Organic fertilizer and preparation method thereof

An organic fertilizer and organic fertilizer technology, applied in the field of organic fertilizer and its preparation, can solve the problems of unable to meet the high yield of crops, low nutrient content, pollute the environment, etc., and achieve the effects of protecting people's health, huge economic benefits, and a wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

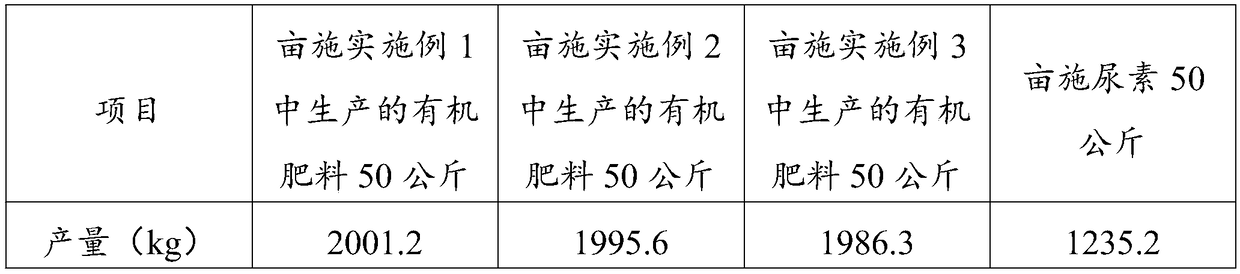

Examples

preparation example Construction

[0060] The present invention also provides a kind of preparation method of organic fertilizer, comprises the following steps:

[0061] Step 1. Send corn stalks, dried livestock and poultry manure, cake fertilizer, and humic acid to the crusher in turn for crushing, and then send them to the fermentation tank after crushing;

[0062] Step 2, adding organic fertilizer starter and appropriate amount of water (the weight ratio of organic fertilizer starter and water is 300:1) to the fermentation tank, stirring evenly, sealing and fermenting for 20-28 days;

[0063] Step 3. After the fermentation is completed, open the fermentation tank, add a sterilizing and deodorant to stir, and obtain an aqueous slurry of organic fertilizer after sterilization and deodorization;

[0064] Step 4: Dry the organic fertilizer aqueous slurry naturally, add amino acid chelate and humic acid chelate and stir evenly to obtain the finished product.

Embodiment 1

[0066] The preparation of embodiment 1 organic fertilizer

[0067] 50kg of corn stalks, 19kg of dried livestock and poultry manure, 6kg of cake fertilizer, and 29kg of humic acid are sequentially sent to the crusher for crushing, and then sent to the fermentation tank after crushing; add 1.5kg of organic fertilizer starter and appropriate amount of water to the fermentation tank, Stir evenly, seal and ferment for 25 days; after the fermentation is completed, open the fermentation tank, add 2kg of sterilizing and deodorant to stir, and obtain the organic fertilizer water-containing slurry after sterilization and deodorization; dry the organic fertilizer water-containing slurry naturally and add 3kg Mix the amino acid chelate and 1.5kg humic acid chelate evenly to get the organic fertilizer.

Embodiment 2

[0068] The preparation of embodiment 2 organic fertilizer

[0069] Send 45kg of corn stalks, 17kg of dried livestock and poultry manure, 5.5kg of cake fertilizer, and 25kg of humic acid into the crusher for crushing, and then send them to the fermentation tank; add 1kg of organic fertilizer starter and appropriate amount of water to the fermentation tank, Stir evenly, seal and ferment for 28 days; after the fermentation is completed, open the fermentation tank, add 3kg of sterilizing and deodorant to stir, and obtain the organic fertilizer water-containing slurry after sterilization and deodorization; dry the organic fertilizer water-containing slurry naturally and then add 4kg Mix the amino acid chelate and 1.5kg humic acid chelate evenly to get the organic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com