Ozone disinfection device for medical equipment

A technology for disinfection of medical equipment and ozone, which is applied in the direction of disinfection, dry gas arrangement, lighting and heating equipment, etc., can solve the problems of high cost, waste of energy, and reduce the amount of ozone dissolved in ozone water, so as to improve the heat dissipation effect and improve the electrolysis efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

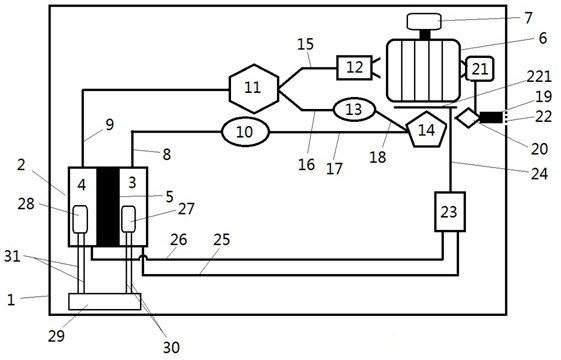

[0030] Attached below figure 1 The technical solutions of the present invention are further described through specific implementation methods.

[0031] An ozone disinfection device for medical instruments, comprising a box body 1, the box body is used to hold various equipment parts, an ozone generator 2 is arranged in the box body 1, and the ozone generator 2 includes a cathode water tank 3, an anode water tank 4 and an ozone electrolysis generator device 5, the ozone generating device 2 is connected with a corresponding electrolysis power supply; a medical device placement device 6 is provided in the box, and the medical device placement device 6 is provided with a rotating motor 7, and the rotating motor 7 can drive the medical instrument placement device 6 to rotate to get rid of the residual water drops on it after disinfection; the cathode water tank 3 is provided with a hydrogen gas outlet pipe 8, and the anode water tank 4 is provided with an ozone-oxygen mixed air out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com