A kind of antifreeze concrete pumping agent

A concrete pump and full mixing technology, which is applied in the field of building material manufacturing, can solve problems affecting concrete strength, engineering quality problems, and inconvenient construction, and achieve good antifreeze performance, good water reducing performance, and reduced slump loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

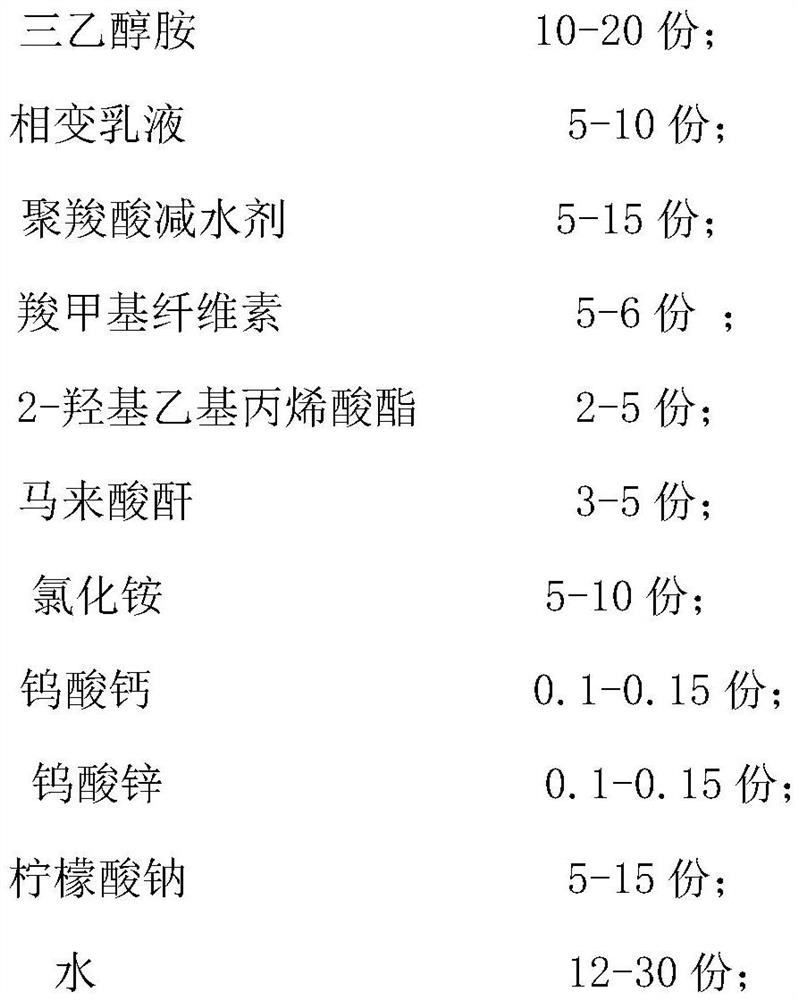

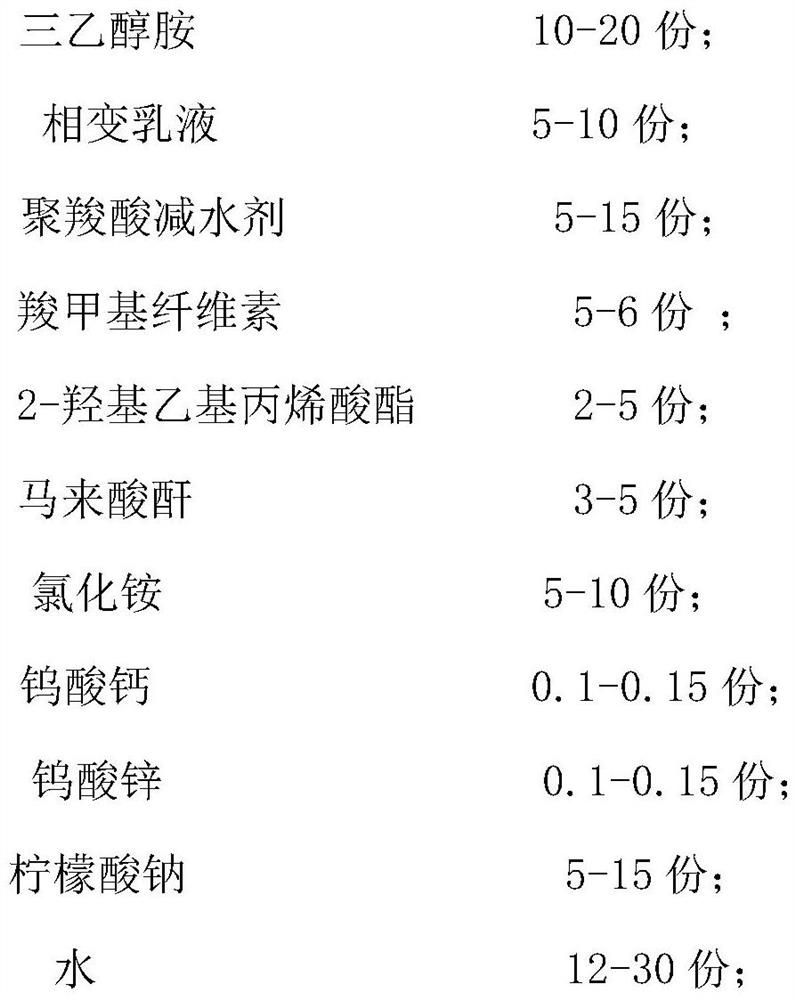

[0015] A kind of antifreeze type concrete pumping agent described in the present embodiment is made up of following raw materials in parts by weight,

[0016]

[0017]

[0018] The preparation method of the phase change emulsion is as follows: fully mix 12kg of hydroxy silicone oil, 2kg of sodium n-decane sulfonate and 30kg of water, place it in a shearing machine, and transfer it to 8000-1000 rpm, and the shearing time is 15 -30 minutes, slowly add 5 parts of hard fatty acid and 2 parts of palm oil dropwise to obtain a phase change emulsion.

