Preparation method of iron phosphide nanosheet and biomass carbon composite material and application

A biomass carbon and composite material technology, applied in electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of cumbersome process and high risk factor, and achieve the effects of simple process, improved cycle life and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Washing the leaves of Magnolia magnolia 2-3 times with a mixed solution of acetone and water. Dry in an oven at 60°C for 2 hours. Place the blade between graphite sheets, then anneal at 800°C for 2 hours, place in 3mol KOH aqueous solution for 2 hours, and place in 1mol / L HCl aqueous solution for 10 hours.

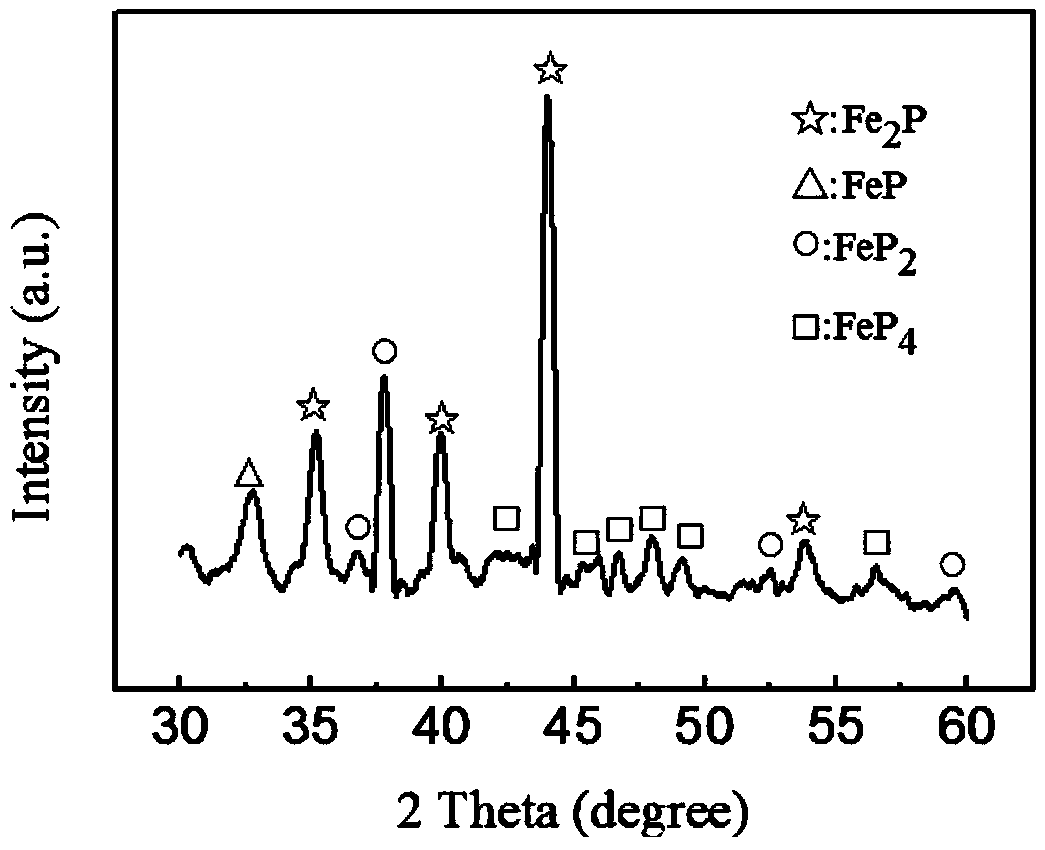

[0026] (2) The biomass carbon film obtained in step (1) is used as a working electrode, the platinum sheet is used as a counter electrode, and silver / silver chloride is placed in a sealed electrolytic cell as a reference electrode. Containing the ferric sulfate heptahydrate of 0.72mol / L, the sodium hypophosphite of 0.36mol / L, the glycine of 0.11mol / L, in the sealed electrolytic cell of the oxalic acid mixed electrolyte of 0.005mol / L, feed nitrogen after 15 minutes, A constant potential of -1.5 V was applied to the working electrode for 30 minutes for deposition. After electrodeposition, the working electrode was washed 2-3 times with deionized water. Amorphou...

Embodiment 2

[0032] (1) Washing the leaves of Magnolia magnolia 2-3 times with a mixed solution of acetone and water. Dry in an oven at 60°C for 2 hours. Put the blade in a tube furnace, feed nitrogen protective gas with an air intake of 0.2L / min, and heat up to 800°C at a rate of 2°C / min, keep it warm for 2 hours, and then naturally cool to room temperature to obtain biomass carbon membrane. Place in 3mol KOH aqueous solution for 2 hours, then place in 1mol / L HCl aqueous solution for 10 hours.

[0033] (2) The biomass carbon film obtained in step (1) is used as a working electrode, the platinum sheet is used as a counter electrode, and silver / silver chloride is placed in a sealed electrolytic cell as a reference electrode. Containing the ferric sulfate heptahydrate of 0.36mol / L, the sodium hypophosphite of 0.72mol / L, the glycine of 0.22mol / L, in the sealed electrolytic cell of the oxalic acid mixed electrolyte of 0.005mol / L, feed nitrogen after 15 minutes, A constant potential of -1.5 ...

Embodiment 3

[0037] (1) Washing the leaves of Magnolia magnolia 2-3 times with a mixed solution of acetone and water. Dry in an oven at 60°C for 2 hours. Put the blades in a tube furnace, feed nitrogen protective gas with an air intake of 0.2L / min, heat up to 800°C at a rate of 2°C / min, keep it warm for 2 hours, and then cool it down to room temperature naturally to obtain biomass carbon membrane. Place in 3mol KOH aqueous solution for 2 hours, then place in 1mol / L HCl aqueous solution for 10 hours.

[0038] (2) The biomass carbon film obtained in step (1) is used as a working electrode, the platinum sheet is used as a counter electrode, and silver / silver chloride is placed in a sealed electrolytic cell as a reference electrode. Containing the iron sulfate heptahydrate of 0.36mol / L, the sodium hypophosphite of 1.08mol / L, the glycine of 0.44mol / L, in the sealed electrolytic cell of the oxalic acid mixed electrolyte of 0.01mol / L, feed nitrogen after 15 minutes, A constant potential of -1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge and discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com