Polypropylene material with high rigidity and high heat resistance and preparation method thereof, as well as injection molding product and preparation method thereof

A polypropylene material, injection molding technology, applied in the field of polypropylene material and its preparation, can solve the problems of increased cost, setting to 240 ℃-245 ℃, etc., and achieves improved strength and heat resistance temperature, low defect rate, powder filling high volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

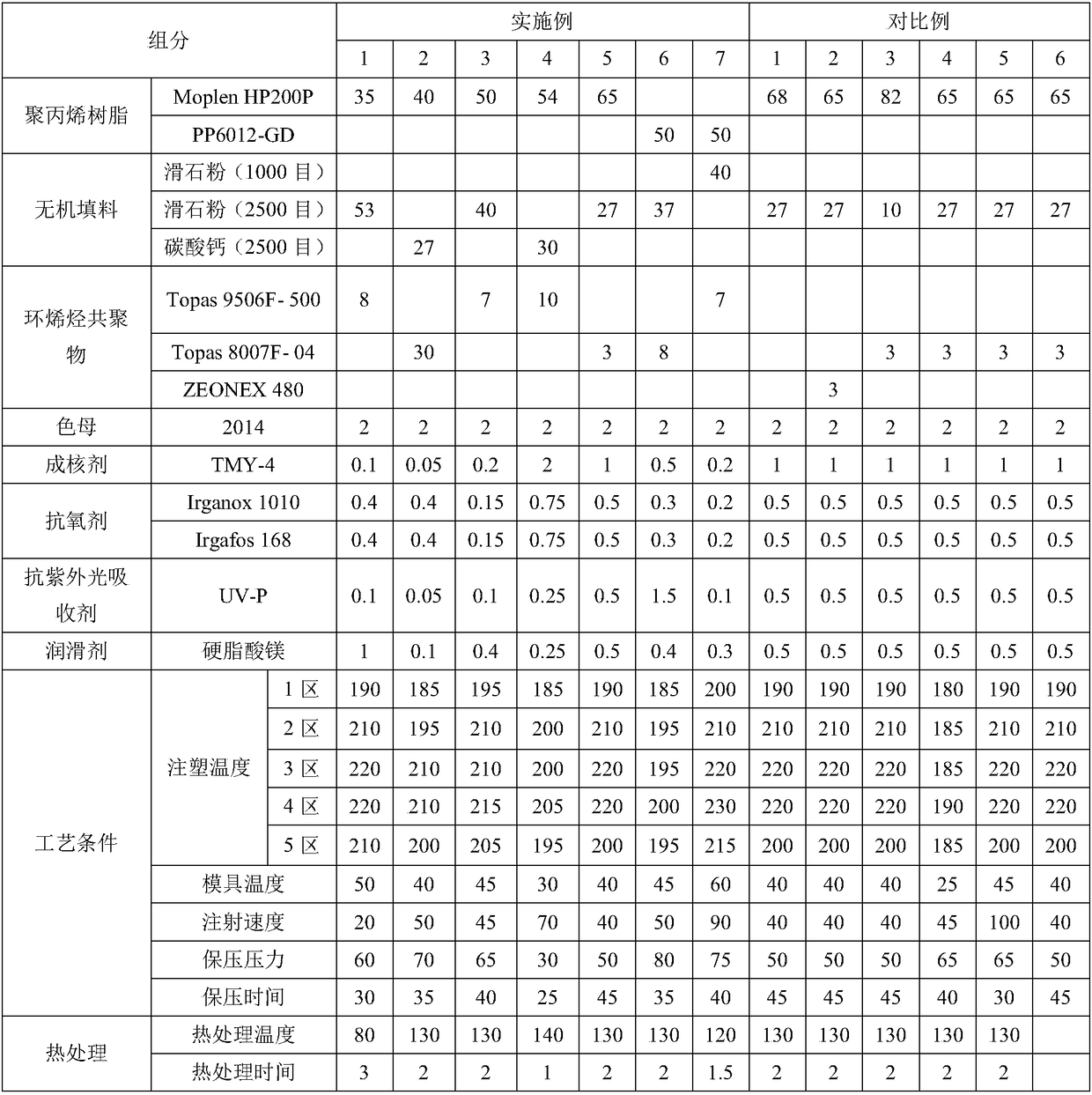

[0039] Combine 35wt% polypropylene Moplen HP200P, 8wt% cycloolefin polymer Topas 9506F-04, 2wt% masterbatch 2014, 0.1wt% nucleating agent TMY-4, 0.4wt% primary antioxidant Irganox 1010 , 0.4wt% of the auxiliary antioxidant Irgafos 168, 0.1wt% of the anti-ultraviolet absorber UV-P, 1wt% of magnesium stearate mixed in a high-mixer for 10 minutes and then added to the 35mm diameter ratio of 52 In the main feed port of the twin-screw extruder, 53wt% of 2500 mesh talc powder is added to the side feed port. The temperature of the 13 zone of the twin-screw extruder is set to 195℃, 205℃, 205℃, 210℃, 210℃. , 210°C, 215°C, 215°C, 215°C, 215°C, 205°C, 205°C, 195°C, mixing and granulating under the conditions of rotating speed 250rpm.

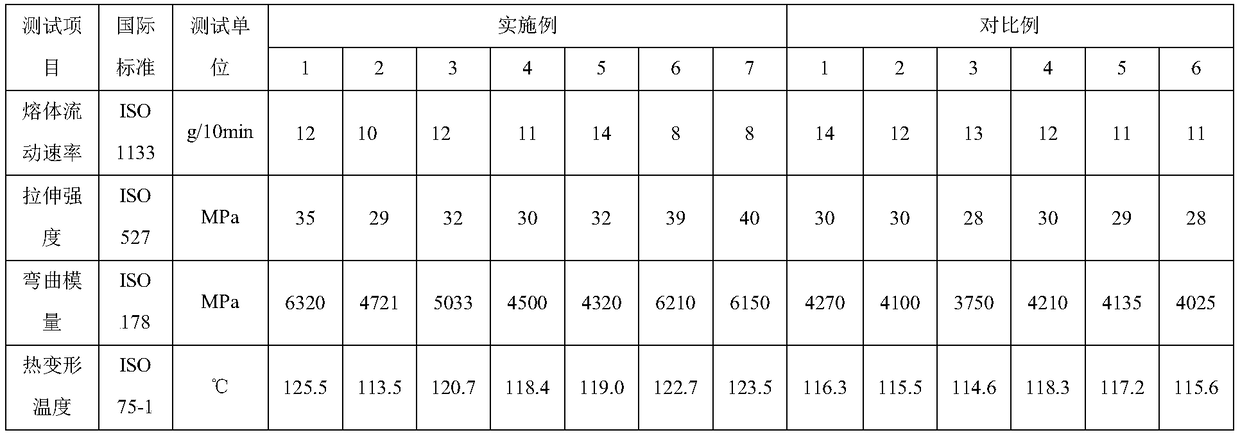

[0040] Performance evaluation methods and implementation standards:

[0041] The particle material granulated according to the above method is first dried in a blast oven at 100°C for 2 hours, and then the dried particle material is injection molded on a 90t i...

Embodiment 2-7

[0046] The formula and injection molding process conditions are shown in Table 1, and the other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com