Anti-wear nanometer copper lubricating oil

A nano-copper and lubricating oil technology, which is applied in the field of lubricating oil, can solve the problems of high surface activity of nano-copper particles, difficulty in maintaining a uniform suspension state, and affecting the anti-wear effect of lubricating oil, so as to improve suspension stability, prevent agglomeration, reduce Effect of Surface Coefficient of Friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

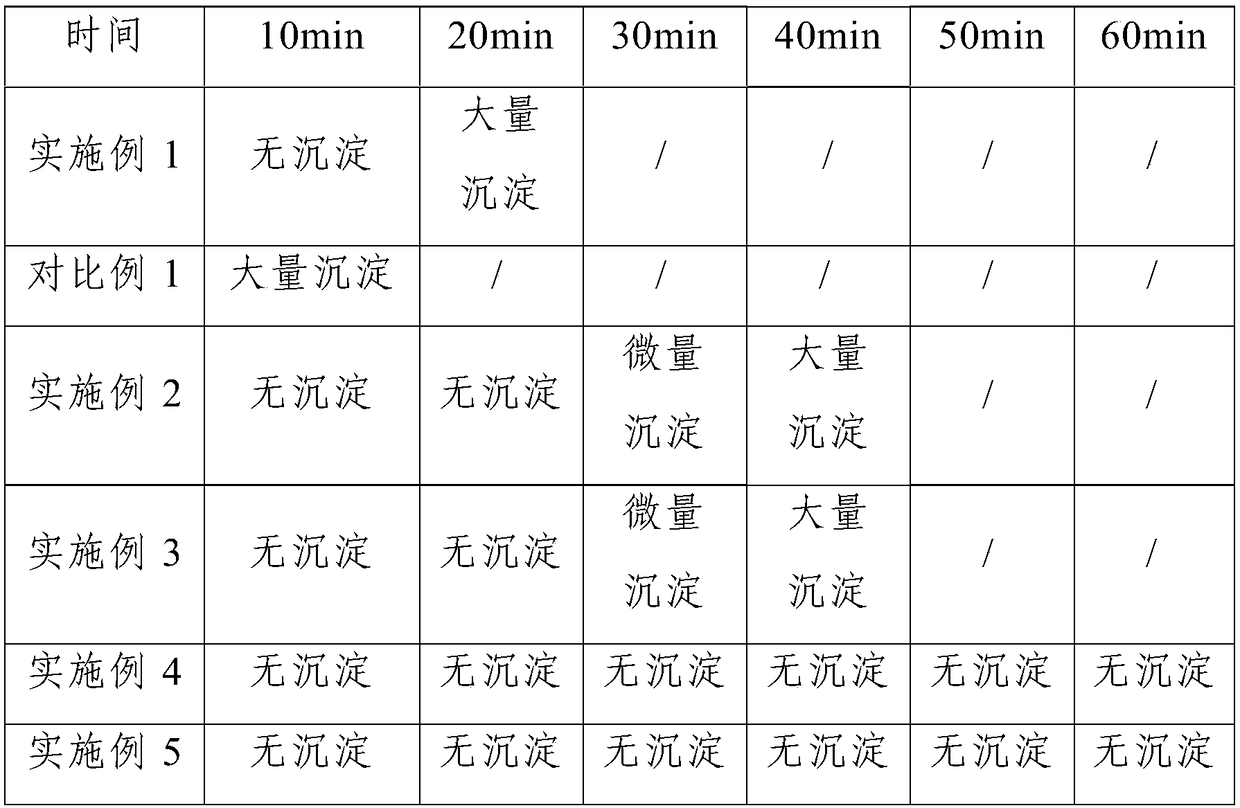

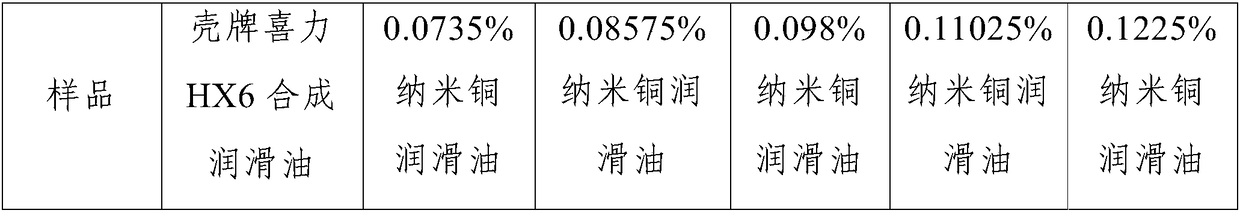

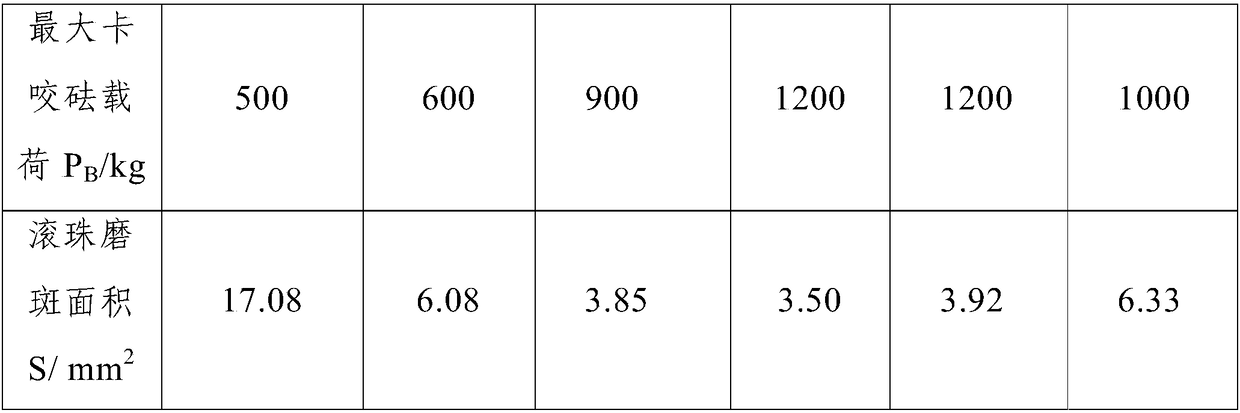

Embodiment 1

[0023] The anti-wear type nano-copper lubricating oil of the present embodiment is prepared by the following method:

[0024] Step 1, 2g polyoxyethylene sorbitan monooleate is added in 100g nano-copper dehydrated alcohol suspension and stirred, obtain mixed solution A; The mass content of nano-copper in the described nano-copper dehydrated alcohol suspension is 25%;

[0025] Step 2. Add 4 g of the mixed solution A obtained in step 1 to 1000 g of Shell Helix HX6 synthetic lubricating oil for ultrasonic dispersion for 30 minutes, then centrifuge at a speed of 200 r / min for 60 minutes, and discard the precipitate to obtain mixed solution B;

[0026] Step 3. The mixed solution B obtained in step 2 is subjected to vacuum distillation at a temperature of 80° C. and a pressure of 0.08 MPa to obtain nano-copper lubricating oil.

Embodiment 2

[0030] The anti-wear type nano-copper lubricating oil of the present embodiment is prepared by the following method:

