Supported catalyst as well as preparation method and application thereof

A supported catalyst and catalyst technology, which are applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low efficiency, cumbersome preparation of supported catalysts, poor stability, etc., and simplify the preparation. method, good electrocatalytic performance, and the effect of controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The preparation method of the supported catalyst of the present embodiment comprises the following steps:

[0059] 1) Put 10g Ti 3 AlC 2 Soak in 100 mL of hydrofluoric acid for 12 h to remove Al element, then centrifuge, wash the obtained solid with distilled water for several times, and dry to obtain multilayer Ti 3 C 2 T x powder;

[0060] 2) The obtained multilayer Ti 3 C 2 T x The powder was immersed in dimethyl sulfoxide for 24 hours, and then centrifuged. After washing the obtained solid for many times, it was dispersed in 200 mL of distilled water, and then placed in an ultrasonic cell disintegrator for ultrasonic peeling for 4 hours, centrifuged for 30 minutes, and freeze-dried to obtain black ti 3 C 2 T x Nanosheets;

[0061] 3) Transfer 1800 μL of ethylene glycol into a 4.0 mL glass vial, and then add 2 mg of the obtained Ti 3 C 2 T x The nanosheets were uniformly dispersed by ultrasonic treatment for 15 minutes to obtain a carrier dispersion;

...

