A method for characterizing strengthening phases of ferromagnetic alloy bulk and/or thin films

A technology of strengthening phases and alloy blocks, which is applied in the direction of material analysis, instruments, and measuring devices using wave/particle radiation, which can solve the problems of expensive, increasing difficulty and cost of ferromagnetic alloy analysis and characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

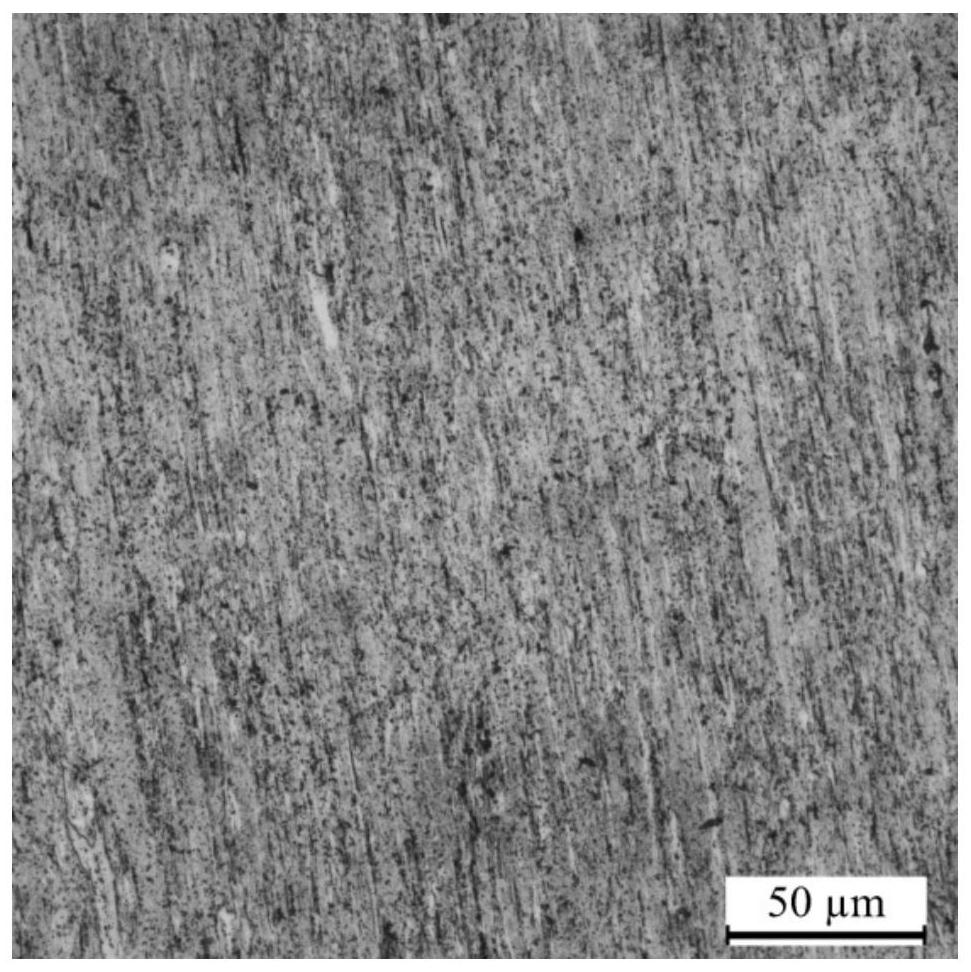

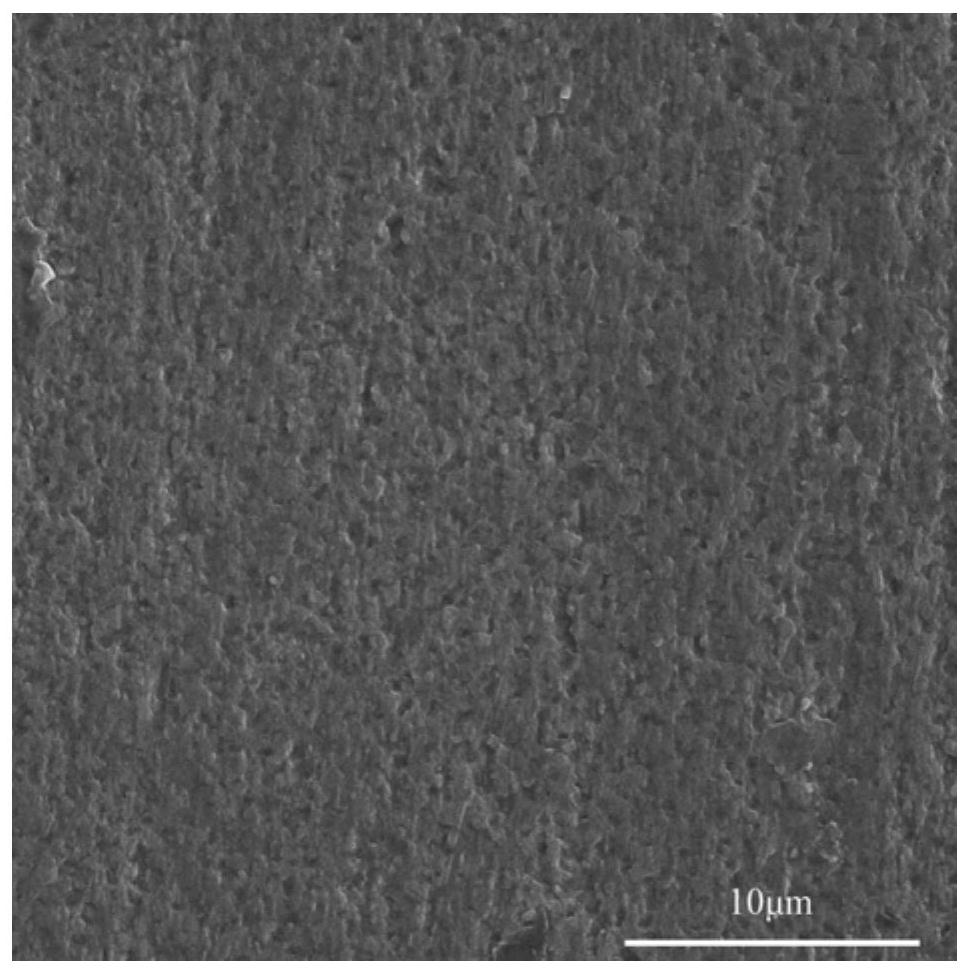

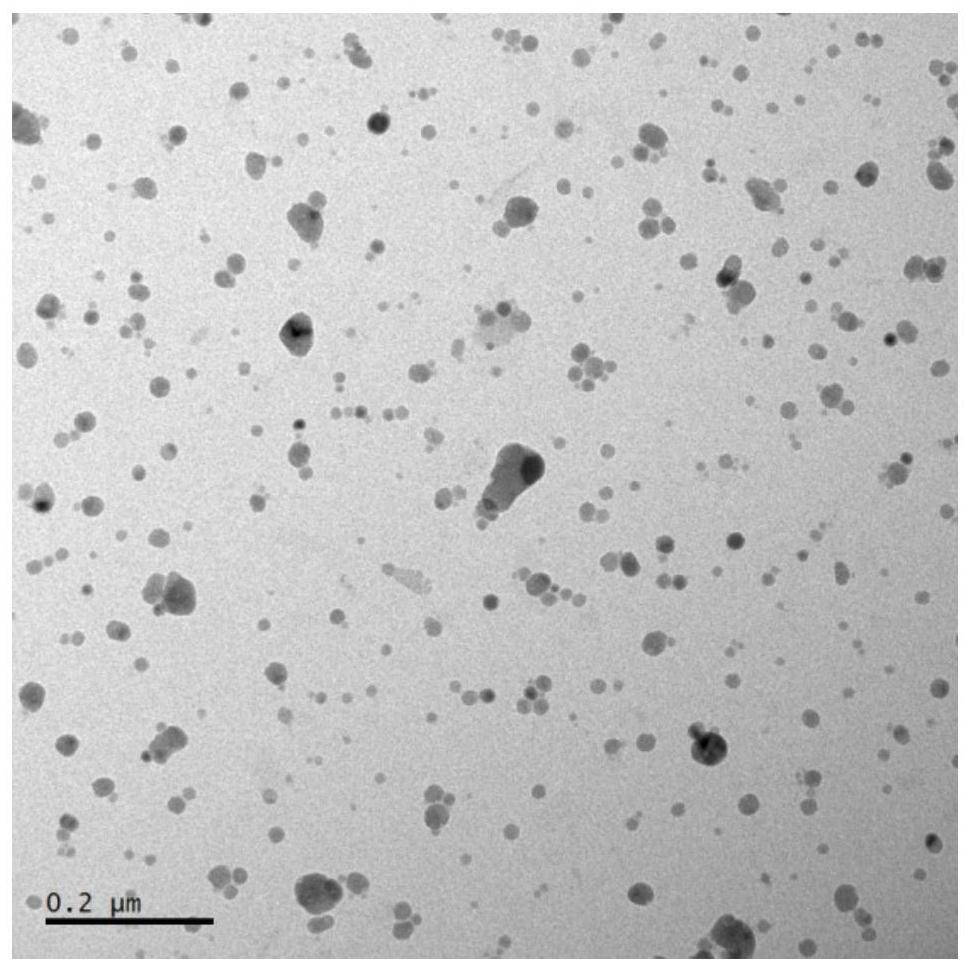

[0059] Embodiment 1: Fe-14Cr-3W-0.4Ti-1.0Y 2 o 3 (wt.%)Characterization of alloy strengthening phase

[0060] In the electrolytic separation of Fe-14Cr-3W-0.4Ti-1.0Y 2 o 3 (wt.%) Before the alloy strengthening phase, the microstructure of the alloy was characterized by OM. Then carry out electron microscope characterization according to the following steps:

[0061] The first step: using Fe-14Cr-3W-0.4Ti-1.0Y 2 O (wt.%) 3 The alloy sample is used as the anode, the stainless steel cylinder is used as the cathode, electrolyzed in the electrolyte, Fe-14Cr-3W-0.4Ti-1.0Y 2 o 3 (wt.