Copper deposition method for copper-contained cyaniding leaching solution

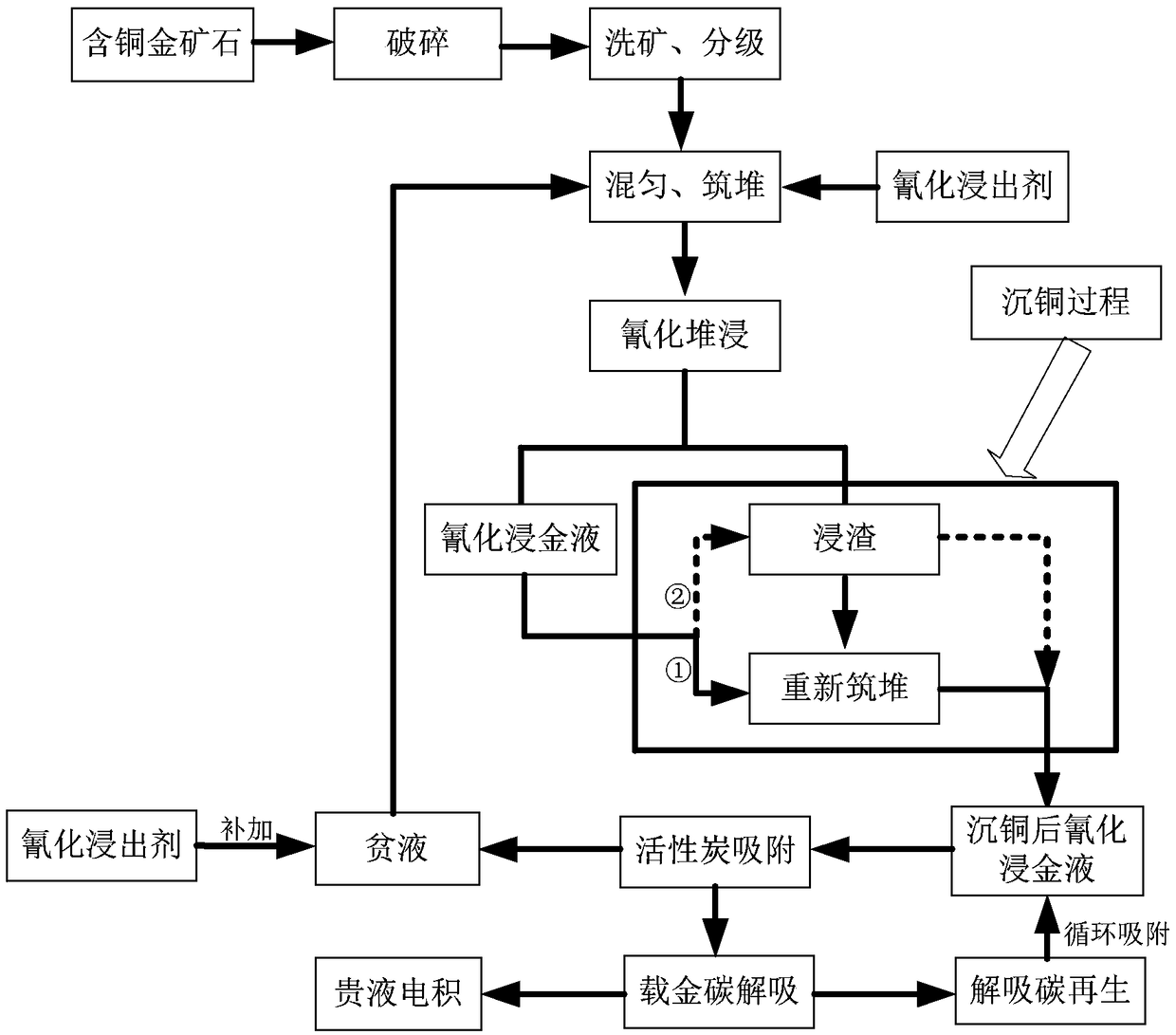

A cyanide leaching and cyanide leaching technology is applied in the field of metallurgy, which can solve the problems of co-adsorption and desorption of gold-loaded carbon, gold and copper, and high copper content in heap leaching solution, and achieves easy operation and control, simple process and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A gold mine contains 0.36g / t of gold and 0.025% of copper (mass percentage, the same below).

[0027] (1) The ore is crushed, the maximum particle size is controlled within 500mm, the ore is washed and piled up, and the alkalinity of the ore pile is adjusted to be 10, and the sodium cyanide solution with a mass concentration of 1 / 10,000 is used at a rate of 12L / (m 2 • Spray the ore heap at a speed of h).

[0028] (2) When the gold ore heap is sprayed and leached to the middle stage, take part of the slag and build a heap with a height of 10 meters.

[0029] (3) the copper-containing cyanidation gold leaching solution obtained in step (1) is mixed with 10L / (m 2 The speed of h) is sprayed into the ore heap of step (2) to deposit copper. Wherein the obtained copper-containing cyanide gold immersion solution in the step (1) has a mass concentration of cyanide radical of 0.008%, a pH value of 9.5, copper-containing 150 mg / L, and gold-containing 0.21 mg / L.

[0030] (4) In ...

Embodiment 2

[0032] A gold mine contains 0.79g / t of gold and 0.083% of copper.

[0033] (1) The ore is crushed, the maximum particle size is controlled within 500mm, the ore is washed and heaped, and the alkalinity of the ore heap is adjusted to be 11, and the concentration is 1 / 10,000 of sodium cyanide solution with 15L / (m 2 • Spray the ore heap at a speed of h).

[0034] (2) When the gold ore heap is sprayed and leached to the middle stage, take part of the slag and build a heap with a height of 20 meters.

[0035] (3) the copper-containing cyanidation gold leaching solution obtained in step (1) is mixed with 13L / (m 2 The speed of h) is sprayed into the ore heap of step (2) to deposit copper. Wherein step (1) the cyanide mass concentration of the obtained copper-containing cyanidation gold immersion solution is 0.009%, pH value 9.0, containing copper 178mg / L, containing gold 0.28mg / L.

[0036] (4) In the cyanidation gold leaching solution after copper precipitation in the mine heap, t...

Embodiment 3

[0039] A gold mine contains 0.33g / t gold and 0.027% copper.

[0040] (1) The ore is crushed, the maximum particle size is controlled within 500mm, the ore is washed and piled up, and the alkalinity of the ore pile is adjusted to be 10, and the sodium cyanide solution with a mass concentration of 1 / 10,000 is used at a rate of 10L / (m 2 • Spray the ore heap at a speed of h).

[0041] (2) When the gold ore heap is sprayed and leached to the middle stage, take part of the slag and build a heap with a height of 15 meters.

[0042] (3) the copper-containing cyanidation gold leaching solution obtained in step (1) is mixed with 15L / (m 2 The speed of h) is sprayed into the ore heap of step (2) to deposit copper. Wherein step (1) the cyanide mass concentration of the obtained copper-containing cyanidation gold immersion solution is 0.008%, pH value 9.0, containing copper 159mg / L, containing gold 0.23mg / L.

[0043] (4) In the cyanidation gold leaching solution after copper precipitatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com