Contamination-resistant antibacterial cement-based ceramic tile joint mixture preparation method

A caulking agent, cement-based technology, applied in the field of preparation of stain-resistant and antibacterial cement-based tile caulking agent, can solve the problems of human harm, poor stain resistance, accumulation of a lot of dust and dirt, etc. the effect of increasing the diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

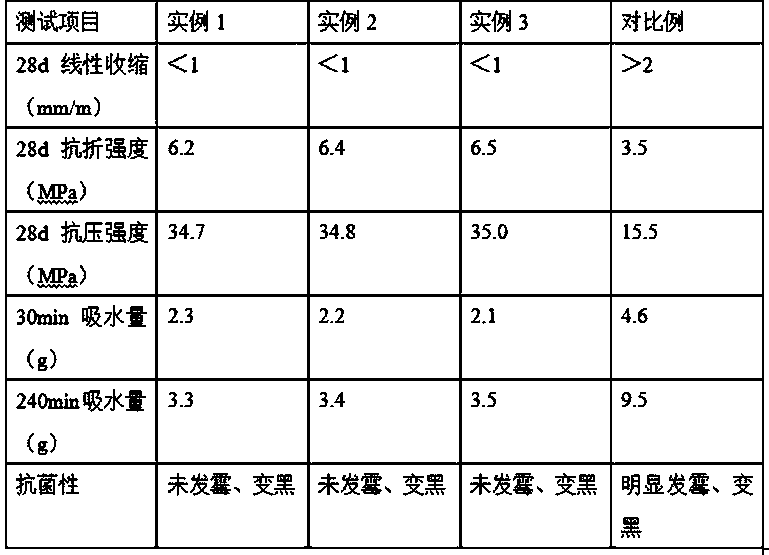

Examples

Embodiment Construction

[0022] Weigh the soybeans and squid and put them into a tissue pulverizer to grind for 20-30 minutes to obtain a mixed pulverized product, put the mixed pulverized product into an iron pot, and then add deionized water 8 to 10 times the weight of the mixed pulverized product into the iron pot, Heat up to 90-100°C, heat-preserve and cook for 1-2 hours to obtain the boiled product; after the above-mentioned boiled product is naturally cooled to room temperature, put it in a glass jar, and place the glass jar open at a temperature of 28-31°C , the relative humidity of the air is 50-60% in the greenhouse where the mold is naturally molded for 5-7 days. After the mold is over, the glass jar is sealed and fermented at a temperature of 35-45°C for 15-20 days. After the fermentation is completed, the fermentation filtrate is obtained by filtration ;Put montmorillonite, attapulgite and gypsum powder into a pulverizer at a mass ratio of 3:2:4 and pulverize for 1 to 2 hours to obtain a mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com