Mepiquat chloride-containing controlled release urea special for cotton and preparation method thereof

A technology for controlled release of urea and mepamine, which is applied in urea compound fertilizers, applications, organic fertilizers, etc., can solve the problems of poor pertinence of controlled release urea, improve nitrogen utilization rate, improve stress resistance and survival rate, The effect of reducing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In the embodiment of the present invention, a kind of controlled-release urea for cotton containing benzedramine uses urea particles and benzedramine as the core material, and epoxy resin and curing agent as the outer coating material. The urea particles include urea and auxiliary Materials Borax, polyaspartic acid and potassium fulvic acid.

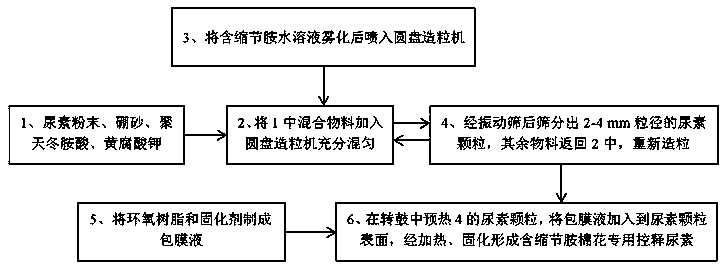

[0021] The present invention provides the preparation method of the cotton-specific controlled-release urea containing benzyl amine, comprising the following steps:

[0022] (1) Pass 19kg of urea, 0.2kg of borax, 0.4kg of polyaspartic acid, and 0.4kg of potassium fulvic acid through a 60-mesh sieve. 5%, place the sieved urea, borax, polyaspartic acid, and potassium fulvic acid in a disc granulator, fully mix the materials evenly at a speed of 20 rpm, and obtain the mixed materials;

[0023] (2) Dissolve 100 g of benzedramine into 1900 ml of distilled water to make an aqueous solution containing 5% of benzedramine, use this as a b...

Embodiment 2

[0028] In the embodiment of the present invention, a kind of controlled-release urea for cotton containing benzedramine uses urea particles and benzedramine as the core material, and epoxy resin and curing agent as the outer coating material. The urea particles include urea and auxiliary Materials Borax, polyaspartic acid and potassium fulvic acid.

[0029] The present invention provides the preparation method of the cotton-specific controlled-release urea containing benzyl amine, comprising the following steps:

[0030] (1) Pass 18 kg of urea, 0.5 kg of borax, 0.7 kg of polyaspartic acid, and 0.8 kg of potassium fulvic acid through a 60-mesh sieve, and the auxiliary materials borax, polyaspartic acid, and fulvic acid account for 10% of the weight ratio of the materials. %, place the sieved urea, borax, polyaspartic acid, and potassium fulvic acid in a disc granulator, and fully mix the uniform material at a speed of 20 rpm to obtain a mixed material;

[0031] (2) Dissolve 15...

Embodiment 3

[0036] In the embodiment of the present invention, a kind of controlled-release urea for cotton containing benzedramine uses urea particles and benzedramine as the core material, and epoxy resin and curing agent as the outer coating material. The urea particles include urea and auxiliary Materials Borax, polyaspartic acid and potassium fulvic acid;

[0037] The present invention provides the preparation method of the cotton-specific controlled-release urea containing benzyl amine, comprising the following steps:

[0038] (1) Pass 17.4 kg urea, 0.8 kg borax, 0.8 kg polyaspartic acid, and 1 kg potassium fulvic acid through a 60-mesh sieve, and the auxiliary materials borax, polyaspartic acid, and potassium fulvic acid account for 13%, urea after sieving, borax, polyaspartic acid, potassium fulvic acid are placed in the disc granulator, fully mix the homogeneous material with the rotating speed of 20 rpm, obtain the mixed material;

[0039] (2) Dissolve 180 g of benzyl amine int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com