Method for separating diamond mixture

A mixture and diamond technology, which is applied in the field of separation and purification of diamond mixture, can solve environmental pollution and other problems, and achieve the effects of high extraction efficiency, good economic benefits, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

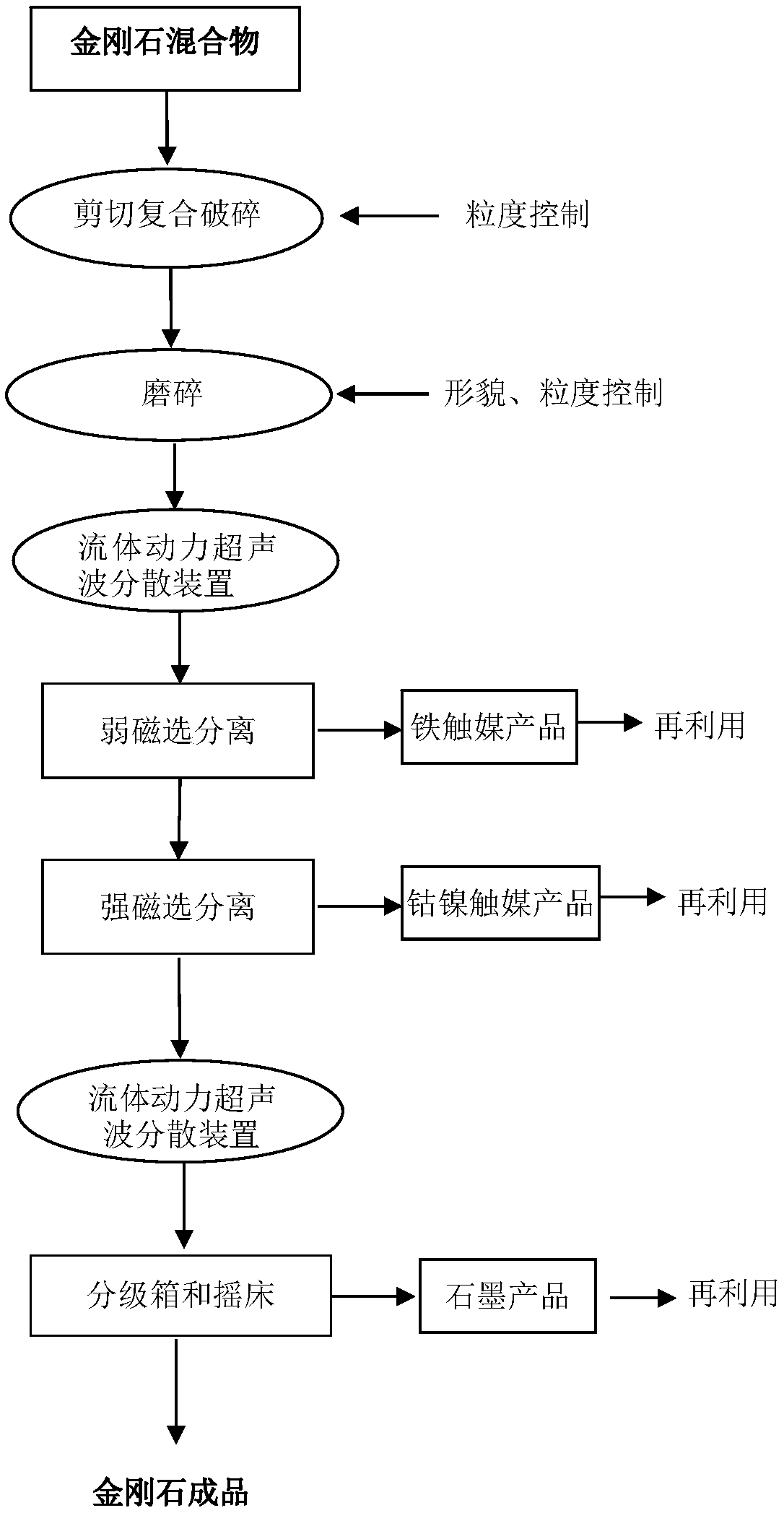

[0062] The invention provides a method for separating diamond mixture, as attached figure 1 shown, including the following steps:

[0063] 1) The mixed material containing iron-cobalt-nickel catalyst, graphite and diamond is sheared and compounded by a squeeze crusher with a shearing function to obtain a material with a particle size of less than 3.0mm; then it is ground by a milling machine, A dissociated and finer-grained ground mixture was obtained with a material content of 70% of particle size -0.074 mm. Among them, the small bat medium, the large wood medium, and the water medium are added to the mill; the ratio of the small bat medium to the large wood medium is 1:2.

[0064] 2) Pass the pulverized mixed material through a hydrodynamic ultrasonic dispersing device for 9 cycles of ultrasonic dispersion treatment to obtain a fully dispersed ultrasonic dispersion mixture.

[0065] 3) The ultrasonic dispersion mixture is first subjected to magnetic separation by a weak ma...

Embodiment 2

[0069] A method for separating a diamond mixture, comprising the steps of:

[0070] 1) The mixed material containing iron-cobalt-nickel catalyst, graphite and diamond is sheared and compounded by a squeeze crusher with a shearing function to obtain a material with a particle size of less than 2.0mm; then it is ground by a milling machine, A dissociated and finer-grained ground mixture was obtained with a material content of -0.074 mm of 80%. Among them, the small bat medium, the large wood medium, and the water medium are added to the mill; the ratio of the small bat medium to the large wood medium is 1:1.

[0071] 2) Pass the pulverized mixed material through a hydrodynamic ultrasonic dispersing device for 11 cycles of ultrasonic dispersion treatment to obtain a fully dispersed ultrasonic dispersion mixture.

[0072] 3) The ultrasonic dispersion mixture is first subjected to magnetic separation by a weak magnetic separator with a magnetic field strength of 120mT to remove th...

Embodiment 3

[0076] A method for separating a diamond mixture, comprising the steps of:

[0077] 1) The mixed material containing iron-cobalt-nickel catalyst, graphite and diamond is sheared and compounded by a squeeze crusher with a shearing function to obtain a material with a particle size of less than 1.5mm; then it is ground by a milling machine, A dissociated and finer-grained ground mixture was obtained with a material content of -0.074 mm of 80%. Among them, the small bat medium, the large wood medium, and the alcohol medium are added to the mill; the ratio of the small bat medium to the large wood medium is 1:2.

[0078] 2) Pass the pulverized mixed material through a hydrodynamic ultrasonic dispersing device for 13 cycles of ultrasonic dispersion treatment to obtain a fully dispersed ultrasonic dispersion mixture.

[0079] 3) The ultrasonic dispersion mixture is first subjected to magnetic separation by a weak magnetic separator with a magnetic field strength of 160mT to remove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com