High-solid-content low-viscosity low-hydroxyl-value low-dilution-rate alkyd resin, and preparation method and applications thereof

A high-solid, low-viscosity, alkyd resin technology, applied in coatings, polyurea/polyurethane coatings, etc., to achieve the effect of reducing overall cost, reducing the content of free TDI, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

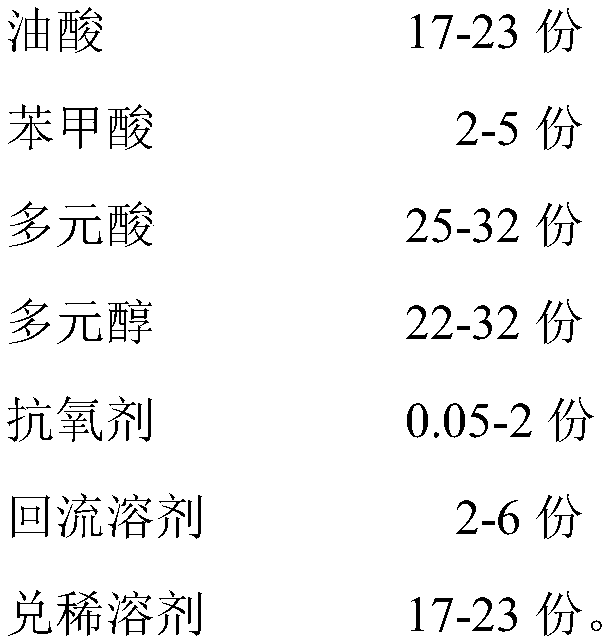

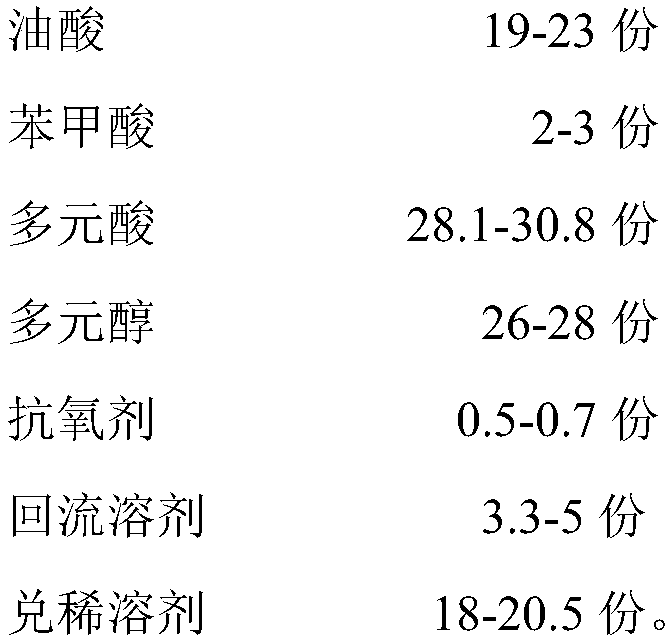

[0053] A high-solid, low-viscosity, low-hydroxyl, low-ratio alkyd resin is made of the following components by weight:

[0054] Oleic acid 21.2 parts

[0055] 2 parts benzoic acid

[0056] Polyacids:

[0057] 27.5 parts of phthalic anhydride

[0058] Maleic anhydride 1.5 parts

[0059] Polyol:

[0060] Pentaerythritol 13 parts

[0061] 3 parts trimethylolpropane

[0062] Propylene glycol 10 parts

[0063] Antioxidant:

[0064] Hypophosphorous acid 0.5 parts

[0065] Reflux solvent:

[0066] Xylene 3.3 parts

[0067] Dilute solvent:

[0068] Butyl acetate 18 parts

[0069] The preparation method of the above-mentioned high-solid, low-viscosity, low-hydroxyl and low-dilute alkyd resin comprises the following steps:

[0070] 1. Response.

[0071] Step 1: Weigh each raw material component according to the formula quantity, and set aside;

[0072] Step 2: 21.2 parts of oleic acid, 2 parts of benzoic acid, 27.5 parts of phthalic anhydride, 1.5 parts of maleic anhydrid...

Embodiment 2

[0079] A high-solid, low-viscosity, low-hydroxyl, low-ratio alkyd resin is made of the following components by weight:

[0080] 22 parts of oleic acid

[0081] 2.5 parts of benzoic acid

[0082] Polyacids:

[0083] 28 parts of phthalic anhydride

[0084] Maleic anhydride 1.4 parts

[0085] Polyol:

[0086] Pentaerythritol 14 parts

[0087] Trimethylolpropane 3.5 parts

[0088] Diethylene glycol 10.5 parts

[0089] Antioxidant:

[0090] Hypophosphorous acid 0.4 parts

[0091] Phosphite antioxidant 0.2 parts

[0092] Reflux solvent:

[0093] 4 parts xylene

[0094] Dilute solvent:

[0095] Butyl acetate 19 parts

[0096] The preparation method of the above-mentioned high-solid, low-viscosity, low-hydroxyl and low-dilute alkyd resin comprises the following steps:

[0097] 1. Response.

[0098] Step 1: Weigh each raw material component according to the formula quantity, and set aside;

[0099] Step 2: 22 parts of oleic acid, 2.5 parts of benzoic acid, 28 parts of p...

Embodiment 3

[0106] A high-solid, low-viscosity, low-hydroxyl, low-ratio alkyd resin is made of the following components by weight:

[0107] Oleic acid 19 parts

[0108] 3 parts benzoic acid

[0109] Polyacids:

[0110] 28.5 parts of phthalic anhydride

[0111] 2 parts maleic anhydride

[0112] Polyol:

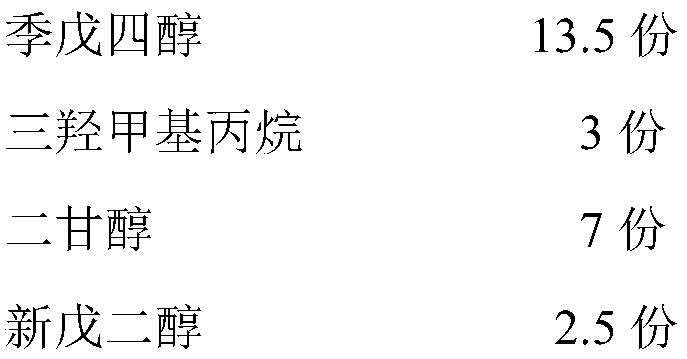

[0113] Pentaerythritol 13.5 parts

[0114] Trimethylolpropane 3.8 parts

[0115] Ethylene glycol 10.8 parts

[0116] Antioxidant:

[0117] Hypophosphorous acid 0.2 part

[0118] Multivariate hindered aminophenol antioxidant 0.4 parts

[0119] Reflux solvent:

[0120] Xylene 4.5 parts

[0121] Dilute solvent:

[0122] Butyl acetate 18 parts

[0123] Propylene glycol methyl ether acetate 2 parts

[0124] The preparation method of the above-mentioned high-solid, low-viscosity, low-hydroxyl and low-dilute alkyd resin comprises the following steps:

[0125] 1. Response.

[0126] Step 1: Weigh each raw material component according to the formula quantity, and set aside;

[0127]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com