Environment-friendly biological hydroxymethyl cellulose photocatalytic composite membrane as well as preparation method and application thereof

A technology of hydroxymethyl cellulose and biological hydroxymethyl, applied in the field of hydroxymethyl cellulose photocatalytic composite membrane materials, can solve the problems of low catalytic efficiency, non-reusable, complicated methods, etc., and achieve high photocatalytic degradation rate , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

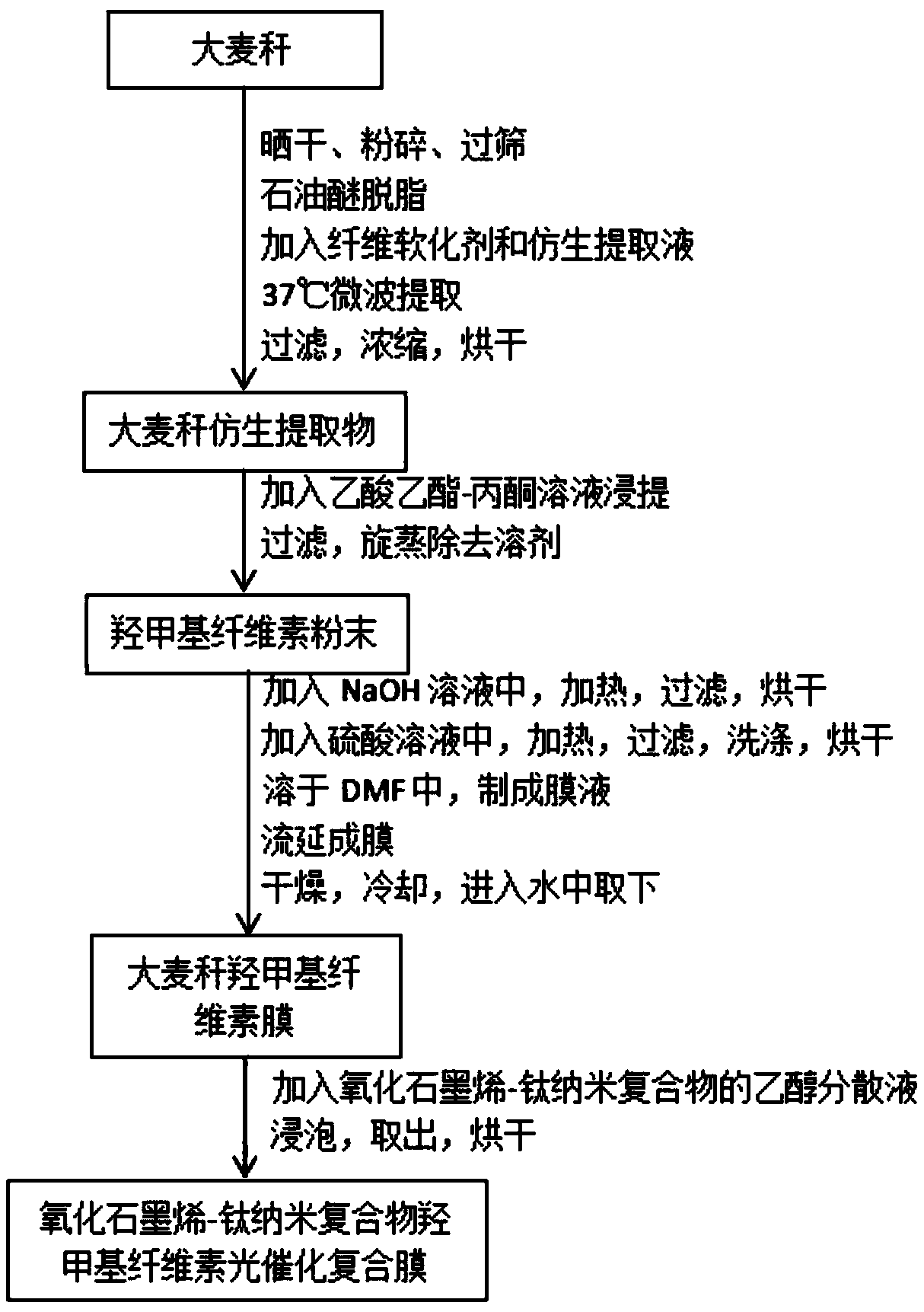

[0031] Example 1 Preparation of Environmentally Friendly Biological Hydroxymethyl Cellulose Photocatalytic Composite Membrane

[0032] Follow the steps below:

[0033] (1) Ultrasonic-assisted biomimetic extraction of barley straw: dry and crush the barley straw, pass through a 100-mesh sieve, add 10 times the weight of petroleum ether to degrease, and filter under reduced pressure. Mix barley straw powder, fiber softener, and bionic extract at a weight ratio of 1:10:20, heat in a water bath at 37°C, seal with a plastic film, and extract with microwaves. The microwave frequency is 2200MHz, the microwave power is 400W, and the extraction time is 40min. Filtrate with suction, collect the filtrate, concentrate in a water bath to 1 / 4 volume, collect the concentrate, and dry at 100°C to obtain hydroxymethylcellulose powder with a yield of 65%;

[0034] (2) Extraction of hydroxymethyl cellulose: take the barley straw biomimetic extract prepared in step (1), add ethyl acetate-acetone...

Embodiment 2

[0039] Example 2 Preparation of Environmentally Friendly Biological Hydroxymethyl Cellulose Photocatalytic Composite Membrane

[0040] Follow the steps below:

[0041] (1) Extraction of hydroxymethyl cellulose from barley straw: dry the barley straw, crush it, pass through a 100-mesh sieve, add 10 times the weight of petroleum ether to degrease, and filter under reduced pressure. Mix barley straw powder, fiber softener, and bionic extract at a weight ratio of 1:20:40, heat in a water bath at 37°C, seal with a plastic film, and extract with microwaves. The microwave frequency is 2700MHz, the microwave power is 500W, and the extraction time is 60 minutes. Filtrate with suction, collect the filtrate, concentrate in a water bath to 1 / 4 volume, collect the concentrate, and dry at 100°C to obtain hydroxymethylcellulose powder with a yield of 92%;

[0042] (2) Extraction of hydroxymethyl cellulose: take the barley straw biomimetic extract prepared in step (1), add ethyl acetate-acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com