Cooling system applied to urea dewaxing process

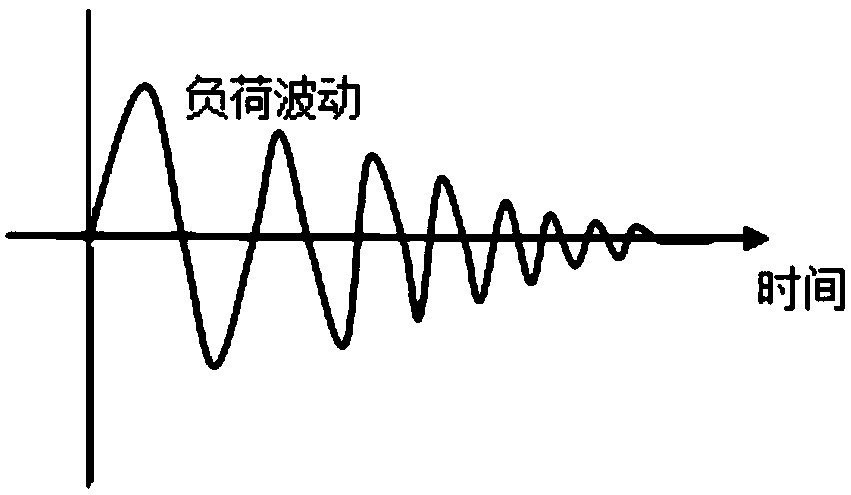

A cooling system and dewaxing technology, which is applied in the direction of energy-saving heating/cooling, refrigerators, petroleum industry, etc., can solve problems that affect product quality, fail to meet production requirements, consume transportation energy consumption, etc., and achieve the elimination of large temperature fluctuations and save Groundwater resources and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

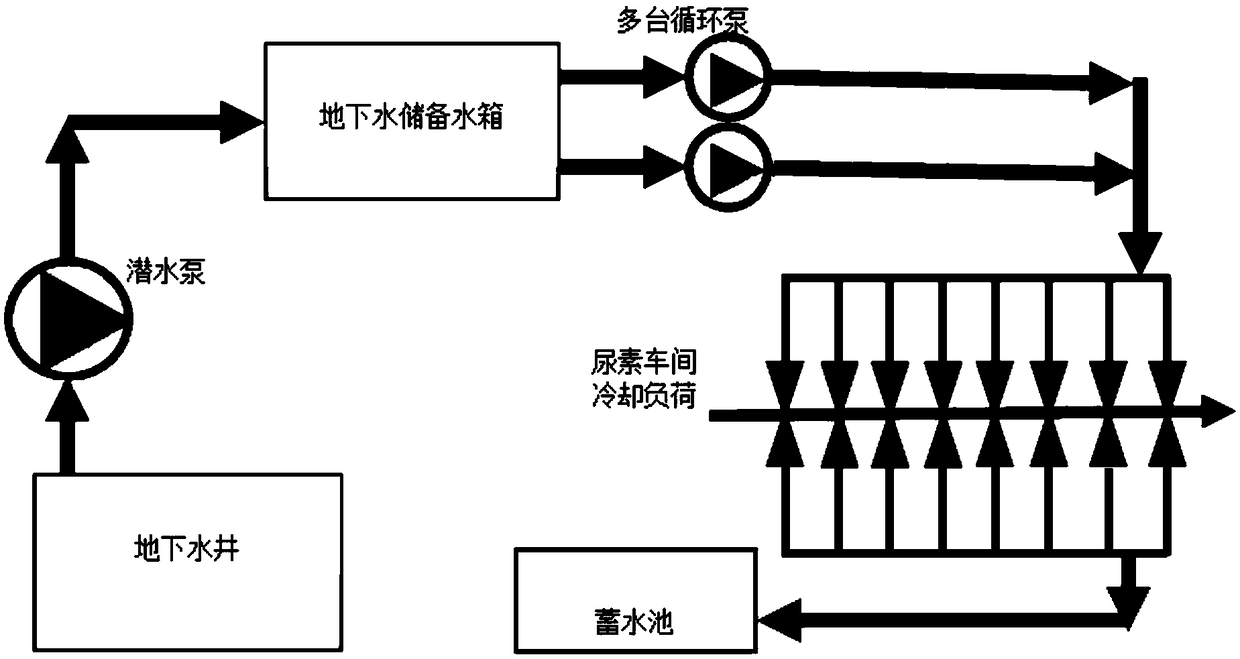

[0025] Such as figure 1 As shown, its traditional cooling system consists of underground water sources, submersible pumps, storage tanks, chilled water circulation pumps, and multiple sets of casing reactors. Submersible pumps pump groundwater from groundwater source wells and store it in groundwater storage tanks. Operate one or more circulating water pumps according to the temperature of the groundwater, and the pumped groundwater is sent to the shell side of multiple sets of casing reactors, and the raw material oil is mixed with urine and sent to the tube side of multiple sets of casing reactors, which is automatically adjusted by the amount of water inflow temperature.

[0026] figure 2 It is a flow chart of the cooling system applied in the urea dewaxing process of the present invention. It includes a lithium bromide absorption refrigerator unit, a main control system unit, a driving heat source control unit, and a sleeve reactor; the lithium bromide absorption refri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com