Embodiment 2

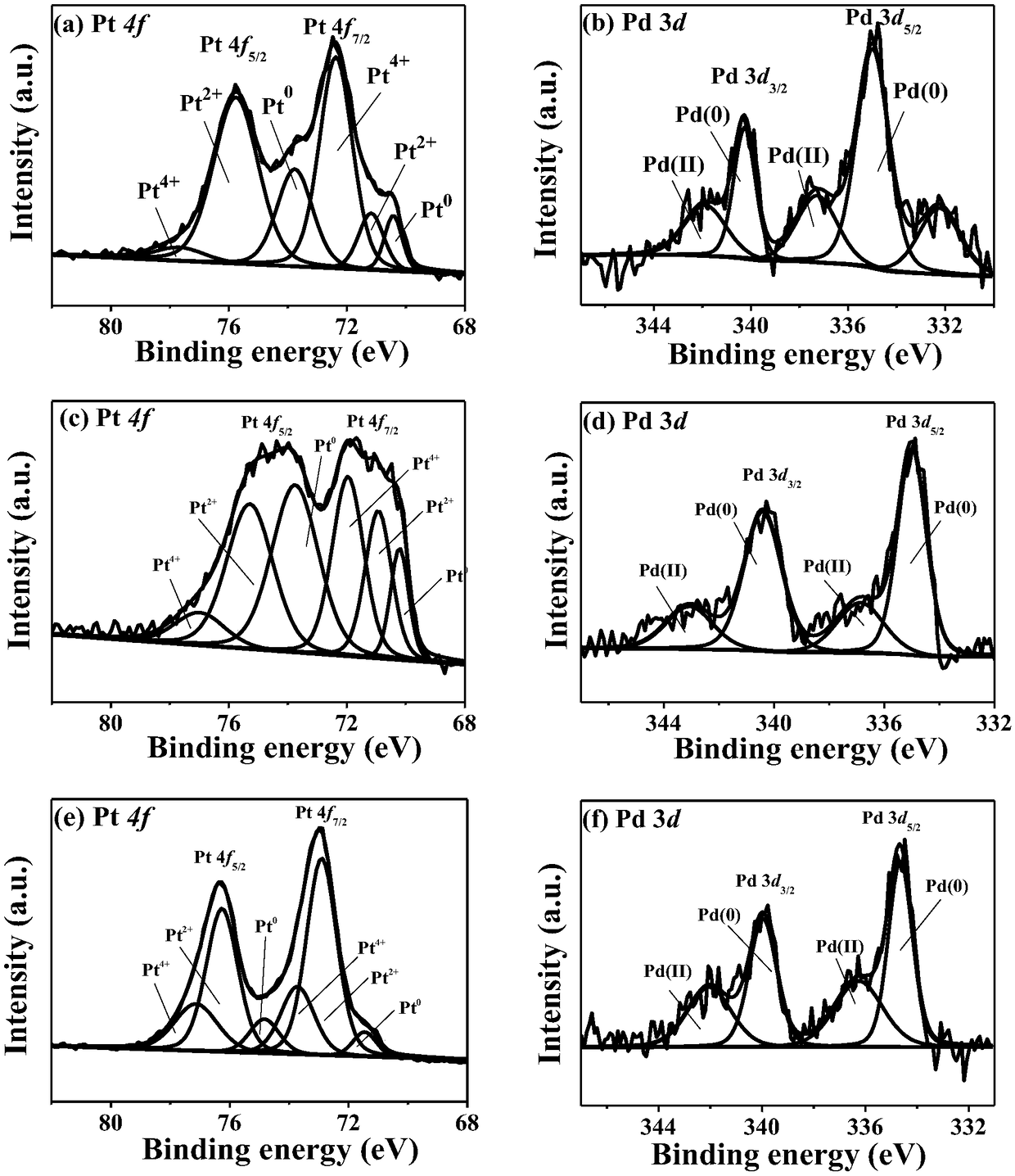

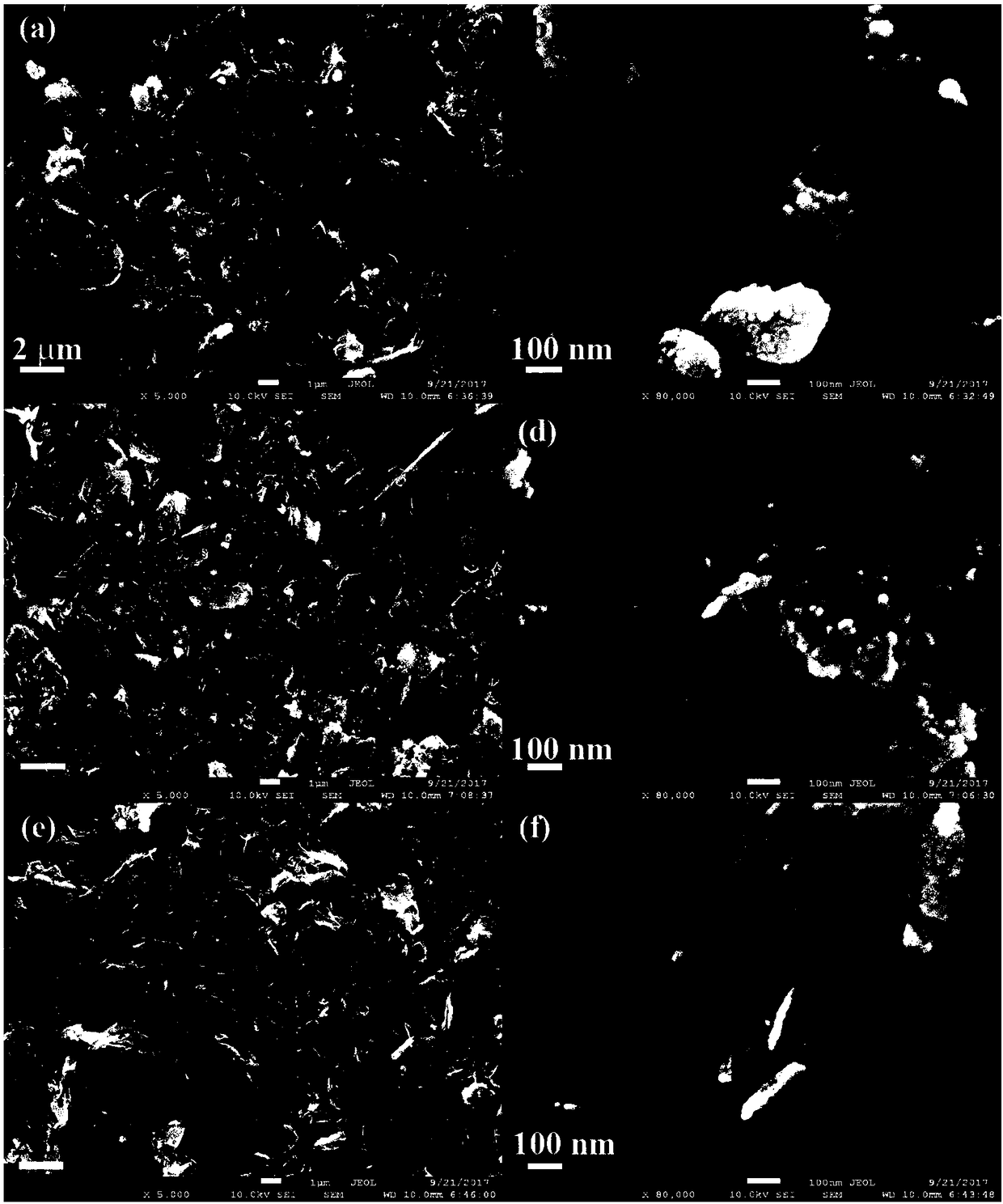

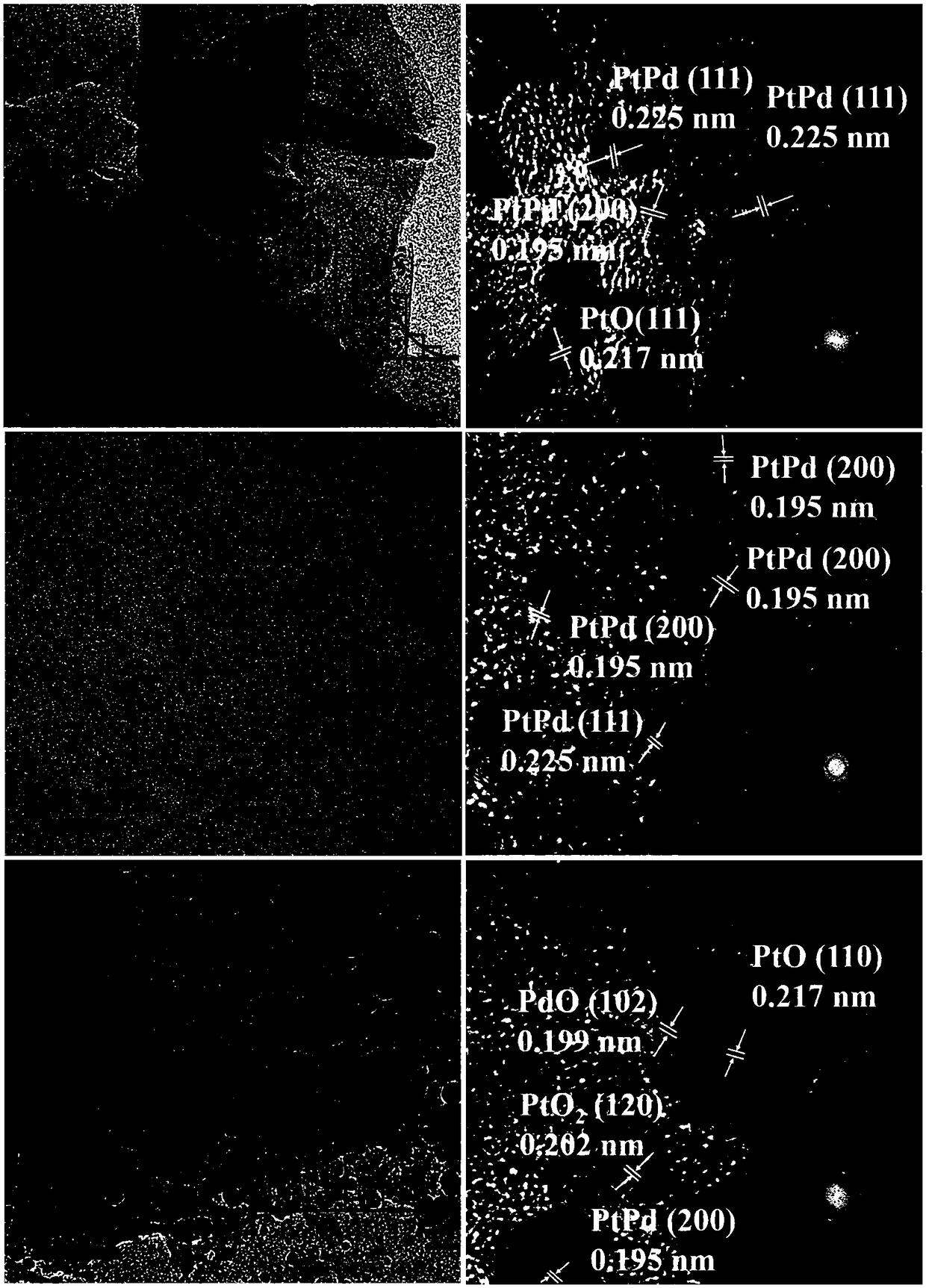

[0067] The difference between the preparation method of the supported catalyst in this example and the preparation method of Example 1 is only that in step 5), the plasma irradiation treatment time is 3 minutes;

[0068] The supported catalyst prepared in this example is also denoted as PtO a PdO b NPs@Ti 3 C 2 T x . The suspension prepared in this example was stored at 4°C for further electrochemical measurements.

[0069] The supported catalyst of this embodiment is prepared by the preparation method of this embodiment.

Embodiment 3

[0071] The difference between the preparation method of the supported catalyst in this example and the preparation method of Example 1 is only that in step 5), the time of plasma irradiation treatment is 5 minutes;

[0072] The supported catalyst prepared in this example is also denoted as PtO a PdO b NPs@Ti 3 C 2 T x . The suspension prepared in this example was stored at 4°C for further electrochemical measurements.

[0073] The supported catalyst of this embodiment is prepared by the preparation method of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com