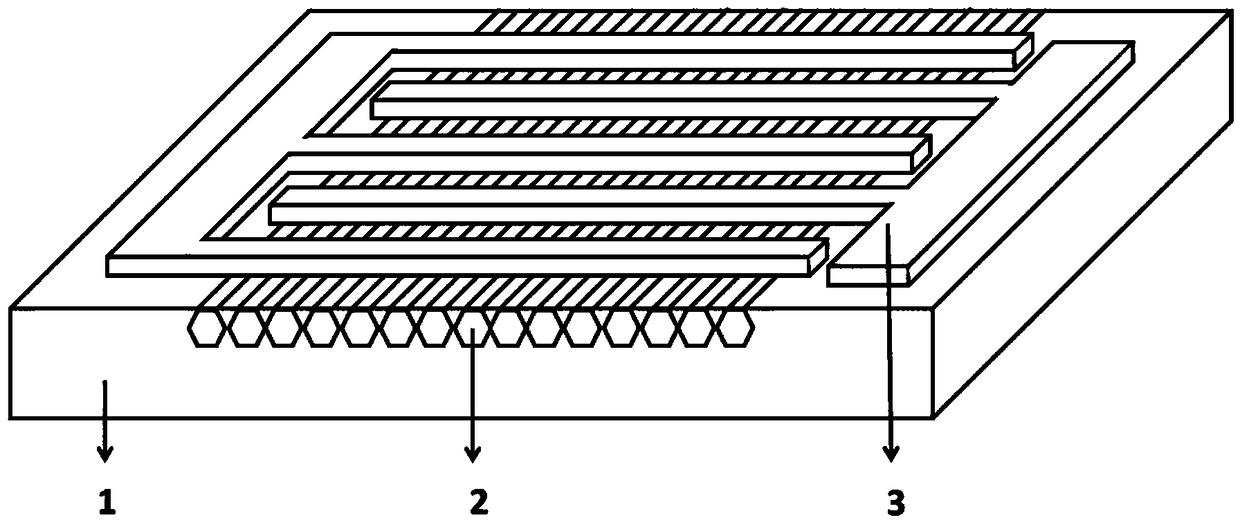

Preparation method of ultraviolet detector based on ZnO micro-wire array embedded in flexible substrate

