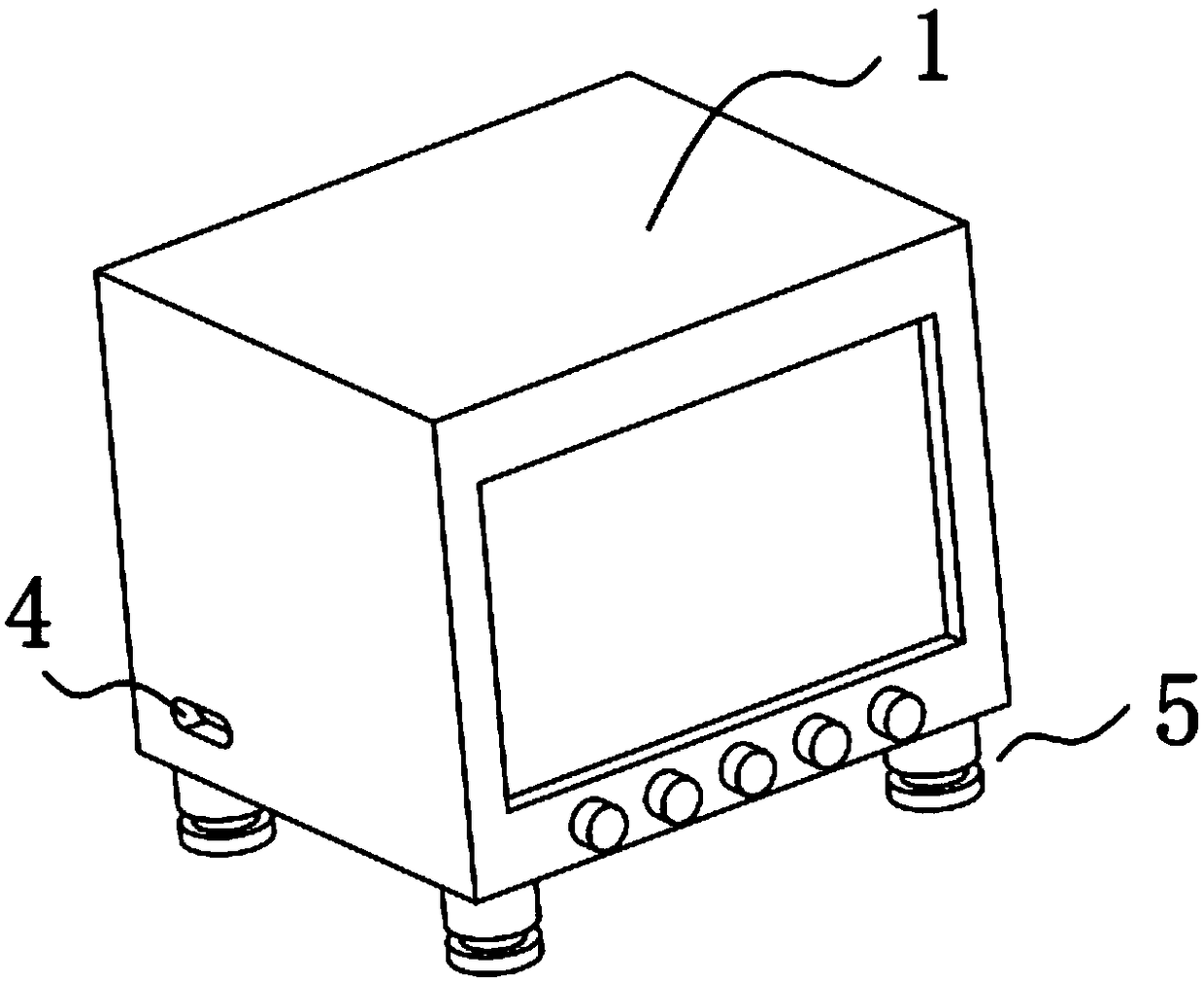

[0053] A blood oxygen saturation monitor based on wireless transmission technology, such as Figure 1-9 As shown, it includes a blood oxygen saturation monitor body 1, a wireless receiving device 2 and a wireless sending device 3. The wireless sending device 3 is connected to the wireless receiving device 2 via a wireless signal, and the wireless receiving device 2 is connected to the wireless receiving device 2 via a data cable. The blood oxygen saturation monitor body 1 is connected;

[0054] The bottom of the blood oxygen saturation monitor body 1 is symmetrically provided with four shock-absorbing feet 5, and an outer side wall of the blood oxygen saturation monitor body 1 is embedded with a first USB data interface 4 electrically connected to its internal main board ;