%) The strengthening phase in the alloy is separated from the alloy matrix to obtain an electrolyte solution containing the strengthening phase. The electrolyte used is composed of 2% of tetramethylammonium chloride, 15% of acetylacetone, 3% of glycerol, and the balance is absolute ethanol. The electrolysis parameters are: voltage 6V, electrolysis time 10min;

[0062] The second step is to extra...

Embodiment 2

[0067] Embodiment 2: Fe-14Cr-3W-0.4Ti-0.25Y 2 o 3 (wt.%)Characterization of alloy strengthening phase

[0068] In the electrolytic separation of Fe-14Cr-3W-0.4Ti-0.25Y 2 o 3 (wt.%) Before the alloy strengthening phase, the microstructure of the alloy was characterized by OM. Then carry out electron microscope characterization according to the following steps:

[0069] The first step: using Fe-14Cr-3W-0.4Ti-0.25Y 2 o 3 (wt.%) The alloy sample is used as the anode, the stainless steel cylinder is used as the cathode, and electrolyzed in the electrolyte, the Fe-14Cr-3W-0.4Ti-0.25Y 2 o 3 (wt.%) The strengthening phase in the alloy is separated from the alloy matrix to obtain an electrolyte solution containing the strengthening phase. The electrolyte solution used is composed of: 2% tetramethylammonium chloride, 3% cetyltrimethylammonium chloride, 25% acetylacetone, 5% glycerol, and the balance is absolute ethanol. The electrolysis parameters are: voltage 3V, electrolysis ...

Embodiment 3

[0075] Embodiment 3: Fe-14Cr-3W-0.4Ti-5Y 2 o 3 (wt.%)Characterization of alloy strengthening phase

[0076] In the electrolytic separation of Fe-14Cr-3W-0.4Ti-5Y 2 o 3 (wt.%) Before the alloy strengthening phase, the microstructure of the alloy was characterized by OM. Then carry out electron microscope characterization according to the following steps:

[0077] The first step: using Fe-14Cr-3W-0.4Ti-5Y 2 o 3 (wt.%) The alloy sample is used as the anode, the stainless steel cylinder is used as the cathode, and electrolyzed in the electrolyte, the Fe-14Cr-3W-0.4Ti-5Y 2 o 3 (wt.%) The strengthening phase in the alloy is separated from the alloy matrix to obtain an electrolyte solution containing the strengthening phase. The electrolytic solution used is composed of: 0.5% tetramethylammonium chloride, 5% acetylacetone, and the balance is anhydrous methanol. The electrolysis parameters are: voltage 3V, electrolysis 4h.

[0078] In the second step, the electrolyte solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size distribution | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com