High efficiency biological engineering tail gas treatment equipment, processing method thereof, and fermentation tank

A bioengineering and tail gas treatment technology, which is applied in separation methods, chemical instruments and methods, and air quality improvement, can solve problems such as strong tail gas odor, environmental pollution, and poor tail gas treatment effects, and achieve enhanced activity and stability, improved Treatment efficiency, complete and thorough treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0038] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

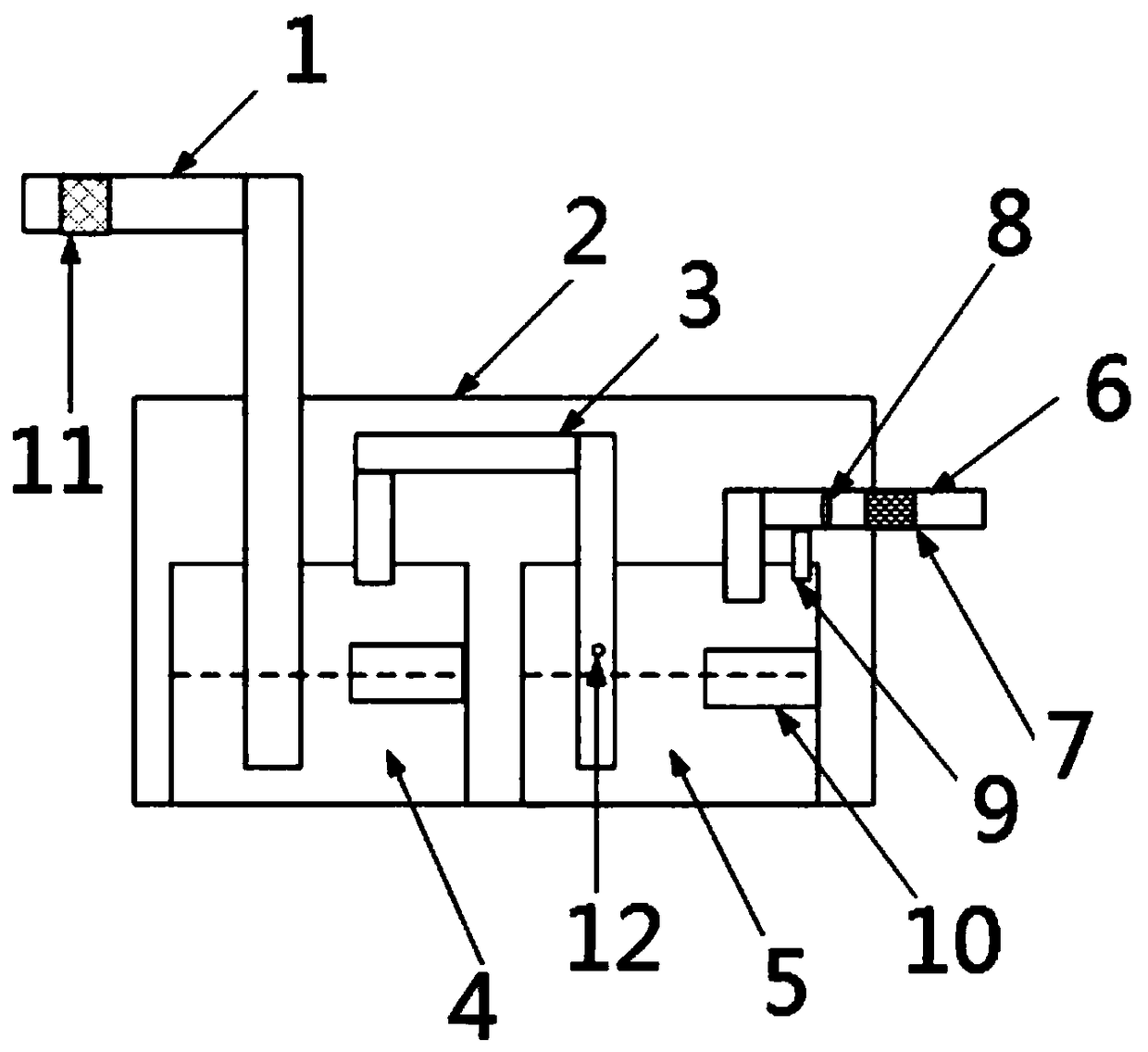

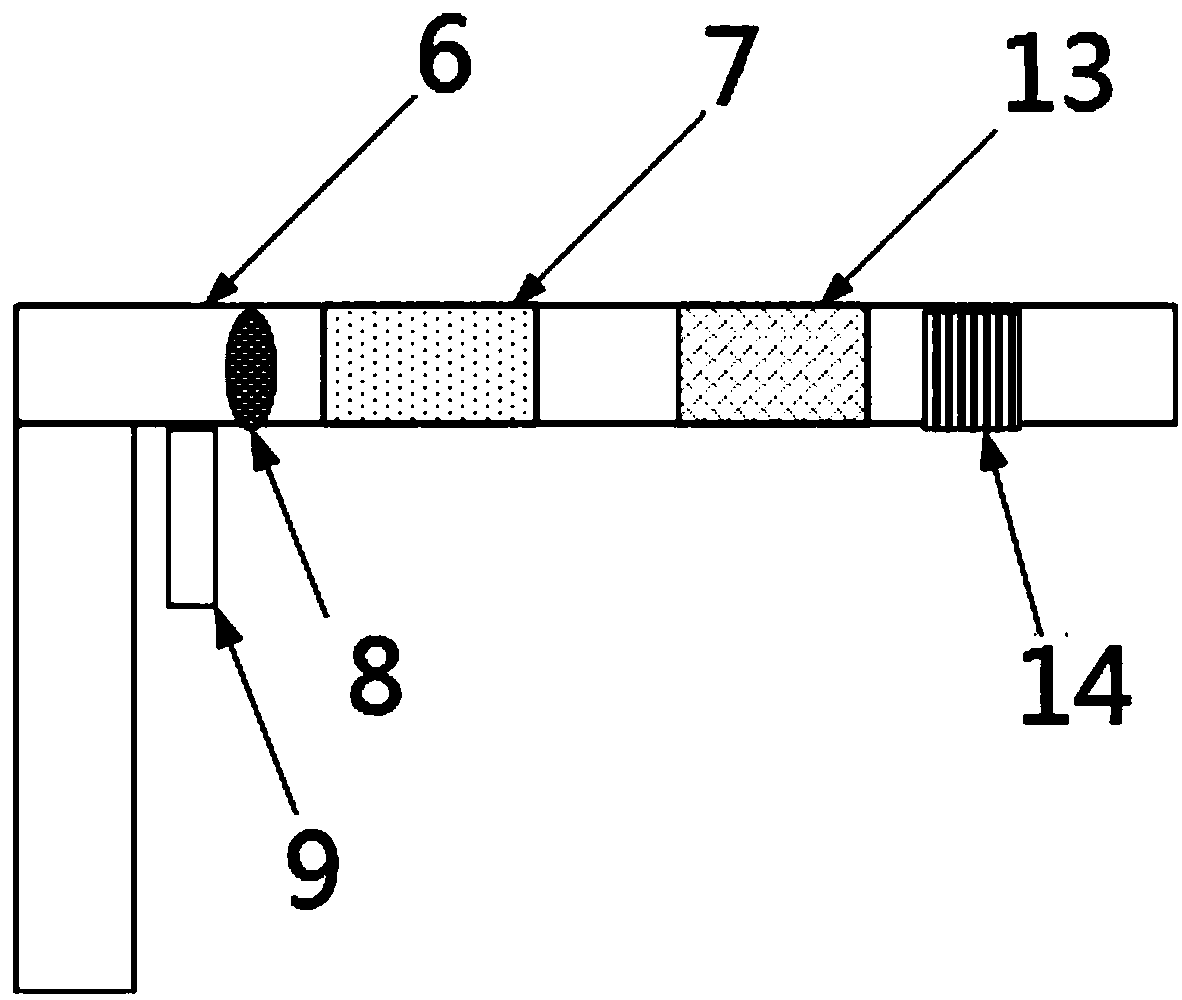

[0039] Such as figure 1 and figure 2 As shown, the high-efficiency bioengineering tail gas treatment equipment described in the embodiment of the present invention includes: inlet pipe 1, reaction chamber 2, conduit 3, primary bioreactor 4, secondary bioreactor 5, outlet pipe 6, activated carbon adsorption Block 13, three-way catalyst 14, replaceable card slot 7, cell filter 8, condensation return pipe 9, liquid level monitoring window 10, gas filter 11, anti-suckback hole 12.

[0040] The inlet pipe 1 is inserted into the reaction chamber 2, the primary bioreactor 4 is fixed to the reaction chamber 2 by screws, and the secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com