Preparation method of ferromanganese component fine adjustable Prussian white mesomorphic material

A mesocrystalline and fine technology, applied in the direction of manganese halide, ferricyanide, metal cyanide, etc., can solve the problems of difficult to control the size and shape of Prussian white, the disordered size of Prussian white particles, uneven stability, etc., to achieve short cycle time, Non-perishable and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

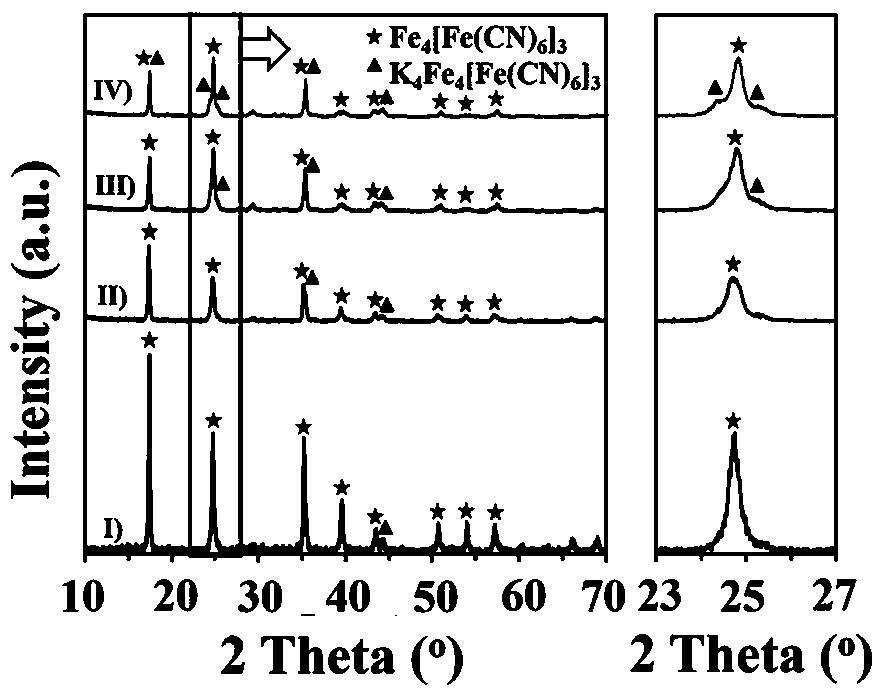

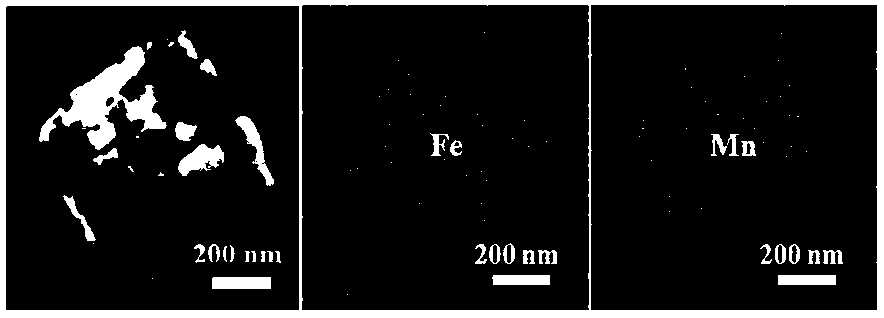

[0027] Ferromanganese component finely adjustable Prussian white (Mn II -PBA) Mesogenic material preparation:

[0028] (1) Dissolve 0.12 g of potassium ferrocyanide and 3.8 g of polyvinylpyrrolidone in 50 mL of 0.1M dilute hydrochloric acid solution, and stir at room temperature until the solid is completely dissolved to obtain a ferrous ion solution;

[0029] (2) Add 0.0358 g of manganese chloride solid to the above solution, Fe:Mn=1:1, stir until completely dissolved, and place in an ultrasonic machine for ultrasonic treatment for 30 minutes;

[0030] (3) Pour the ultrasonicated solution into a high-pressure reactor, heat it in water at 80°C for 24 hours, remove the supernatant after natural cooling, wash and centrifuge the precipitate with deionized water and ethanol three times each to obtain manganese-doped Prussia White;

[0031] (4) Vacuum-dry the Prussian white doped with manganese chloride for 12 h until the water evaporates completely at 60 °C to obtain Mn II -PBA...

Embodiment 2

[0034] The preparation method of this example is the same as that of Example 1, the low-valent manganate added is manganese formate, and the bimetallic Prussian mesogen is synthesized under other conditions unchanged.

[0035] Table 1 is the manganese chloride doping Prussian white (Mn II -PBA) spectral data

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com