A rapid discharge method and discharge treatment equipment for waste lithium batteries

A waste lithium battery, fast technology, applied in the direction of secondary battery charging/discharging, battery recycling, secondary battery repair/maintenance, etc., can solve the problem of inability to further increase the discharge speed of waste batteries, poor ionic hydration layer damage ability, conductive Increased ion movement speed and other issues, to achieve the effect of weakening ion hydration, accelerating transmission speed, and accelerating discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

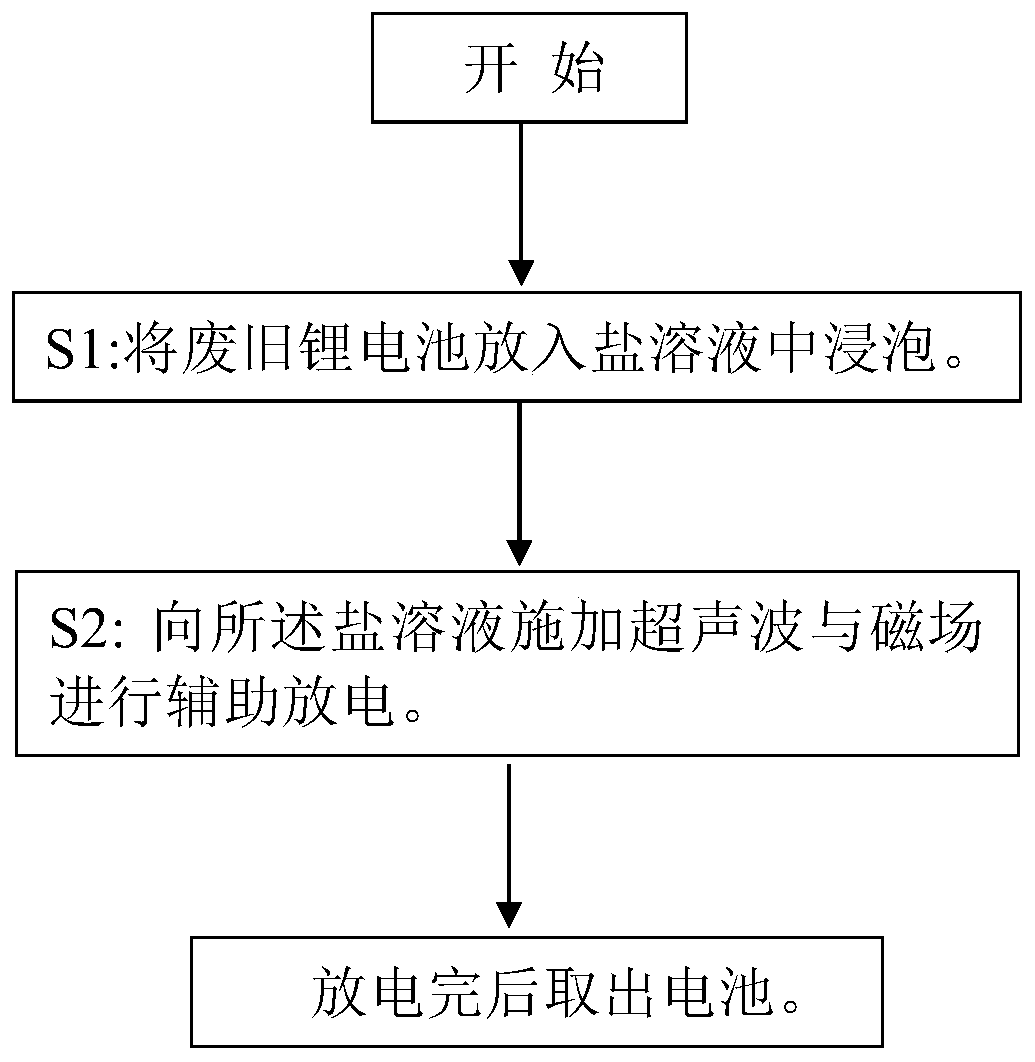

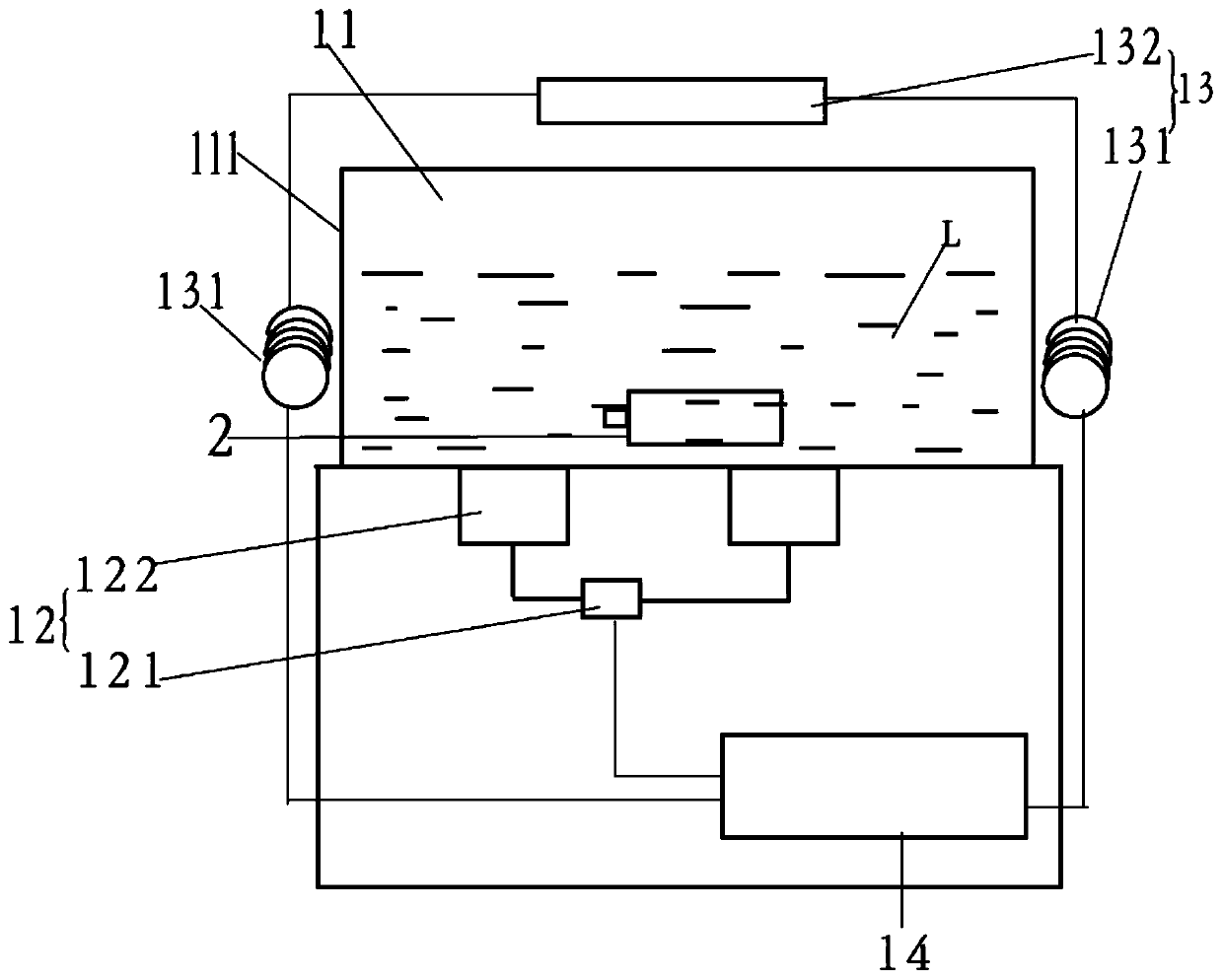

Method used

Image

Examples

experiment example

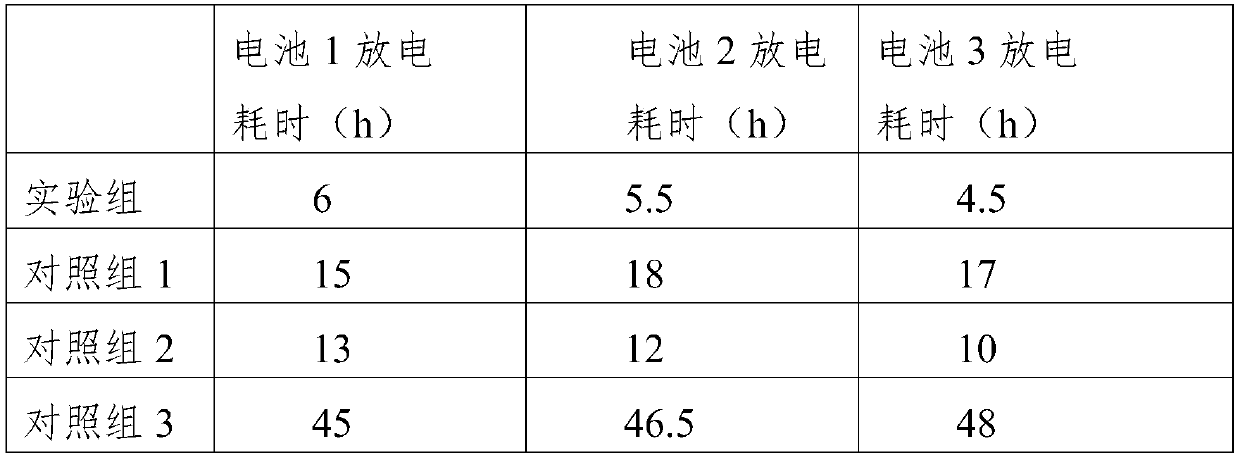

[0063] In order to further illustrate the technical effect of the present invention, the test and verification are carried out according to the above-mentioned experimental device model of the rapid discharge treatment equipment for waste lithium batteries.

[0064] Material preparation: 12 waste 18650 lithium batteries (diameter 18mm*65mm cylindrical battery), the remaining power is 0.9 ~ 1.0Ah, respectively remove the external plastic film and plastic shell; 1 KM-1030C laboratory small ultrasonic cleaning machine (40,000Hz) ; 5L sodium chloride solution 6mol / L; 1 pair of self-winding solenoids, ohmic resistance 30 ohms, power transformer (input 110 / 220V, output 24V, power 100W); voltmeter.

[0065] Test method: 12 batteries are divided into 4 groups, each with 3 batteries; the 4 groups of batteries correspond to the experimental group and the control group 1-3 respectively.

[0066] Carry out the following experimental steps in sequence:

[0067] Experimental group: put 3 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com