MEMS SOI wafer and preparation method, and MEMS sensor and preparation method

A manufacturing method and wafer technology, applied in the field of MEMS sensors, can solve the problems of film thickness deviation, unusable wafers, MEMS membrane structure rupture, etc., to avoid film rupture and fragmentation, improve local stress concentration, and overcome film thickness deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

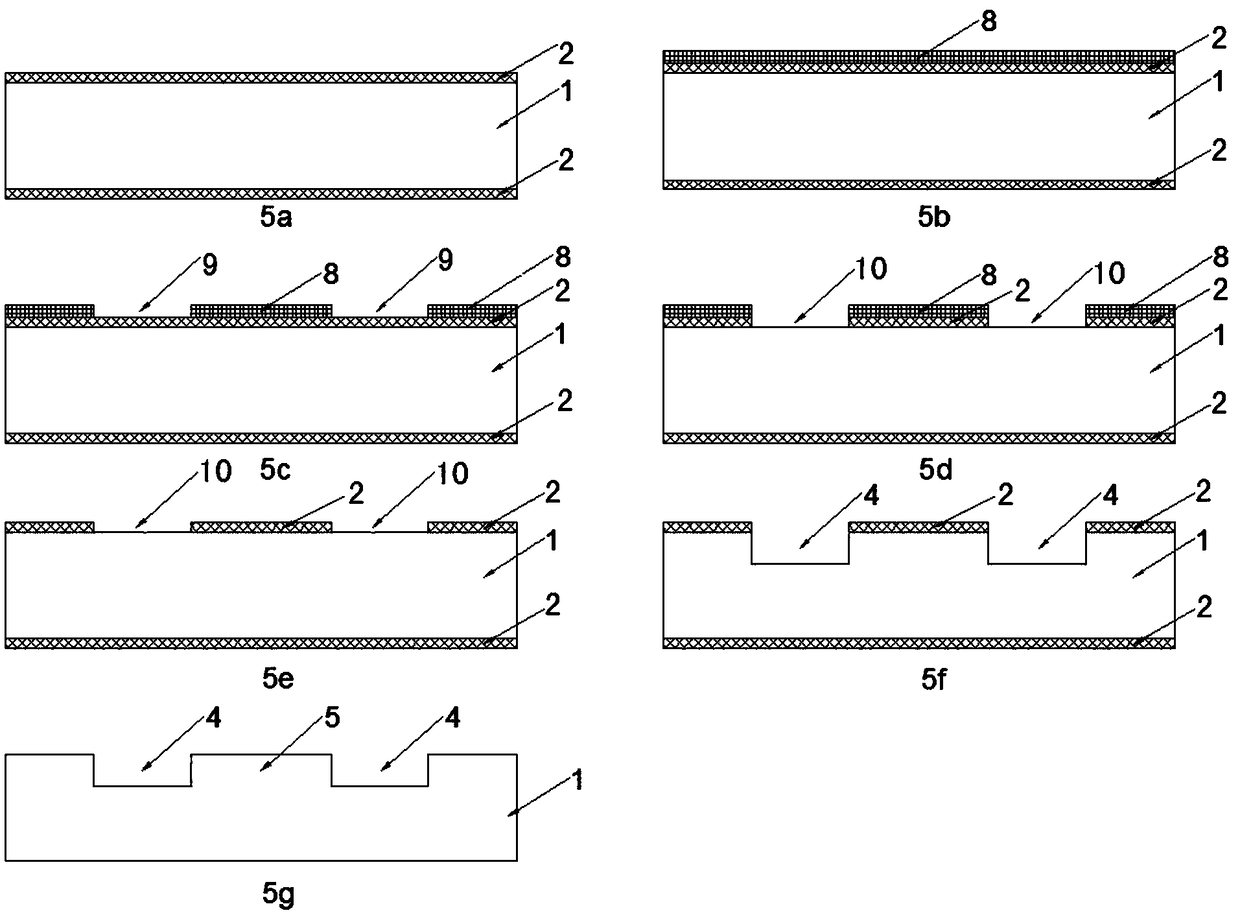

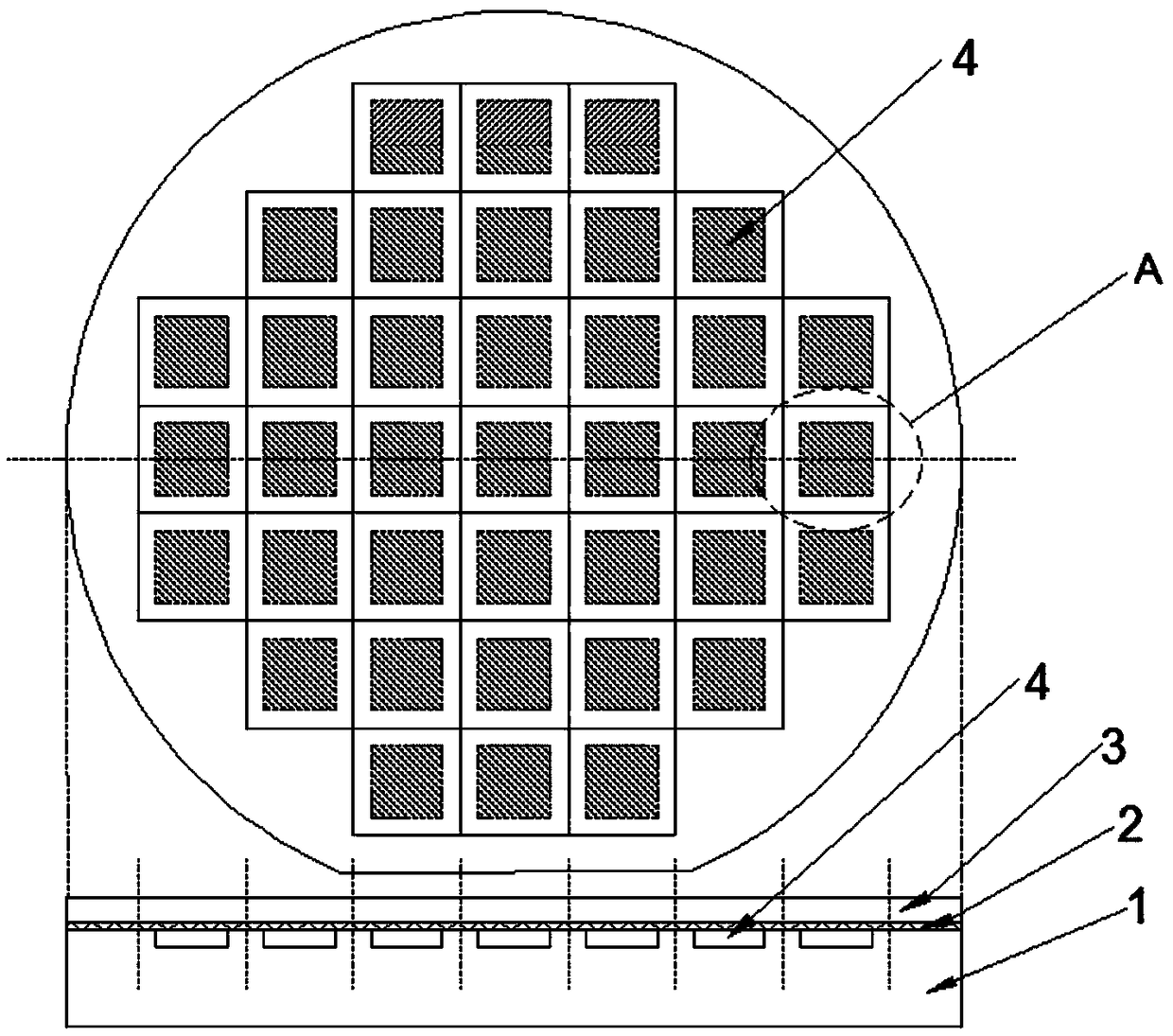

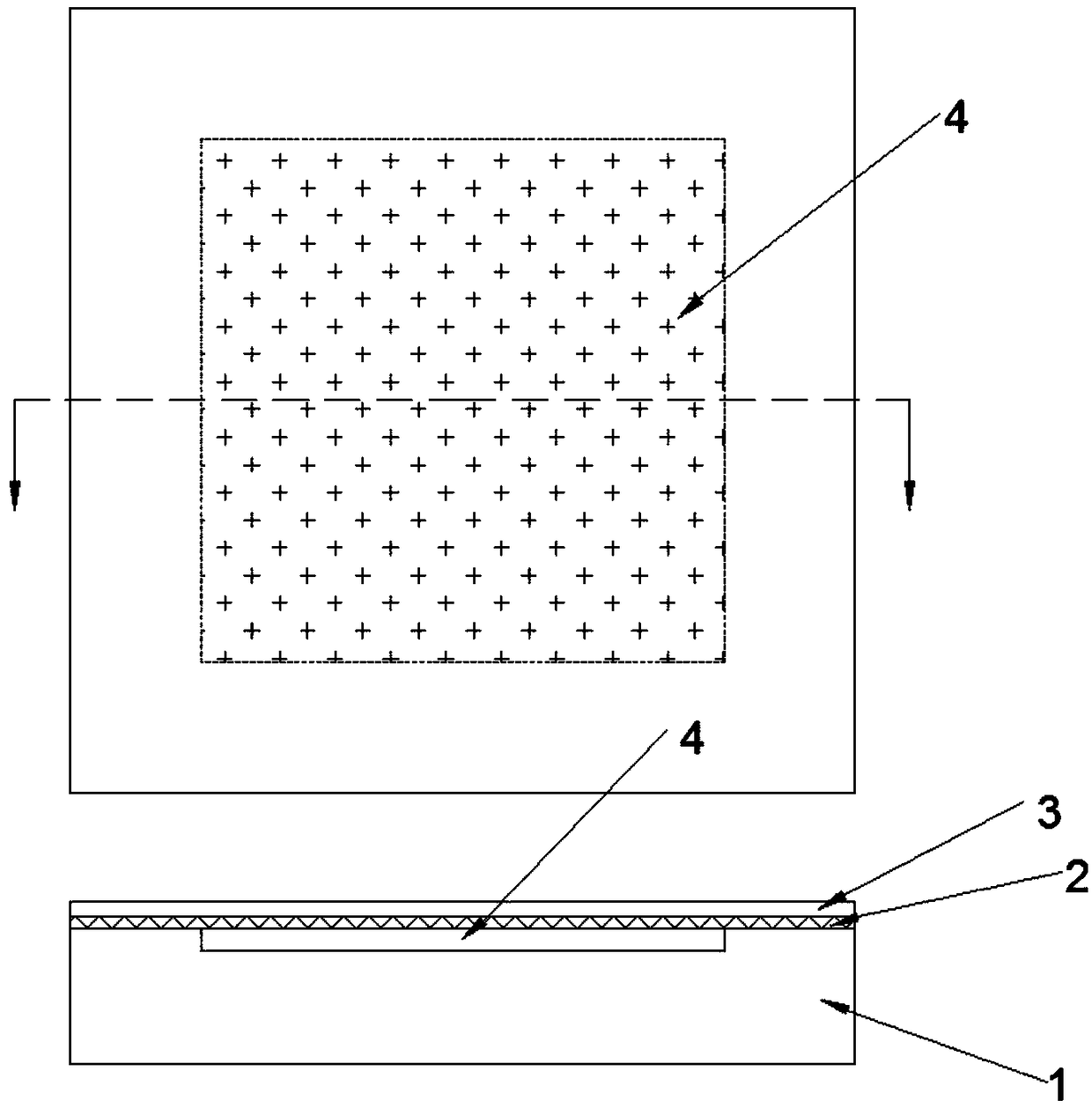

[0061] Such as Figure 5 Shown, the present invention discloses a kind of preparation method of MEMS SOI wafer, comprises the following steps:

[0062] (a) Preparation of the substrate 1: the commonly used semiconductor wafer is cleaned by a standard semiconductor process and then set aside;

[0063] (b) Fabrication of grooves on the substrate: on the substrate 1, grooves and support structures 5 are formed by dry etching or wet etching, and the grooves are cavities 4;

