Preparation method of ultrasonic pre-treatment Chinese doughnut

A technology of ultrasonic wave and pretreatment, applied in the direction of dough processing, baking, fried food, etc., to achieve the effect of easy promotion, low oil content and reduced oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

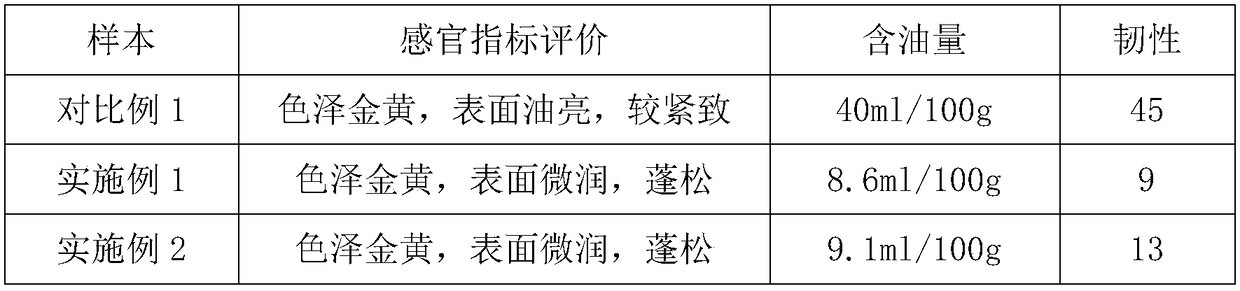

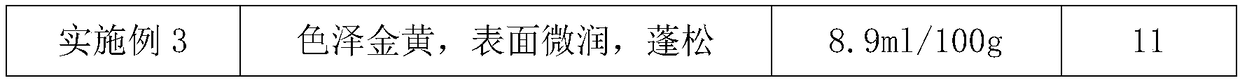

Examples

Embodiment 1

[0018] A preparation method for ultrasonic pretreatment twist, comprising the steps:

[0019] (1) Preparation of raw materials: Calculated by mass, prepare 500 parts of flour, 50 parts of eggs, 220 parts of milk, 3 parts of mixed starter, 1.2 parts of table salt, 10 parts of honey, 38 parts of crystallized fructose, and salad oil for frying Appropriate amount; wherein the mixed starter is a mixture of yeast powder and lactic acid bacteria powder at 3:1 by mass;

[0020] (2) Mix the flour, milk, eggs, salt, honey, and crystallized fructose prepared in step (1), add the mixed starter, use a vacuum dough mixer, and knead the dough for 9 minutes under the condition of vacuum degree -0.06mpa, and make the dough containing A loose dough with a smooth surface and a water content of 41%;

[0021] (3) Seal the dough reconciled in step (2) with plastic wrap, put it into a container, and then add distilled water at 30°C, the water is submerged 5cm above the dough; insert the ultrasonic ...

Embodiment 2

[0024] A preparation method for ultrasonic pretreatment twist, comprising the steps:

[0025] (1) Preparation of raw materials: Calculated by mass, prepare 750 parts of flour, 60 parts of eggs, 160 parts of milk, 5.5 parts of mixed starter, 3 parts of salt, 22 parts of honey, 29 parts of crystalline fructose, and salad oil for frying Appropriate amount; wherein the mixed starter is a mixture of yeast powder and lactic acid bacteria powder in a mass of 5.5:1;

[0026] (2) Mix the flour, milk, eggs, salt, honey, and crystallized fructose prepared in step (1), add the mixed starter, use a vacuum dough mixer, and knead the dough for 7 minutes under the condition of vacuum degree -0.08mpa to make the dough containing A loose dough with a smooth surface and a water content of 39%;

[0027] (3) Seal the dough reconciled in step (2) with plastic wrap, put it into a container, and then add distilled water at 32°C, the water is 4.5cm below the dough; insert the ultrasonic probe into th...

Embodiment 3

[0030] A preparation method for ultrasonic pretreatment twist, comprising the steps:

[0031] (1) Preparation of raw materials: Calculated by mass, prepare 620 parts of flour, 70 parts of eggs, 190 parts of milk, 4.5 parts of mixed starter, 2 parts of table salt, 28 parts of honey, 20 parts of crystalline fructose, and salad oil for frying Appropriate amount; wherein the mixed starter is a mixture of yeast powder and lactic acid bacteria powder in a mass of 4.5:1;

[0032] (2) Mix the flour, milk, eggs, salt, honey, and crystallized fructose prepared in step (1), add the mixed starter, use a vacuum dough mixer, and knead dough for 5.5 minutes under the condition of vacuum degree -0.095mpa, and make A loose dough with a smooth surface and a moisture content of 40%;

[0033] (3) Seal the dough reconciled in step (2) with plastic wrap, put it into a container, and then add distilled water at 30°C, the water is submerged 4cm above the dough; insert the ultrasonic probe into the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com