Catalyst for synthesizing 2-cyanopyrazine and preparation and application methods thereof

A technology of cyanopyrazine and catalyst, applied in the field of synthesizing 2-cyanopyrazine, achieving the effects of simple preparation method, good catalytic effect, and convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

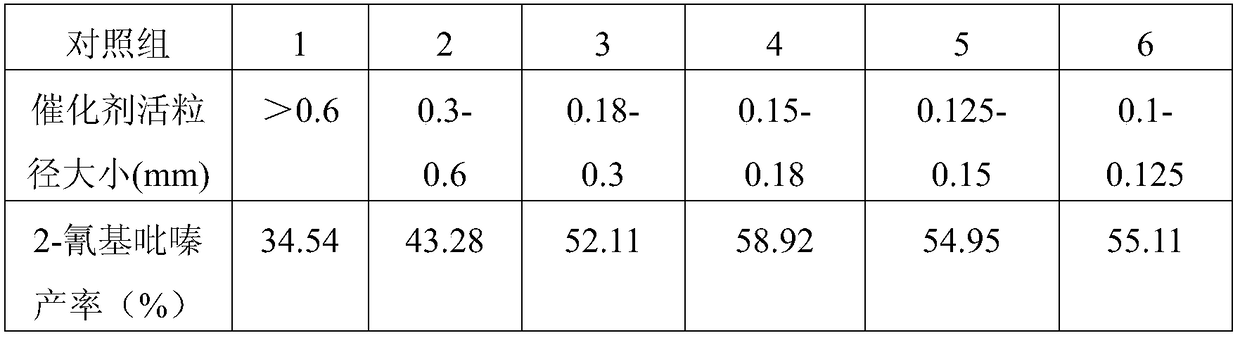

Examples

Embodiment

[0039] A preparation method for synthesizing 2-cyanopyrazine catalyst, it comprises the following sequential steps:

[0040] Step 1. Burn γ-Al in a crucible with a resistance furnace at a temperature of 550°C 2 o 3 , and the firing time is 6h to obtain a catalytic carrier, which is stored in a dry bottle for use;

[0041] Step 2. Weigh 2.70g of oxalic acid solid into a 100ml beaker, add 35ml of distilled water to dissolve;

[0042] Step 3. Weigh 0.281g V 2 o 5 And add oxalic acid solution to dissolve;

[0043] Step 4. Weigh 0.250g CrO 3 Add to the above solution and stir for 2-3 minutes;

[0044] Step 5. Use a pipette to pipette 0.275ml H 3 PO 4 In the above mixture, stir for 1 minute;

[0045] Step 6. Transfer the above solution to a 500ml three-necked flask, fix it in a constant speed stirrer, and stir at a constant temperature of 60°C for 10 minutes;

[0046] Step 7. Transfer the fully reacted solution to a 100ml beaker and cool to room temperature. (the solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com