Preparation method of gasified water-coal slurry additive

A technology for additive preparation and gasification of coal-water slurry, which is applied in the fields of fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems that the improvement effect of gasification coal-water slurry additives is not obvious and the cost of raw materials is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

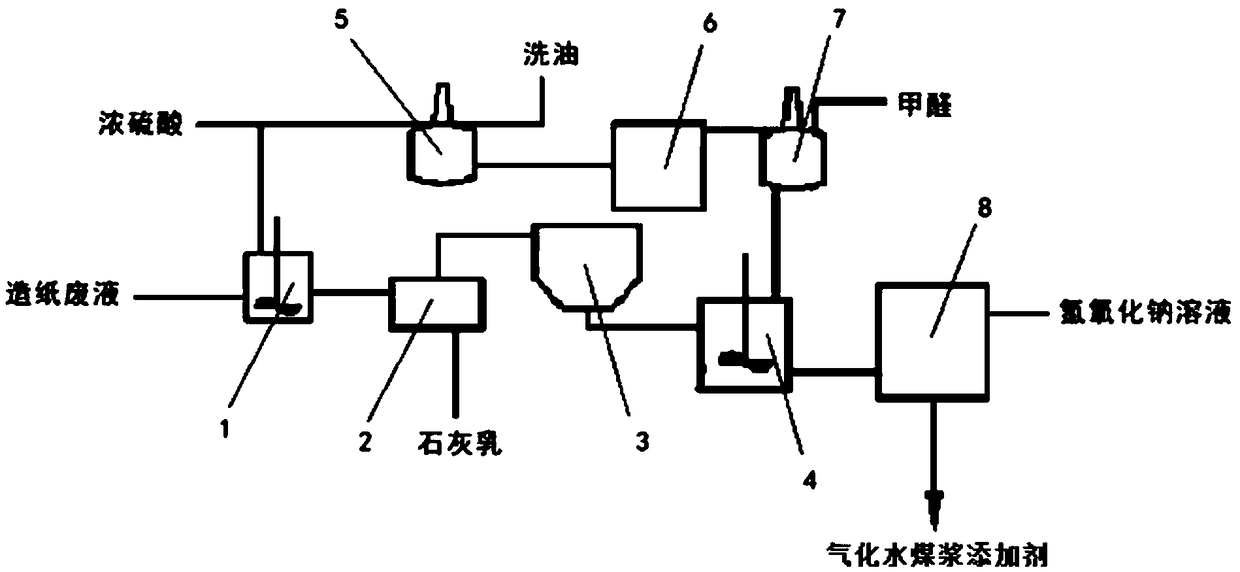

[0032]10t of papermaking waste liquid reacts with 4t of concentrated sulfuric acid with a mass concentration of 90% in the stirring tank 1 for 10h, then reacts with 4t of milk of lime in the settling tank 2 and settles for 20h, the supernatant in the settling tank 2 enters the belt type Filter press, filter at a pressure of 0.1MPa to obtain the filtrate; 3t of washing oil and 1t of concentrated sulfuric acid are reacted in the sulfonation reactor 5 at a reaction temperature of 80°C for 8h, and the obtained reaction liquid and 1t of deionized water enter the hydrolysis Hydrolyze in tank 6 for 20 hours, the obtained hydrolyzate and 2.5t formaldehyde enter the condensation reactor 7, and carry out polycondensation reaction at a reaction temperature of 105°C for 8 hours, and the obtained condensate and the filtrate filtered out by the belt filter press are mixed and stirred Tank 4, the reaction solution obtained by mixing and stirring reaction and 5t of sodium hydroxide solution wi...

Embodiment 2

[0035] 8t of papermaking waste liquid and 3t of concentrated sulfuric acid with a mass concentration of 95% reacted in the stirring tank 1 for 13h, then reacted with 4t of milk of lime in the settling tank 2 and left to settle for 24h, the supernatant in the settling tank 2 entered the belt type Filter press, filter under the pressure of 0.2MPa to obtain the filtrate; 5t of washing oil and 2t of concentrated sulfuric acid are reacted in the sulfonation reactor 5 at a reaction temperature of 80°C for 10h, and the obtained reaction liquid is hydrolyzed with 1t of deionized water Hydrolyze in tank 6 for 24 hours, the obtained hydrolyzate and 3t formaldehyde enter the condensation reactor 7, carry out the polycondensation reaction at a reaction temperature of 105°C for 10 hours, the obtained condensate and the filtrate filtered out by the belt filter press enter the mixing tank 4. The reaction solution obtained by mixing and stirring reaction is neutralized with 6 tons of sodium hy...

Embodiment 3

[0038] 12t of papermaking waste liquid reacted with 4t of concentrated sulfuric acid with a mass concentration of 98% in the stirring tank 1 for 16h, then reacted with 5t of milk of lime in the settling tank 2 and left to settle for 28h, the supernatant in the settling tank 2 entered the belt type Filter press, filter under the pressure of 0.3MPa to obtain the filtrate; 2t of washing oil and 1t of concentrated sulfuric acid are reacted in the sulfonation reactor 5 at a reaction temperature of 80°C for 12h, and then enter the hydrolysis tank 6 with 1t of deionized water Hydrolyze for 28 hours, the obtained hydrolyzate and 2t of formaldehyde enter the condensation reactor 7, carry out the polycondensation reaction at a reaction temperature of 105°C for 12 hours, the obtained condensate and the filtrate filtered out by the belt filter press enter the mixing tank 4, mix The reaction solution obtained by the stirring reaction is neutralized with 4t of sodium hydroxide solution with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com