Anti-rust coating for precision castings

An anti-rust coating and precision casting technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of loss of angular structure of castings, affecting the accuracy of casting surface dimensions, increasing workload, etc., to achieve Effects of prolonging service life, strong rust resistance, and improving lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

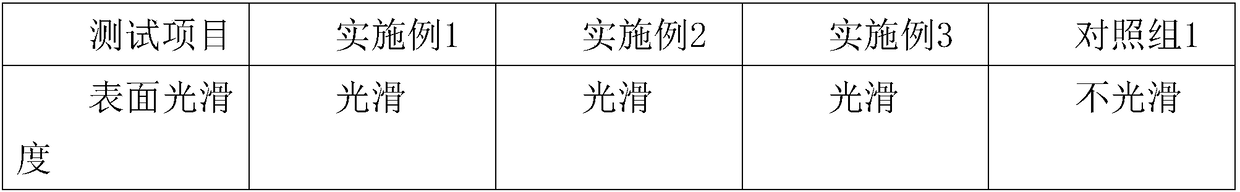

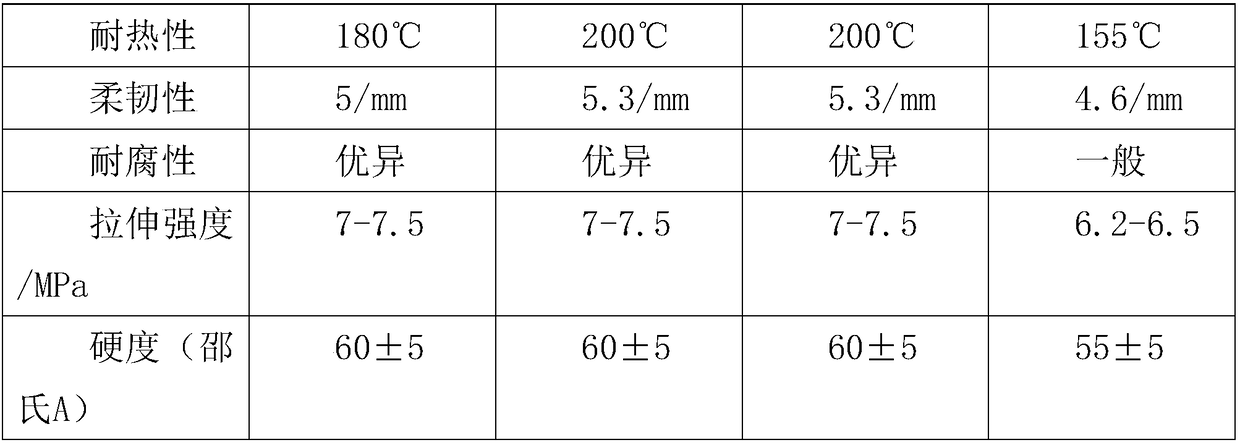

Examples

Embodiment 1

[0021] An antirust coating for precision castings, made of the following raw materials in parts by weight: 30 parts of phenolic resin, 8 parts of polyurethane emulsion, 5 parts of modified ceramic rubber powder, 3 parts of palm wax, 3 parts of titanium dioxide, 5 parts of methyl cellulose, 2 parts of ethyl acetate, 0.8 parts of calcium fluoride phosphate, 1 part of coupling agent, 0.5 parts of leveling agent.

[0022] The coupling agent is selected from a silane coupling agent or a titanate coupling agent.

[0023] The modified ceramic rubber powder is prepared by modifying ceramic fiber, silicone resin, and polyacrylamide emulsion. The modification method is: add silicone resin to the ceramic fiber, mix well and use frequency 2250MHz, power 800W Microwave reflux treatment for 10 minutes, then add polyacrylamide emulsion, mix evenly and continue microwave reflux treatment for 5 minutes, and transfer to 5°C environment to seal and stand for 30 minutes, stir with a mixer at a sp...

Embodiment 2

[0031] A kind of antirust paint for investment castings, made of the following raw materials in parts by weight:

[0032] 45 parts of phenolic resin, 12 parts of polyurethane emulsion, 8 parts of modified ceramic rubber powder, 5 parts of palm wax, 4 parts of titanium dioxide, 7 parts of methyl cellulose, 3 parts of ethyl acetate, 1.5 parts of calcium fluorophosphate, coupling agent 1.3 parts, 0.8 parts of leveling agent.

[0033] The coupling agent is selected from a silane coupling agent or a titanate coupling agent.

[0034] The modified ceramic rubber powder is prepared by modifying ceramic fiber, silicone resin, and polyacrylamide emulsion. The modification method is: add silicone resin to the ceramic fiber, mix well and use frequency 2250MHz, power 800W Microwave reflux treatment for 15 minutes, then add polyacrylamide emulsion, mix evenly and continue microwave reflux treatment for 10 minutes, and transfer to 10°C environment to seal and stand for 30 minutes, stir with...

Embodiment 3

[0042] An antirust coating for precision castings, made of the following raw materials in parts by weight: 60 parts of phenolic resin, 15 parts of polyurethane emulsion, 10 parts of modified ceramic rubber powder, 6 parts of palm wax, 5 parts of titanium dioxide, 8 parts of methyl cellulose, 5 parts of ethyl acetate, 2 parts of calcium fluoride phosphate, 1.5 parts of coupling agent, 1 part of leveling agent.

[0043] The coupling agent is selected from a silane coupling agent or a titanate coupling agent.

[0044] The modified ceramic rubber powder is prepared by modifying ceramic fiber, silicone resin, and polyacrylamide emulsion. The modification method is: add silicone resin to the ceramic fiber, mix well and use frequency 2250MHz, power 800W Microwave reflux treatment for 20 minutes, then add polyacrylamide emulsion, mix evenly and continue microwave reflux treatment for 10 minutes, and transfer to 10°C environment to seal and stand for 30 minutes, stir with a mixer at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com