Preparation of graphene/graphite-like phase carbon nitride composite material and application of composite material as solid lubricant

A graphene, graphene sheet technology, applied in lubricating compositions, additives, petroleum industry and other directions, can solve problems such as no lubricating friction practice, achieve good synergistic effect, high batch stability, simple and feasible preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh a certain amount of melamine into the crucible (filling degree 50%); cover the crucible and put it into the muffle furnace, heat up to 600°C at a rate of 3°C / min, keep it warm and calcine for 2 hours; The sample is naturally cooled to room temperature, and the product gC is collected 3 N 4 powder;

[0028] (2) Change g-C 3 N 4 The powder is put into a high-energy ball mill (filling degree 40%), and g-C is reduced by high-energy ball milling method (dry grinding method) 3 N 4 Powder grinding and refining; grinding speed is 260 rpm, grinding time is 90 minutes;

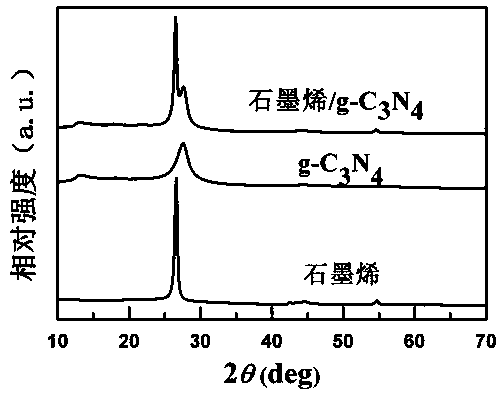

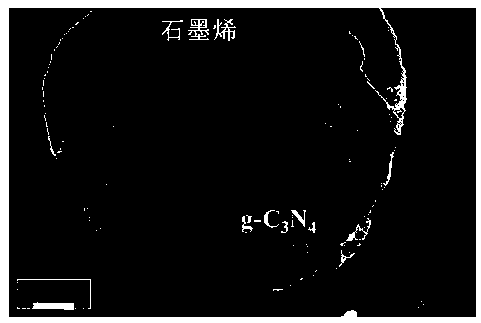

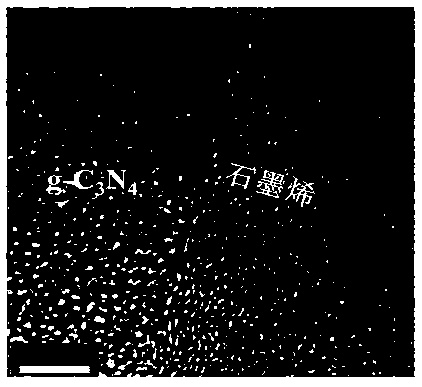

[0029] (3) Refine graphene and g-C 3 N 4 Mix according to the mass ratio of 1:3, and put it into a high-energy ball mill (filling degree 40%), and grind by the high-energy ball milling method (dry milling method) at a grinding speed of 260 rpm and a grinding time of 90 minutes to obtain graphene / g-C 3 N 4 Composite powder.

[0030] According to the foregoing method, the graphene / g-C obtained in this example 3 ...

Embodiment 2

[0032] (1) Weigh a certain amount of melamine into the crucible (filling degree 30%); cover the crucible and put it into the muffle furnace, heat up to 550°C at a rate of 3°C / min, keep it warm and calcine for 4 hours; The sample is naturally cooled to room temperature, and the product gC is collected 3 N 4 powder;

[0033] (2) Change g-C 3 N 4 The powder is put into a high-energy ball mill (filling degree 40%), and g-C is reduced by high-energy ball milling method (dry grinding method) 3 N 4 Powder grinding and refinement; grinding speed is 200 revolutions / min, grinding time is 180 minutes;

[0034] (3) Refine graphene and g-C 3 N 4 Mix at a mass ratio of 1:1 and put it in a high-energy ball mill (filling degree 40%), and grind by high-energy ball milling (dry milling) at a grinding speed of 200 rpm and a grinding time of 180 minutes to obtain graphene / g-C 3 N 4 Composite powder.

[0035] According to the foregoing method, the graphene / g-C obtained in this example 3 N 4 Tribological ...

Embodiment 3

[0037] (1) Weigh a certain amount of melamine into the crucible (filling degree 50%); cover the crucible and put it into the muffle furnace, heat up to 650°C at a rate of 5°C / min, keep warm and calcine for 1.5 hours; The sample is naturally cooled to room temperature, and the product gC is collected 3 N 4 powder;

[0038] (2) Change g-C 3 N 4 The powder is put into a high-energy ball mill (filling degree 30%), and g-C is reduced by high-energy ball milling method (dry grinding method) 3 N 4 Powder grinding and refinement; grinding speed is 300 revolutions / min, grinding time is 60 minutes;

[0039] (3) Refine graphene and g-C 3 N 4 Mix according to the mass ratio of 1:5 and put it in a high-energy ball mill (filling degree 30%), and grind by high-energy ball milling (dry milling method) at a grinding speed of 300 revolutions / minute and grinding time for 60 minutes to obtain graphene / g-C 3 N 4 Composite powder.

[0040] According to the foregoing method, the graphene / g-C obtained in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com