Composition and application for resisting oxygen resistance and improving surface curing degree of photocurable ink

A light-curing ink and surface curing technology, which can be used in inks, applications, household appliances, etc., can solve the problems of UV-curable ink surface drying speed and surface performance limitations, coating bottom layer curing, surface uncured, etc., to achieve excellent photosensitivity Improvement of sex, photosensitivity, and improvement of surface film retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

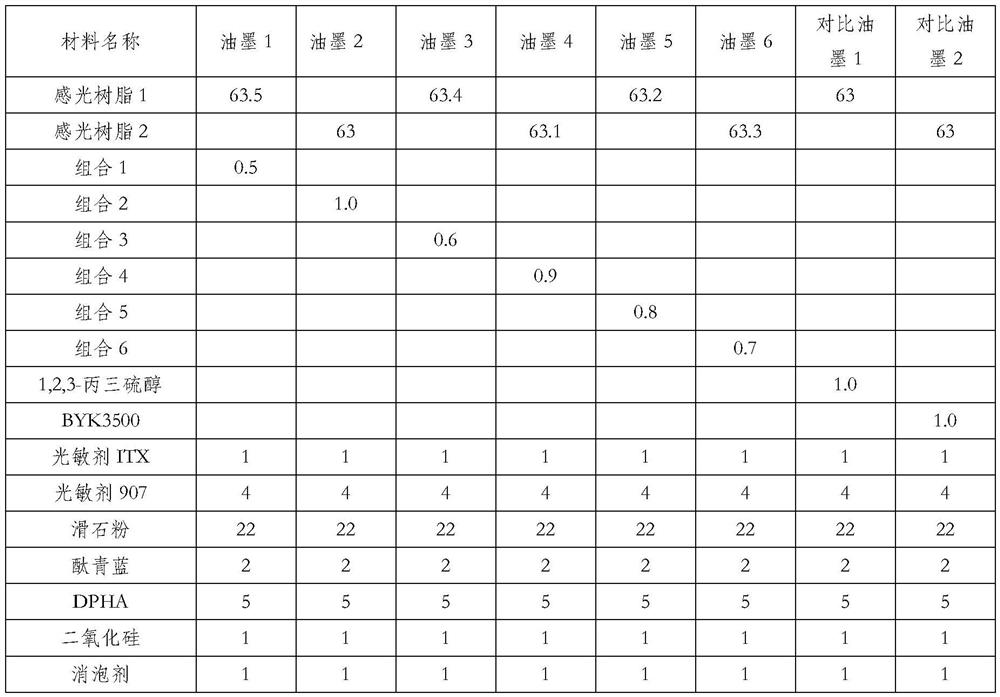

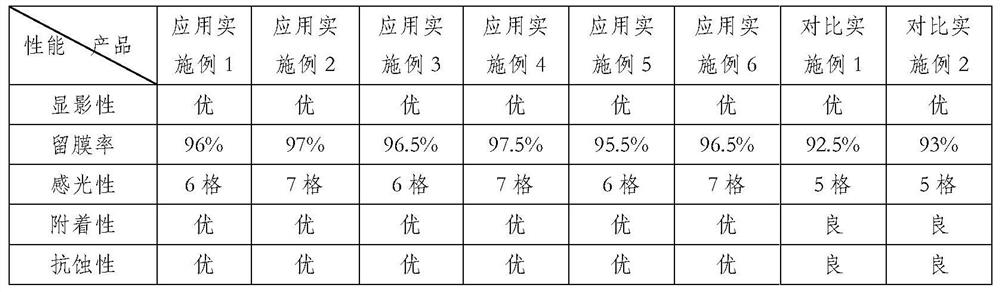

Examples

Embodiment

[0071] Resin Synthesis Example

[0072] Synthetic Example 1 (photosensitive resin 1)

[0073] In the reactor, add 200g novolac epoxy resin CNE-202 (Taiwan Changchun Life Resin Factory, epoxy equivalent 210), 250g propylene glycol methyl ether acetate (PMA), 69g acrylic acid, heat and melt, then add 0.5g p-phenylene Diphenol and 1.5 g of triphenylphosphine were reacted at 110° C. for 12 hours to obtain a product with an acid value of less than 5. Then add 85g of tetrahydrophthalic anhydride, heat to 100°C, and react for 6 hours to obtain light yellow resin solution A1 (photosensitive resin 1), with an acid value of 52mgKOH / g, a solid content of 59%, and a Mw of about 2000 .

[0074] Synthetic Example 2 (photosensitive resin 2)

[0075] Add methyl methacrylate, butyl methacrylate and acrylic acid in the reactor according to the molar ratio of 1:1:2, use carbitol acetate as the solvent, and use azobisisobutyronitrile (AIBN) as the catalyst , stirred at 80° C. for 4 hours to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com