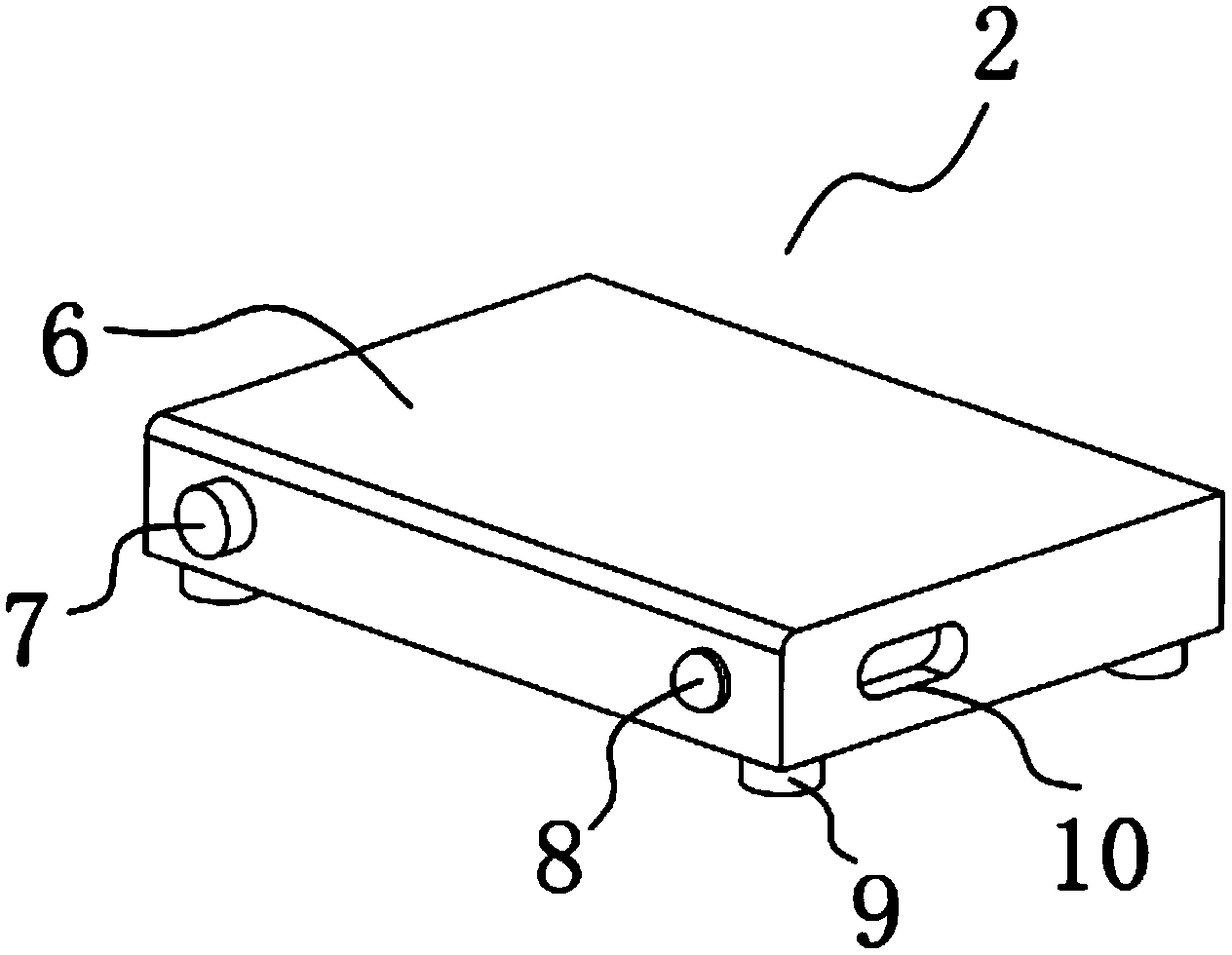

[0055] The wireless receiving device 2 includes a box body 6, a Bluetooth receiver 12 is fixedly install...

Embodiment 2

[0066] The difference from Embodiment 1 is that the inner surfaces of the first arc-shaped groove 17 and the second arc-shaped groove 18 are both provided with a non-slip coating, and the non-slip coating is prepared by the following method:

[0067] Weigh the following raw materials in parts by weight: 40 parts epoxy resin, 20 parts quartz powder, 60 parts ethanol, 5 parts calcium carbonate powder, 5 parts titanium dioxide powder, 6 parts zinc phosphate powder, 2 parts antioxidant, 3 parts accelerator And 3 parts of softener;

[0068] S1. Add the weighed epoxy resin, quartz powder, calcium carbonate powder, titanium dioxide powder and zinc phosphate powder into a ball mill for fine grinding to a particle diameter of 20um to obtain a mixed powder material;

[0069] S2. The mixed powder material and ethanol prepared in step S1 are added to the mixer for stirring for 15 minutes, and the stirring speed of the mixer is set to 600r / min;

[0070] S3. After the mixer in step S2 stops working...

Embodiment 3

[0075] The difference from Example 2 is the preparation of the non-slip coating. The specific preparation method is as follows:

[0076] Weigh the following raw materials in parts by weight: 50 parts of epoxy resin, 25 parts of quartz powder, 70 parts of ethanol, 8 parts of calcium carbonate powder, 7 parts of titanium dioxide powder, 8 parts of zinc phosphate powder, 3 parts of antioxidants, 4 parts of accelerators And 4 parts of softener;

[0077] S1. Add the weighed epoxy resin, quartz powder, calcium carbonate powder, titanium dioxide powder and zinc phosphate powder into a ball mill for fine grinding to a particle diameter of 30um to obtain a mixed powder material;

[0078] S2. The mixed powder material and ethanol prepared in step S1 are added to the mixer for stirring for 20 minutes, and the stirring speed of the mixer is set to 700 r / min;

[0079] S3. After the mixer in step S2 stops working, add antioxidants, accelerators and softeners to the mixer, reset the stirring time to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com