Method for producing eco-friendly cellulose acetate compound

A technology of cellulose acetate and compounds, which is applied in the field of preparation of environment-friendly cellulose acetate compounds, can solve the problems of harmful working environment, difficulty in producing products with the same shape, and low efficiency, so as to increase thermalization temperature and reduce adverse factors , The effect of reducing material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

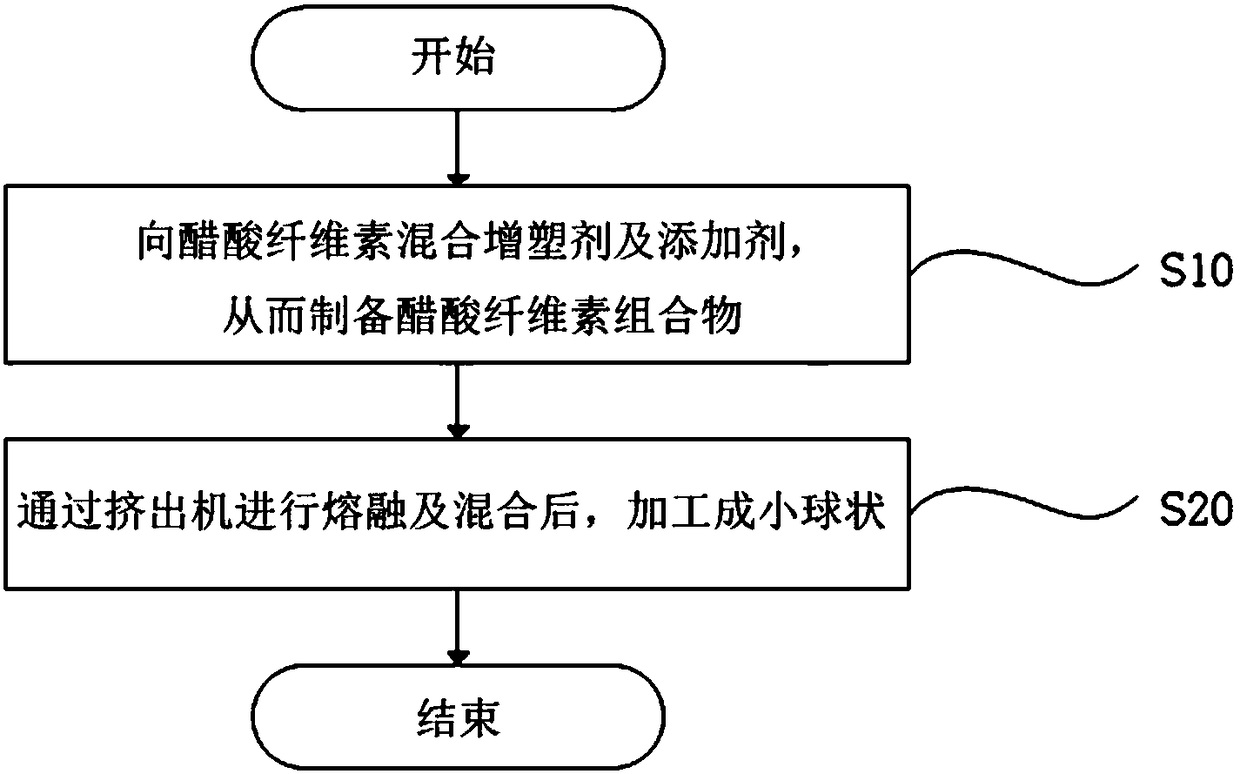

[0028] figure 1 It is a process diagram of a preparation method of a cellulose acetate compound according to an embodiment of the present invention. refer to figure 1 , The method for preparing a cellulose acetate compound according to an embodiment of the present invention includes: step S10, preparing a cellulose acetate composition; and step S20, processing into a pellet (Pellet).

[0029] In step S10, a plasticizer and additives are mixed with the cellulose acetate to prepare a cellulose acetate composition.

[0030] First, prepare cellulose acetate. Cellulose acetate is in powder form, so the water should be removed. Moisture removal can usually be carried out in a drying cabinet at a lower temperature than the processing temperature. In the subsequent extrusion operation, if the drying is insufficient, water vapor will be generated, resulting in foaming, and the powder will stick to the inside of the hopper, which may lead to unsatisfactory supply of raw materials....

Embodiment 1

[0055] In Example 1, 100g of CA398-30 and 10g of CDP were mixed, then the temperature of the extruder (adapter-die-cylinder-screw) was set to 215-210-210-210°C, and extruded After forming, pellets were produced using a shearing machine. At this time, the speed of the main screw, the speed of the feeder screw and the speed of the cutting screw are 283, 21, and 8 rpm, respectively. As a result of manufacturing in Example 1, it was difficult to control the speed of each screw at the initial stage, and when the residence time on the screw became longer, discoloration occurred over time. When no discoloration occurs, it maintains a relatively transparent gloss.

Embodiment 2

[0057] In embodiment 2, mixed the CDP of CA398-30, 10g of 100g, pigment, heat stabilizer (BZ-170T 2g), then the temperature of extruder (adapter-mold-cylinder-screw) is respectively set to 215-210-210-210 ℃, and after extrusion molding, the pellets were made by shearing machine. At this time, the speed of the main screw, the speed of the feeder screw and the speed of the cutting screw were 290, 20, and 8 rpm, respectively. In Example 2, the effect of suppressing thermal decomposition by adding a thermal stabilizer was confirmed. Extrusion properties are good, stretchable and maintain an overall uniform shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com