[0031] Step 1. Add 0.3g polyoxyethylene sorbitan monooleate and 1.7g sorbitan monooleate to 100g nano copper anhydrous ethanol suspension and stir to obtain mixed solution A; the nano copper The mass content of nano copper in the absolute ethanol suspension is 25%;

[0032] Step 2. Add 4 g of the mixed solution A obtained in step 1 to 1000 g of Shell Helix HX6 synthetic lubricating oil for ultrasonic dispersion for 30 minutes, then centrifuge at a speed of 200 r / min for 60 minutes, and discard the precipitate to obtain mixed solution B;

[0033] Step 3. The mixed solution B obtained in step 2 is subjected to vacuum distillation at a temperature of 80° C. and a pressure of 0.08 MPa to obtain nano-copper lubricating oil.

Embodiment 3

[0035] The anti-wear type nano-copper lubricating oil of the present embodiment is prepared by the following method:

[0036] Step 1. Add 0.8g polyoxyethylene sorbitan monooleate and 1.2g sorbitan monooleate to 100g nano copper anhydrous ethanol suspension and stir to obtain mixed solution A; the nano copper The mass content of nano copper in the absolute ethanol suspension is 25%;

[0037] Step 2. Add 4 g of the mixed solution A obtained in step 1 to 1000 g of Shell Helix HX6 synthetic lubricating oil for ultrasonic dispersion for 30 minutes, then centrifuge at a speed of 200 r / min for 60 minutes, and discard the precipitate to obtain mixed solution B;

[0038] Step 3. The mixed solution B obtained in step 2 is subjected to vacuum distillation at a temperature of 80° C. and a pressure of 0.07 MPa to obtain nano-copper lubricating oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com