Multi-layer net shaped staggered rib plate type hydrogen storage reaction device

The technology of a reaction device and a rib plate is applied in the direction of tubular elements, heat exchange equipment, fixed tubular conduit components, etc., and can solve the problems of inability to promote large-scale industrial applications, complicated processing technology of heat exchangers, and inability to popularize and use in large quantities. Achieve the effect of compact structure, small gas phase diffusion resistance and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

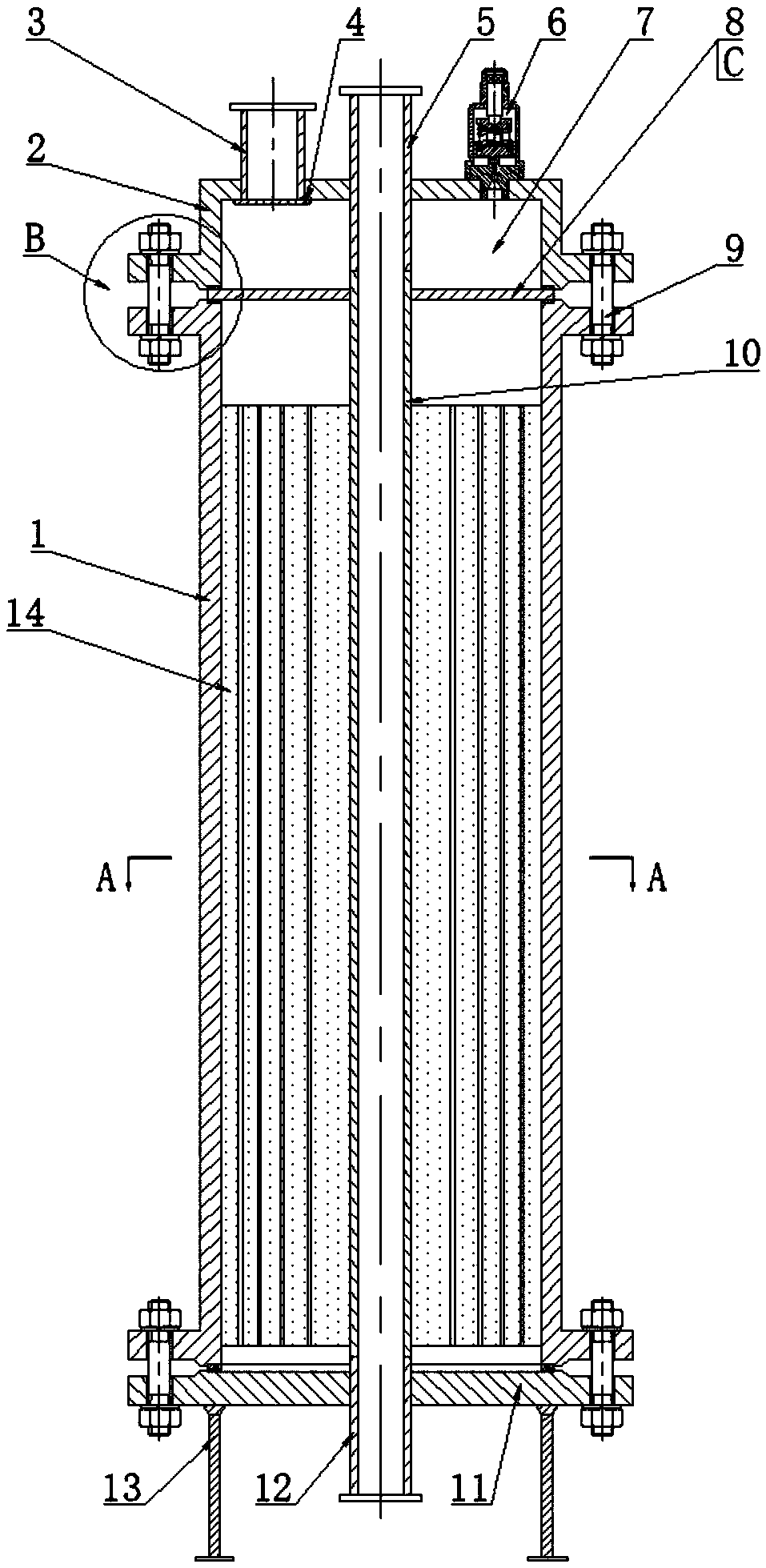

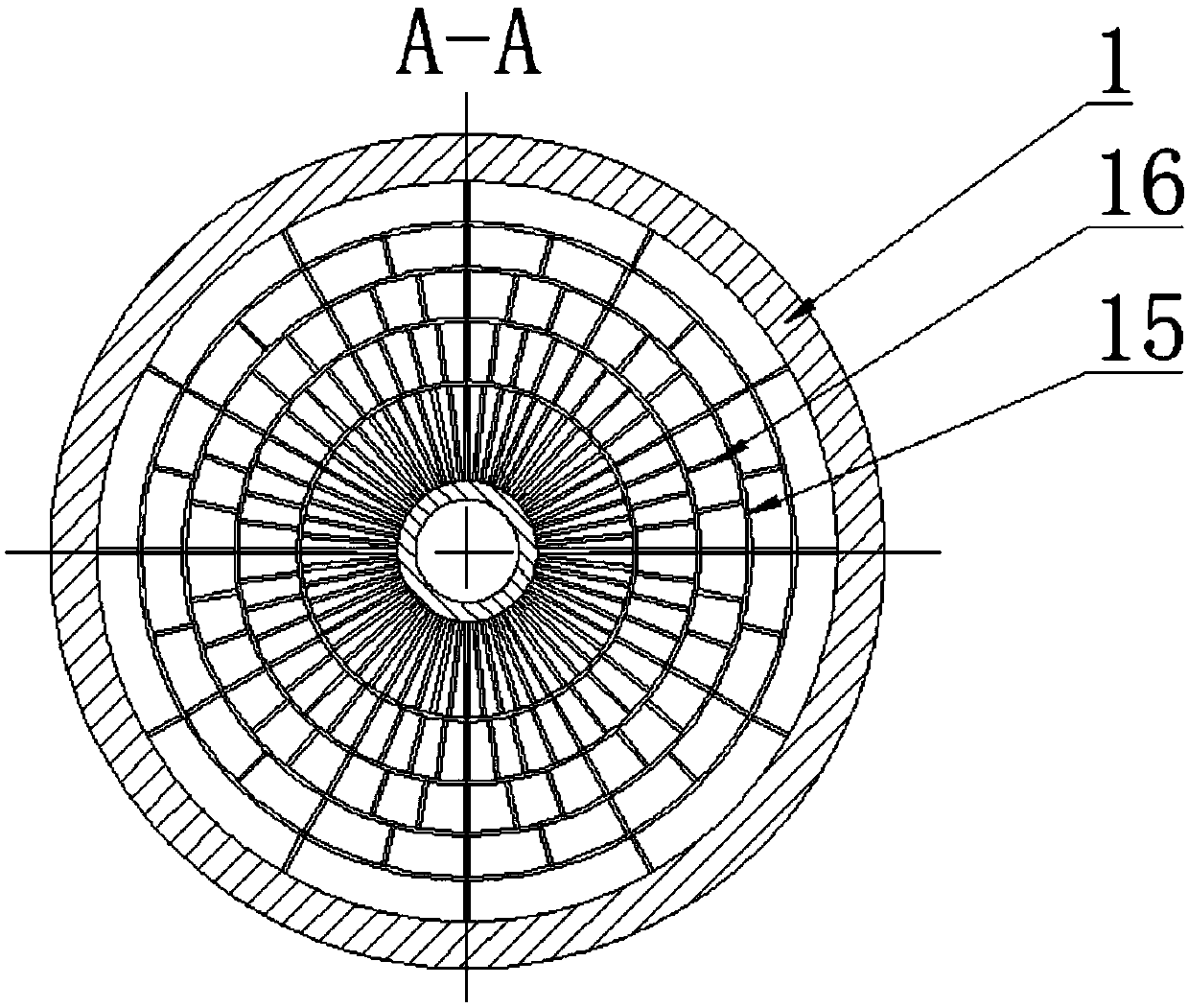

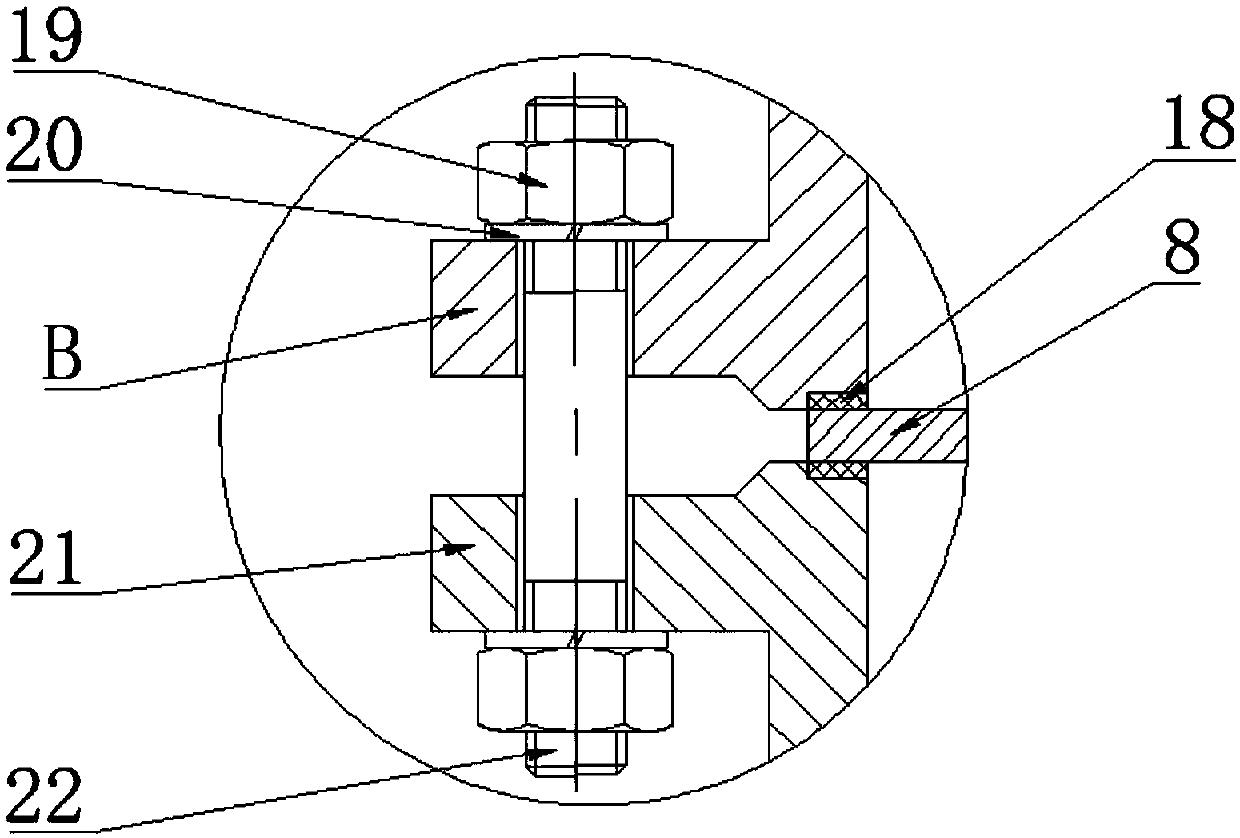

[0033] The invention provides a hydrogen storage reaction device with multi-layer mesh interlaced ribs, the device is a vertical structure, such as figure 1 As shown, the housing 1 is included, and the upper and lower ends of the housing 1 are respectively sealed and connected with an upper head 2 and a lower head 11 through a flange structure 9 . Wherein, a heat exchange tube 10 is arranged at the center of the housing 1, and multi-layer circumferential ribs 15 are sequentially arranged between the inner wall of the housing 1 with the heat exchange tube 10 as the center, and the heat exchange tube 10 and the housing are connected. 1 The space between the inner walls is divided into a plurality of reaction areas, and the area of each reaction area is equal, and a reaction vehicle layer 14 is arranged in the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com