Preparation method for oil slurry scale inhibitor of catalytic cracking apparatus

A catalytic cracking unit and scale inhibitor technology, which is applied in the petroleum industry, hydrocarbon oil treatment, equipment corrosion/scaling inhibition, etc., can solve the problems of no scale inhibition effect, scale inhibitor decomposition, etc., and achieve low production cost and excellent reaction conditions Mild, good anti-scaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

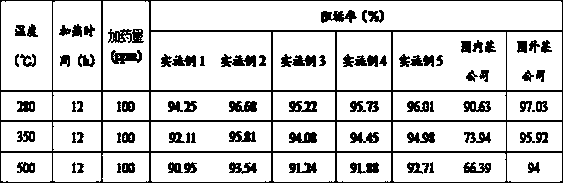

Examples

Embodiment 1

[0022] An oil slurry scale inhibitor used in catalytic cracking units, which contains alcohol ether, polyether, polyester and water.

[0023] The alcohol ether is diethylene glycol butyl ether.

[0024] The polyether is .

[0025] The polyester is polyethylene glycol 400 monooleate.

[0026] The mass ratio of the polyether, alcohol ether, polyester and water is 1:1:1:1.

Embodiment 2

[0028] An oil slurry scale inhibitor used in catalytic cracking units, which contains alcohol ether, polyether, polyester and water.

[0029] The alcohol ether is dipropylene glycol butyl ether.

[0030] The polyether is .

[0031] The polyester is polyethylene glycol 400 dioleate.

[0032] The mass ratio of the polyether, alcohol ether, polyester and water is 1:5:3:4.

Embodiment 3

[0034] An oil slurry scale inhibitor used in catalytic cracking units, which contains alcohol ether, polyether, polyester and water.

[0035] The alcohol ether is ethylene glycol ether.

[0036] The polyether is .

[0037] The polyester is polyethylene glycol 600 monooleate.

[0038] The mass ratio of the polyether, alcohol ether, polyester and water is 1:3:2:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com