Waterproof putty powder used in low-temperature environment and preparation process of waterproof putty powder

A low temperature environment, putty powder technology, applied in the direction of filling slurry, etc., can solve the problems of low cost, low toughness and tensile strength, freeze cracking of putty, etc., to reduce heat energy loss, improve toughness and tensile strength, and reduce heat The effect of the exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The waterproof putty powder used in low temperature environment is composed of 90% putty powder base material, 6% antifreeze and 4% heat preservation agent.

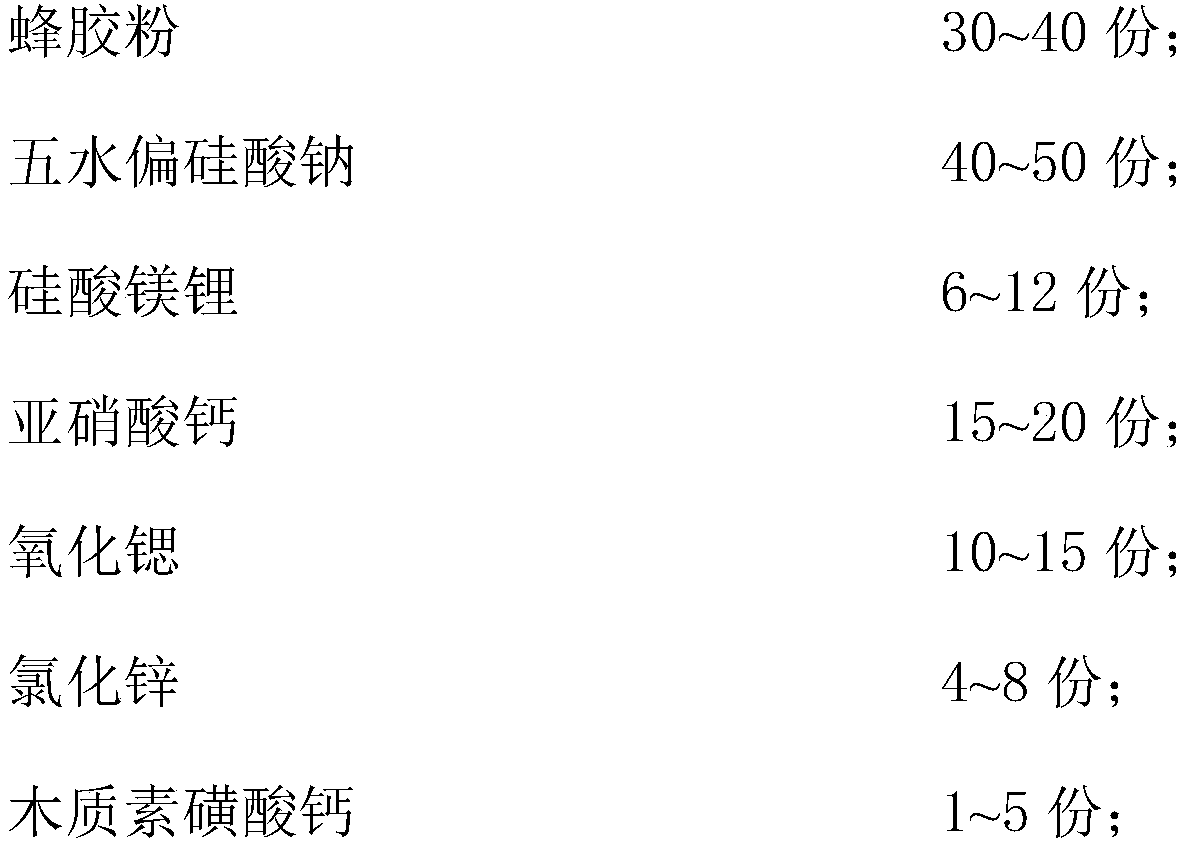

[0033] Above-mentioned antifreezing agent comprises following components by weight:

[0034]

[0035]

[0036] The above-mentioned thermal insulation agent comprises the following components in parts by weight:

[0037]

[0038] Preferably, the putty powder base material comprises the following components in parts by weight:

[0039]

[0040] The preparation process of the waterproof putty powder used in the above-mentioned low temperature environment comprises the following specific steps:

[0041] S1: Mix propolis powder, sodium metasilicate pentahydrate, lithium magnesium silicate, calcium nitrite, strontium oxide, zinc chloride, and calcium lignosulfonate, and dry at 70°C for 1 hour to obtain antifreeze;

[0042] S2: At 200°C, ceramic hollow microspheres with a particle size of 20 μm, sepiolite w...

Embodiment 2

[0046] Waterproof putty powder used in low temperature environment, said waterproof putty powder is composed of 86% putty powder base material, 8% antifreeze, 6% heat preservation agent;

[0047] Wherein, antifreezing agent comprises following components by weight:

[0048]

[0049] The insulating agent comprises the following components in parts by weight:

[0050]

[0051] Preferably, the putty powder base material comprises the following components in parts by weight:

[0052]

[0053] Preparation technology is with embodiment 1, difference is:

[0054] S1: The drying temperature is 75°C;

[0055] S2: The particle size of ceramic hollow microspheres is 25 μm, the particle size of sepiolite wool is 12.5 μm, the length of aluminum borosilicate whiskers is 12.5 μm, the diameter is 0.75 μm, the particle size of silica airgel is 0.25 μm, The sintering temperature is 225°C, and the freezing temperature is -50°C;

Embodiment 3

[0058] Waterproof putty powder used in low temperature environment, said waterproof putty powder is composed of 82% putty powder base material, 10% antifreeze, and 8% heat preservation agent;

[0059] Wherein, antifreezing agent comprises following components by weight:

[0060]

[0061] The insulating agent comprises the following components in parts by weight:

[0062]

[0063] Preferably, the putty powder base material comprises the following components in parts by weight:

[0064]

[0065]

[0066] Preparation technology is with embodiment 1, difference is:

[0067] S1: The drying temperature is 80°C;

[0068]S2: The particle size of ceramic hollow microspheres is 30 μm, the particle size of sepiolite wool is 15 μm, the length of aluminum borosilicate whiskers is 15 μm, the diameter is 1 μm, the particle size of silica airgel is 0.5 μm, and the sintering temperature is 250°C, the freezing temperature is -55°C;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com