A photobiological reaction device that can effectively absorb and utilize exhaust gas

A photobioreaction and effective absorption technology, applied in photobioreactors, specific-purpose bioreactors/fermenters, biochemical cleaning devices, etc. Difficult to control the cultivation conditions and other problems, to achieve the effect of improving the photobiological reaction rate, promoting the circulation and flow of materials, and improving the utilization rate of light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

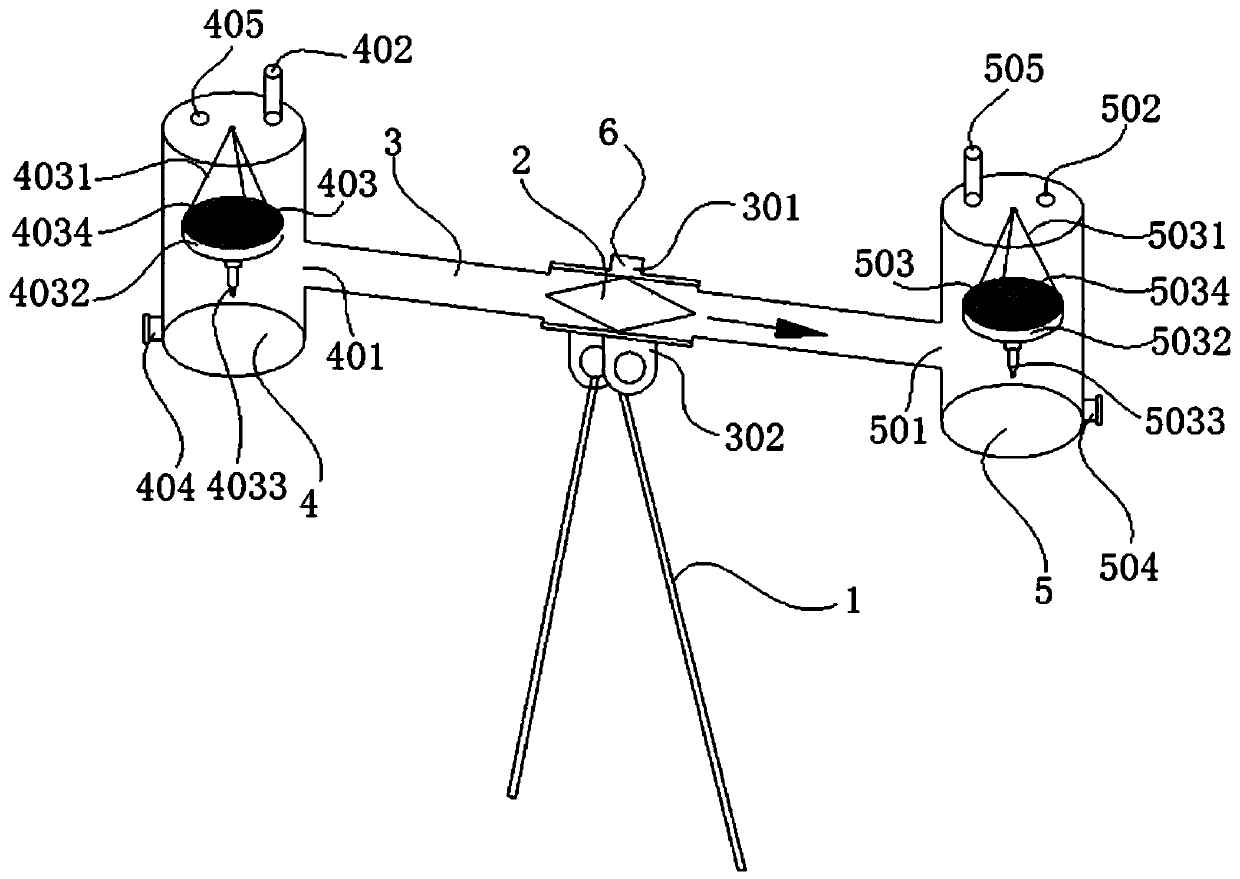

[0065] Such as figure 1 As shown, a photobioreaction device that can effectively absorb and utilize exhaust gas is characterized in that it mainly includes a support column 1, a flow plug 2, a hollow shaft 3, a transparent photobioreactor container A4 and a transparent photobioreactor container B5.

[0066] The hollow rotating shaft 3 is a tubular structure with both ends open and a hollow inside. The hollow rotating shaft 3 is a reducing pipe, the diameter of the hollow rotating shaft 3 in the middle is D, and the diameter of the pipes at both sides is d, where D>d.

[0067] When the hollow rotating shaft 3 is placed parallel to the ground, an opening 301 is provided at the top of the outer wall at the middle position of the hollow rotating shaft 3 , and a base 302 is provided at the bottom end of the outer wall at the middle position.

[0068] The hollow rotating shaft 3 is connected with the support column 1 through the base 302 . Both sides of the hollow rotating shaft 3...

Embodiment 2

[0106] Experiment using the device in Example 1;

[0107] A flue gas inlet valve 6 is arranged above the center of the hollow rotating shaft 3, and the exhaust gas discharged from the gas turbine or other smoke exhaust equipment during operation mainly includes CO 2 and H 2 O enters the hollow shaft 3 through the flue gas inlet valve 6;

[0108] When the hollow rotating shaft 3 is kept horizontal, the flow plug 2 is also kept horizontal and does not block any channel opening at either end of the hollow rotating shaft 3, and the exhaust gas can smoothly enter the transparent photobioreaction container A4 connected to the two ends of the hollow rotating shaft 3 through the channel openings on both sides And in the transparent photobioreactor container B5, in the horizontal reactor I403 and the horizontal reactor II503 in the transparent photobioreactor container A4 and the transparent photobioreactor B5, there are photoreactive organisms I4034 and photoreactive biological II503...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com