Embodiment 2

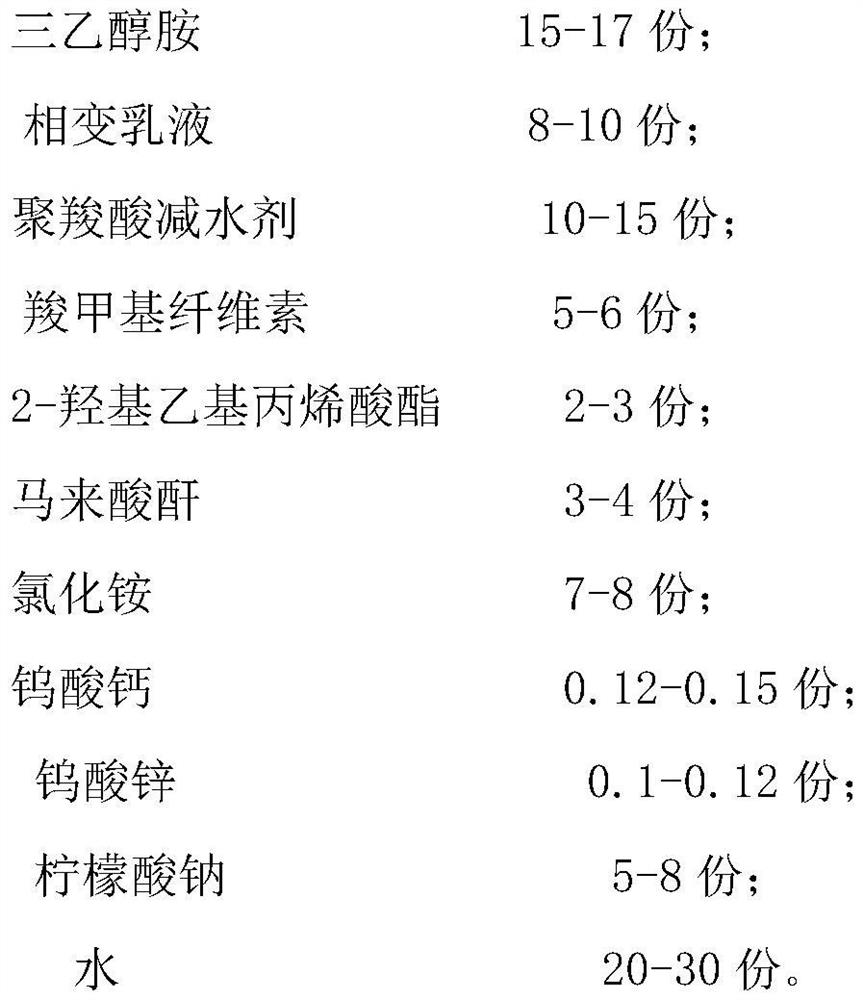

[0020] A kind of antifreeze type concrete pumping agent described in the present embodiment is made up of following raw materials in parts by weight,

[0021]

[0022] The preparation method of the phase change emulsion is as follows: fully mix 12kg of hydroxy silicone oil, 2kg of sodium n-decane sulfonate and 30kg of water, place it in a shearing machine, and transfer it to 8000-1000 rpm, and the shearing time is 15 -30 minutes, slowly add 5 parts of hard fatty acid and 2 parts of palm oil dropwise to obtain a phase change emulsion.

[0023] The performance indicators of the antifreeze concrete pumping agent obtained in Examples 1 and 2 are as shown in Table 1.

[0024]

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com