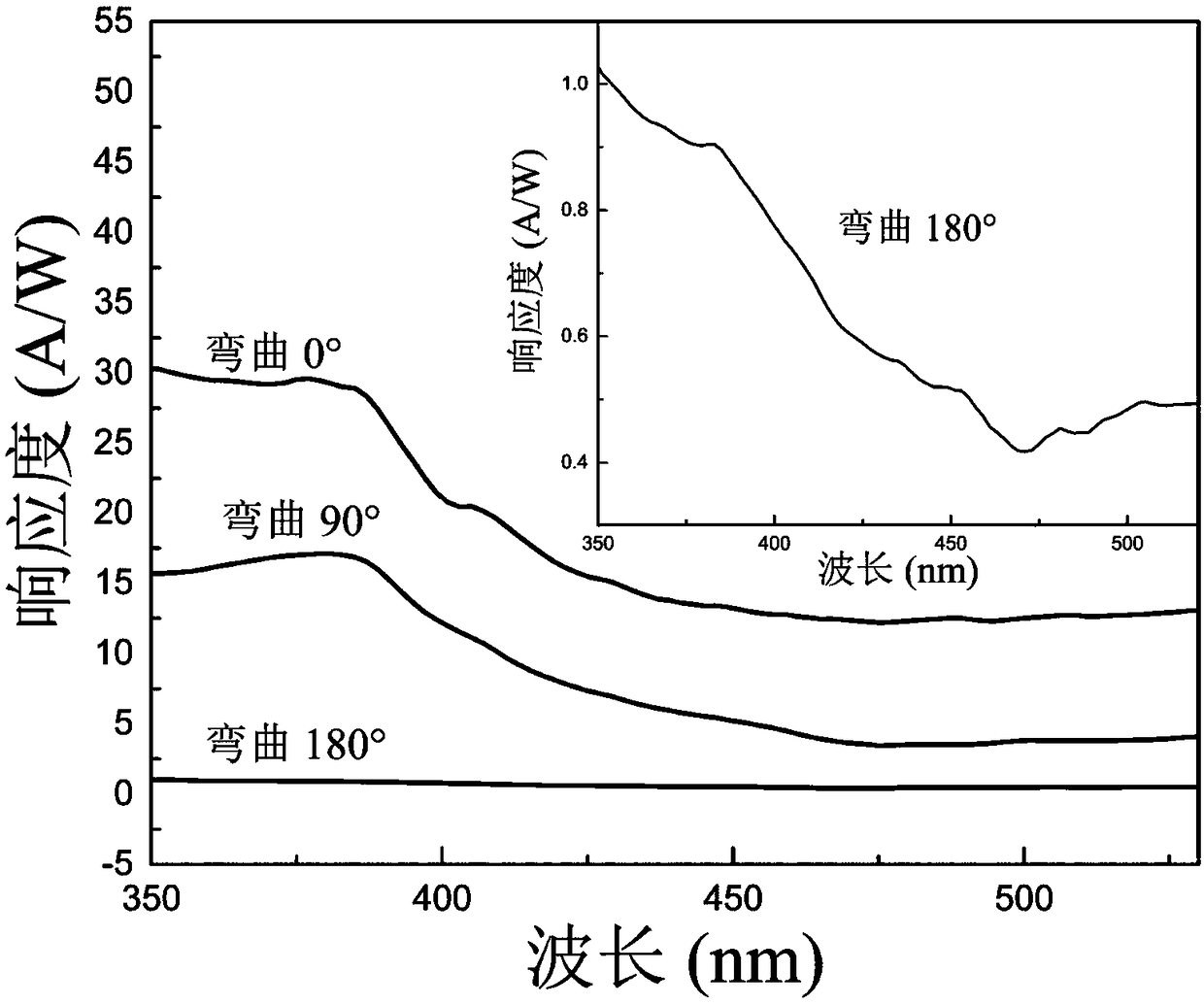

A technology of ultraviolet detector and flexible substrate, which is applied in the field of ultraviolet light detection, can solve the problems of low crystal quality, low synthesis temperature, difficult to control the shape of zinc oxide film, etc., and achieve good flexibility, simple operation, and small bending radius Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing a ZnO micron line array ultraviolet detector embedded in a flexible substrate, the method comprising the following steps:

[0032] S1. Carry out cleaning and drying pretreatment on the quartz test tube and the quartz boat, and use distilled water, acetone, and ethanol to perform ultrasonic cleaning on the quartz test tube and the quartz boat respectively, and dry them for use;

[0033] S2. Take 5 grams of zinc powder with a purity of 99.99%, evenly spread it on the bottom of the cleaned quartz boat and place the quartz boat in the quartz test tube, and place the quartz test tube in the high temperature area in the middle of the tube furnace;

[0034] S3. Raise the temperature of the tube furnace to 980 °C at a heating rate of 10 °C / min, and continuously feed high-purity nitrogen at a flow rate of 15 ml / min as a protective gas during the heating process of the tube furnace. When the temperature of the tube furnace reaches th...

Embodiment 2

[0041]This embodiment provides a method for preparing a ZnO micron line array ultraviolet detector embedded in a flexible substrate. The experimental conditions are the same as in Embodiment 1, except that in step S2, 7 grams of zinc powder with a purity of 99.99% is weighed, and step S3 In this process, the tube furnace is heated up to 1000 °C at a heating rate of 15 °C / min, and high-purity nitrogen is continuously fed into the tube furnace at a flow rate of 20 ml / min as a protective gas during the heating process. When the tube furnace is heated to this temperature , stop feeding nitrogen, and start feeding high-purity oxygen at a flow rate of 20ml / min, and keep the temperature for 1.5h; in step S6, after dropping 1ml of PVAL glue to cover the surface of the zinc oxide micron wire array, put it in a drying oven at 65°C The box is kept for 1.5h.

Embodiment 3

[0043] This embodiment provides a method for preparing a ZnO micron line array ultraviolet detector embedded in a flexible substrate. The experimental conditions are the same as in Embodiment 1, except that in step S2, 10 grams of zinc powder with a purity of 99.99% is weighed, and step S3 In the process, the tube furnace was heated up to 990 °C at a heating rate of 13 °C / min, and high-purity nitrogen was continuously fed in at a flow rate of 17 ml / min as a protective gas during the heating process of the tube furnace. , stop feeding nitrogen, and start feeding high-purity oxygen at a flow rate of 17ml / min, and keep the temperature for 1.3h; in step S6, after dropping 1.5ml of PVAL glue to cover the surface of the zinc oxide micron wire array, put it in a 63°C Keep in the drying box for 1.3h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com