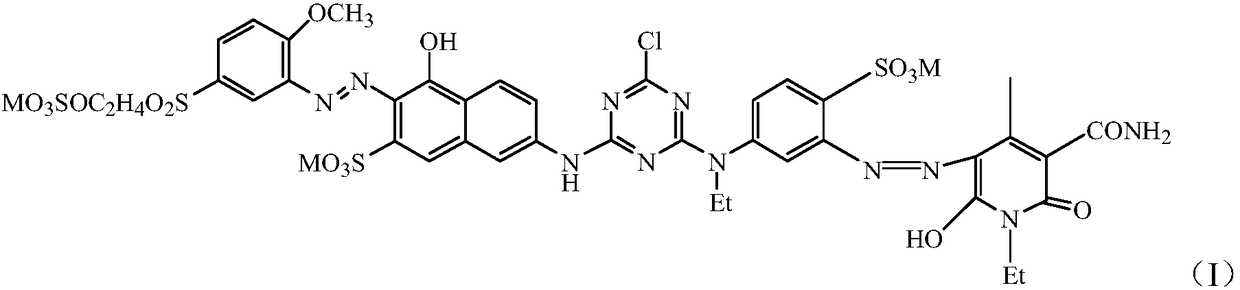

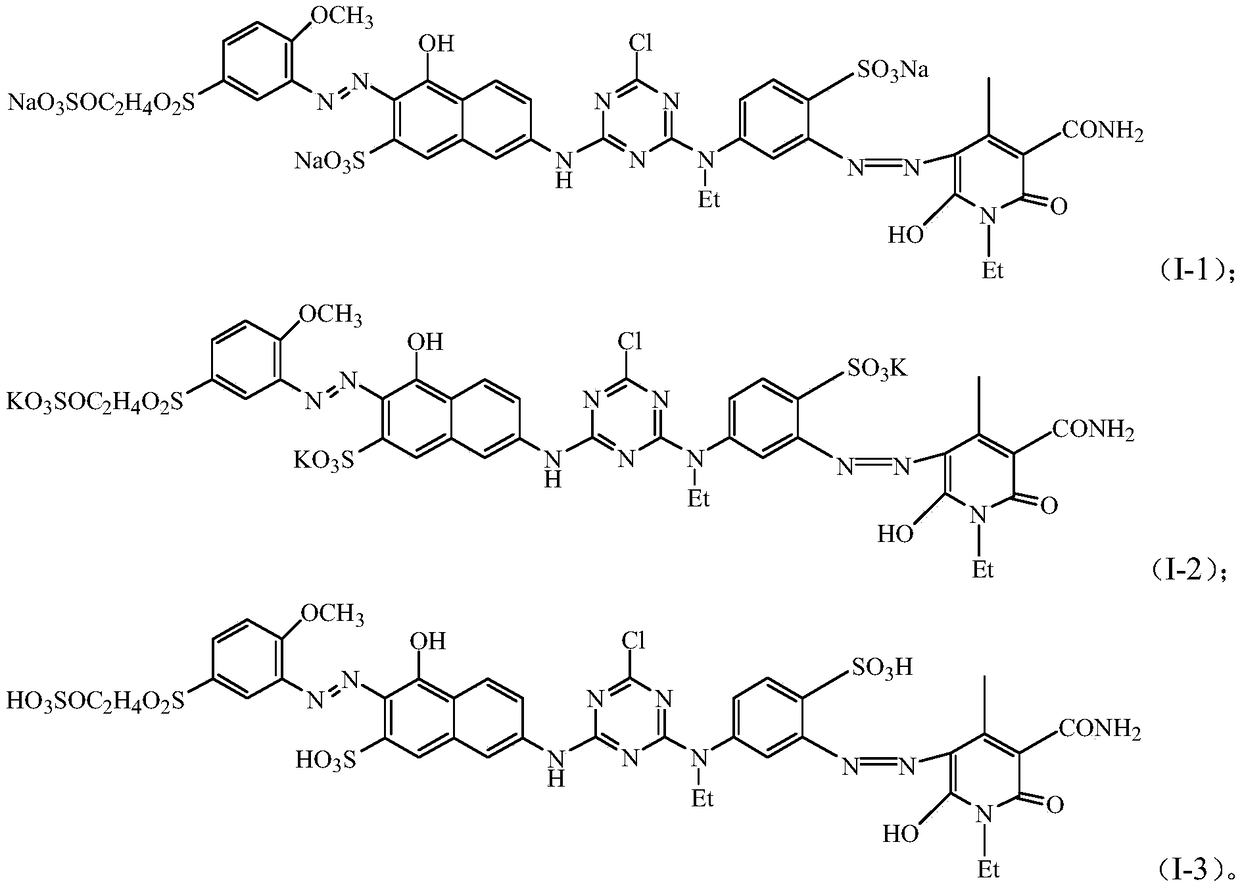

Reactive orange dye as well as preparation method and application thereof

A technology of orange dye and reactive orange, which is applied in the field of textile printing and dyeing, can solve the problems of high salt and high alkali dyeing, limited reactive dyes, low dyeing depth, etc., and achieves the goals of reducing production costs, high product yield, and reducing alkali consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

