Copper alloy material and preparation method thereof

A copper alloy and aging heat treatment technology, applied in the field of copper alloy smelting and processing, can solve problems such as the inability to achieve the best performance of copper-silver alloy materials, and achieve the effects of eliminating structural defects, stable performance and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the copper-silver alloy material of the present embodiment may further comprise the steps:

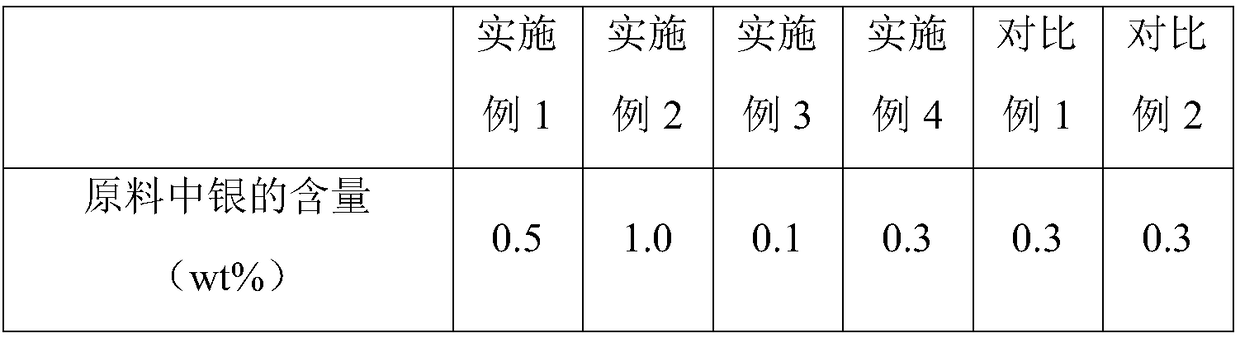

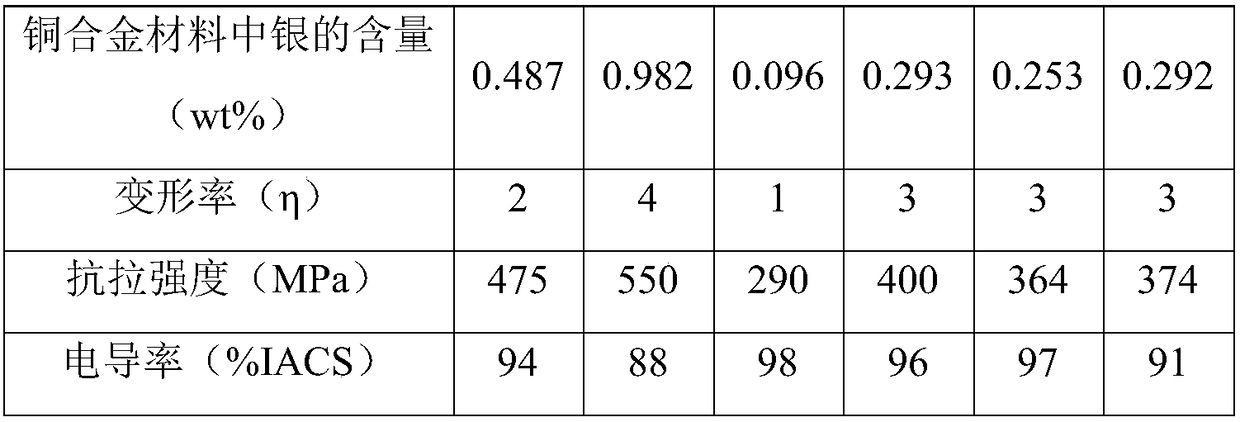

[0031] 1) Take oxygen-free copper, silver particles with a purity of 99.9% and a diameter of 0.5 cm as raw materials, and carry out ingredients according to the proportion of silver being 0.5 wt % and the balance being copper;

[0032] 2) Vacuum smelting technology is used to prepare ingots, and the copper and silver with a good ratio are put into the vacuum smelting furnace at one time without mixing, and the silver particles are put into the storage room, and then vacuumized. When the vacuum degree reaches 9.0× 10 -3 Start heating at Pa, increase the power, and when the temperature reaches 900°C, turn off the vacuum and fill it with argon until the vacuum degree is 1.0×10 2 Pa, when the temperature reaches 1150°C, silver is added and stirred. After stirring for 2-3 minutes, it is cast and cooled naturally to obtain an ingot.

[0033] 3) The temperat...

Embodiment 2

[0037] The preparation method of the high-strength copper-silver alloy material of the present embodiment comprises the following steps:

[0038] 1) Use oxygen-free copper, silver particles with a purity of 99.9% and a diameter of 0.01 cm as raw materials, and carry out ingredients according to the proportion of silver being 1.0 wt % and the balance being copper;

[0039] 2) Prepare copper-silver alloy bars by using vacuum smelting technology. Put copper and silver with a good ratio into the vacuum smelting furnace at one time but do not mix them. The silver particles are put into the storage room, and then vacuumized. When the vacuum degree up to 9.0×10 -3 Start heating at Pa, increase the power, turn off the vacuum when the temperature reaches 800°C, and fill it with argon until the vacuum degree is 1.0×10 2 Pa, when the temperature reaches 1200°C, silver is added and stirred for 2-3 minutes, then cast and cooled to obtain an ingot.

[0040] 3) The solution treatment tempe...

Embodiment 3

[0044] The preparation method of the high-strength copper-silver alloy material of the present embodiment comprises the following steps:

[0045] 1) With oxygen-free copper and silver particles with a purity of 99.9% and a diameter of 0.05 cm as raw materials, the proportion of silver is 0.1 wt%, and the balance is copper;

[0046] 2) Prepare copper-silver alloy bars by using vacuum smelting technology. Put copper and silver with a good ratio into the vacuum smelting furnace at one time but do not mix them. The silver particles are put into the storage room, and then vacuumized. When the vacuum degree up to 9.0×10-3 Start heating at Pa, increase the power, turn off the vacuum when the temperature reaches 850°C, and fill it with argon until the vacuum degree is 1.0×10 2 Pa, when the temperature reaches 1180°C, silver is added and stirred for 2-3 minutes before casting and cooling to obtain an ingot.

[0047] 3) The temperature of the solution treatment for the ingot is 800°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com