Preparation method of uniform and stable type liquid crystal microcapsule material

A stable, microcapsule technology, used in liquid crystal materials, microcapsule preparations, microsphere preparation, etc., can solve the problems of poor storage stability, poor size uniformity, etc., to reduce uneven dispersion performance, improve stability performance, The effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

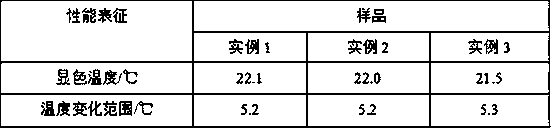

Examples

example 1

[0017] Take the pig brain and wash it, remove the fat and fascia, freeze-dry it in vacuum, grind it and pass it through a 200-mesh sieve to get the sieved powder, add the sieved powder to acetone at a mass ratio of 1:10, stir and mix Heated in a water bath at 45°C for 1 hour and allowed to cool to room temperature, filtered and collected the filtrate, then crystallized in a water bath at 0°C, collected the crystals and washed 3 times with 90% ethanol solution, and dried naturally to obtain the modified cholesteryl ester ; Then in parts by weight, weigh 45 parts of xylene, 10 parts of p-benzenemethanesulfonic acid, 6 parts of polyglycerol and 10 parts of modified cholesteryl ester in a beaker, stir and mix and heat at 55°C Reflux treatment for 1 hour, let it cool down to room temperature and collect the mixed solution. According to the volume ratio of 1:1, stir the mixed solution with acetone and place it at 0°C for crystallization in a water bath again. Collect the crystals and...

example 2

[0019] Take the pig brain and wash it, remove the fat and fascia, freeze-dry it in vacuum, grind it and pass it through a 200-mesh sieve to get the sieved powder, add the sieved powder to acetone at a mass ratio of 1:10, stir and mix Heated in a water bath at 47°C for 2 hours and allowed to cool to room temperature, filtered and collected the filtrate, then crystallized in a water bath at 2°C, collected the crystals and washed 4 times with 90% ethanol solution, and dried naturally to obtain the modified cholesteryl ester ; Then weigh 47 parts of xylene, 12 parts of p-benzenemethanesulfonic acid, 7 parts of polyglycerol and 12 parts of modified cholesteryl ester in a beaker, stir and mix and heat at 57°C Reflux for 2 hours, let stand to cool to room temperature and collect the mixed solution. According to the volume ratio of 1:1, stir the mixed solution with acetone and place it at 2°C for crystallization in a water bath again. Collect the crystals and vacuum freeze-dry to obtai...

example 3

[0021] Take the pig brain and wash it, remove the fat and fascia, freeze-dry it in vacuum, grind it and pass it through a 200-mesh sieve to get the sieved powder, add the sieved powder to acetone at a mass ratio of 1:10, stir and mix Heated in a water bath at 50°C for 2 hours and allowed to cool to room temperature, filtered and collected the filtrate, then crystallized in a water bath at 5°C, collected the crystals and washed 5 times with a 90% ethanol solution, and dried naturally to obtain the modified cholesteryl ester ; Then weigh 50 parts of xylene, 15 parts of p-benzenemethanesulfonic acid, 8 parts of polyglycerol and 10-15 parts of modified cholesteryl ester in a beaker, stir and mix and place at 60°C Heating under reflux for 2 hours, standing to cool to room temperature and collecting the mixed solution, according to the volume ratio of 1:1, stirring the mixed solution with acetone and placing it at 5°C for crystallization in a water bath again, collecting the crystals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com