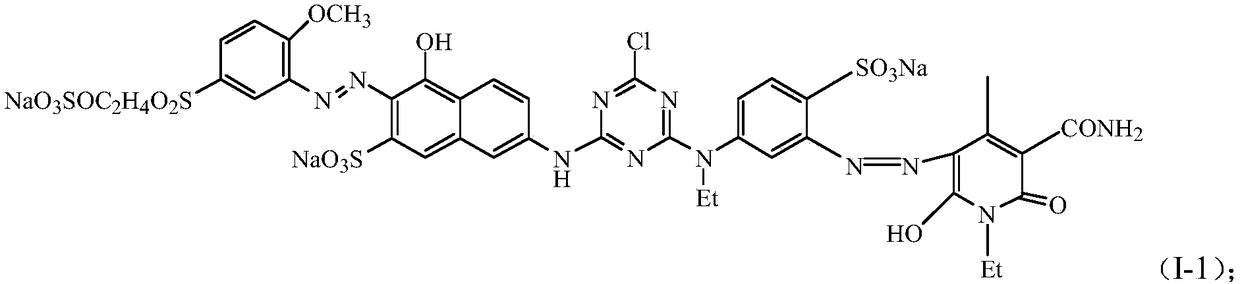

Embodiment 1

[0040] The present embodiment provides a kind of preparation method of active orange dye, it comprises:

[0041] (1) Use at 12±1°C Reacting in an aqueous solution with a pH value of 5.5±0.2 to obtain a first reaction mixed solution;

[0042] (2) Add hydrogen chloride (selection concentration is the hydrochloric acid solution of 33% in the described first reaction mixed solution, and molar ratio is the hydrogen chloride content obtained through calculation, contains hydrogen chloride 54.8g), sodium nitrite 75.9g, at 1 ± 1 Reaction at ℃ to obtain the second reaction mixed solution;

[0043] (3) Add to the second reaction mixture solution Reacting at 6±1°C and at a pH value of 6.5±0.2 to obtain a third reaction mixed solution;

[0044] (4) In the presence of 12g fatty alcohol polyoxyethylene ether, add to the third reaction mixed solution reacting at 40±2°C and at a pH value of 5.5±0.2 to obtain a fourth reaction mixed solution;

[0045] (5) Use at 1±1°C Hydrogen chlori...

Embodiment 2

[0050] The present embodiment provides a kind of preparation method of active orange dye, it comprises:

[0051] (1) Use at 13±1°C Reacting in an aqueous solution with a pH value of 5.6±0.2 to obtain a first reaction mixed solution;

[0052] (2) Add hydrogen chloride (the selected concentration is 33% hydrochloric acid solution, the molar ratio is calculated hydrogen chloride content, containing hydrogen chloride 62g) and sodium nitrite 78g in the first reaction mixed solution, at 1 ± 1 ° C Reaction, obtains the second reaction mixed solution;

[0053] (3) Add to the second reaction mixture solution reacting at 7±1°C and at a pH value of 6.4±0.1 to obtain a third reaction mixed solution;

[0054] (4) In the presence of 16g fatty alcohol polyoxyethylene ether, add to the third reaction mixed solution reacting at 40±2°C and at a pH value of 5.5±0.2 to obtain a fourth reaction mixed solution;

[0055] (5) Use at 1±1°C Hydrogen chloride (selection concentration is the h...

Embodiment 3

[0060] The present embodiment provides a kind of preparation method of active orange dye, it comprises:

[0061] (1) Use at 12±1°C Reacting in an aqueous solution with a pH value of 5.5±0.2 to obtain a first reaction mixed solution;

[0062] (2) Add hydrogen chloride (selection concentration is the hydrochloric acid solution of 33% in the described first reaction mixed solution, and mol ratio is the hydrogen chloride content obtained through calculation, contains hydrogen chloride 55.8g), potassium nitrite 102.1g, in 2 ± 1 Reaction at ℃ to obtain the second reaction mixed solution;

[0063] (3) Add to the second reaction mixture solution reacting at 6±1°C and at a pH value of 6.3±0.2 to obtain a third reaction mixed solution;

[0064] (4) In the presence of 25g fatty alcohol polyoxyethylene ether, add to the third reaction mixed solution reacting at 45±2°C and at a pH value of 5.7±0.2 to obtain a fourth reaction mixed solution;

[0065] (5) Use at 2±1°C Hydrogen chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com