[0064] (c) Preparation of the device layer wafer 6: select a conventional semiconductor wafer, such as an N-type (100) silicon wafer;

[0065] (d) Fabrication of the dielectric layer 2 on the device layer wafer 6: a layer of dielectric layer 2 is grown on the device layer wafer 6 by thermal oxidation or chemical vapor deposition to form a device layer wafer with a dielectric layer 2 on both sides 6;

[0066] (e) Bonding of the device layer wafer 6 to the substrate 1: the device layer wafer 6 with the dielec...

Embodiment 1

[0070] There are three methods for making grooves on the substrate in step (b), one of which is as Image 6 shown, including:

[0071] (4a) Spin-coat a layer of photoresist 8 on the substrate 1, bake and solidify, as a mask layer for dry etching the substrate 1;

[0072] (4b) Photoetching and developing the opening 9 of the dry-etched substrate;

[0073] (4c) dry etching the substrate from the opening 9 to form grooves and support structures;

[0074] (4d) Removing the photoresist to form a substrate 1 with grooves (ie cavities 4 ) and support structures 5 .

Embodiment 2

[0076] The second manufacturing method of the groove on the substrate in step (b) is as follows: Figure 7 shown, including:

[0077] (5a) growing a dielectric layer 2 on the substrate 1 by thermal oxidation or chemical vapor deposition as a mask layer for dry etching the substrate;

[0078] (5b) The substrate 1 with the dielectric layer 2 is spin-coated with a layer of photoresist 8, and baked and cured;

[0079] (5c) Photoetching and developing the opening 9 of the dielectric layer 2 by dry etching or wet etching;

[0080] (5d) etching away the dielectric layer 2 at the opening 9 by wet etching or dry etching to form the second opening 10 of the substrate 1 by dry etching;

[0081] (5e) removing photoresist 8;

[0082] (5f) dry etching the substrate 1 from the second opening to form a groove (ie cavity 4) and a supporting structure 5;

[0083] (5g) Wet etching the dielectric layer 2 on the substrate 1 to form the substrate 1 with grooves (ie cavities 4 ) and support stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com