Preparation method of SERS (Surface-Enhanced Raman Scattering) chip

A chip and pit technology, applied in the field of SERS chip preparation, can solve the problems of difficulty in meeting detection requirements, limited output and high production cost, and achieve the effects of good SERS activity, low cost and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

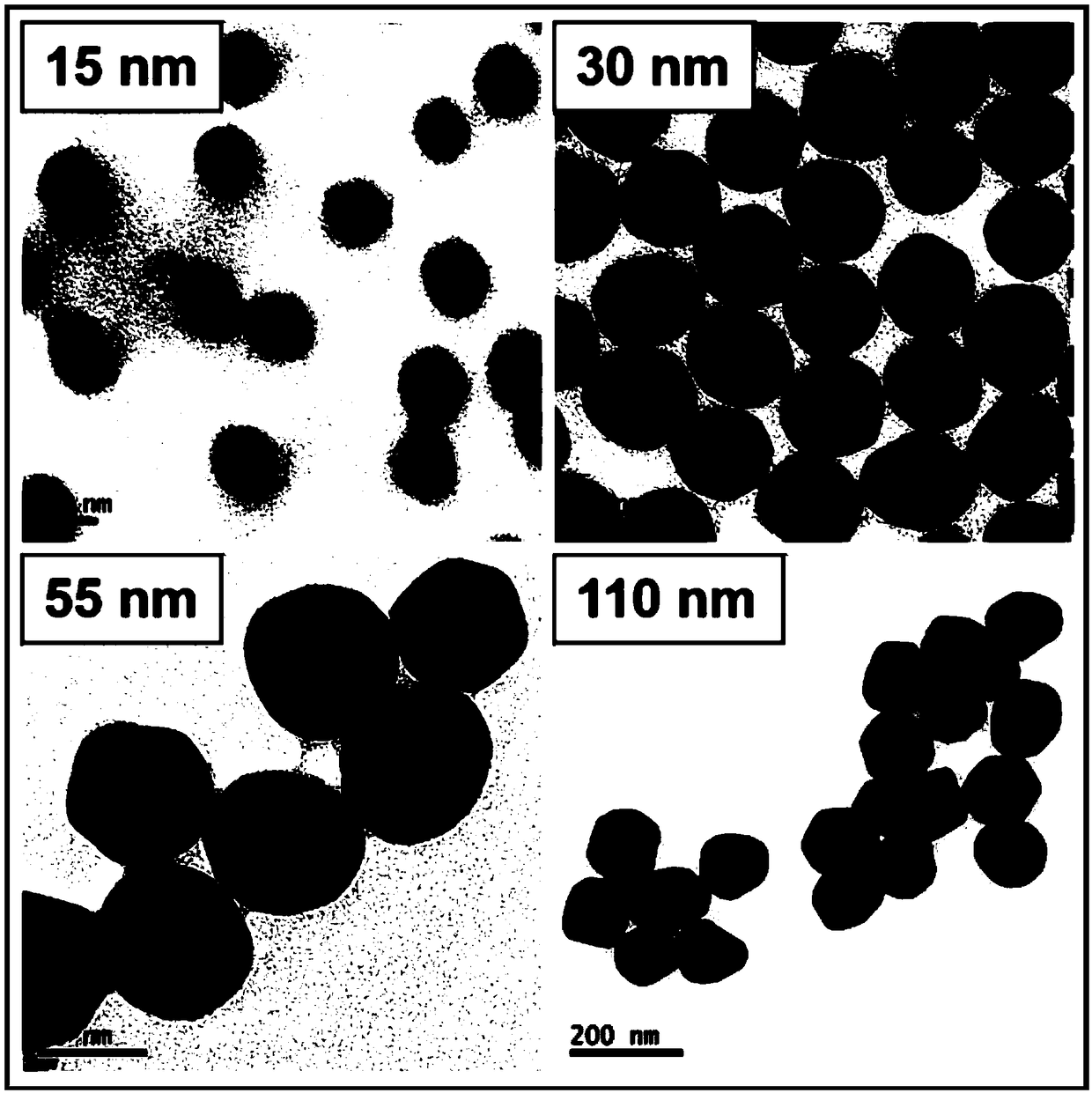

[0071] 1mL HAuCl 4 (25mM) was diluted to 100mL, heated to boiling, and 750uL of sodium citrate aqueous solution (1.14g diluted to 100mL) was added under vigorous stirring. Continue heating for 15 minutes to obtain Au sol with a particle size of 50 nm and a concentration of about 7.5×10 9 individual / mL. The size of the obtained Au nanoparticles can be adjusted by changing the amount of sodium citrate added. figure 1 The TEM images of several Au nanoparticles with different sizes are shown, among which, the upper left image is the TEM image of Au nanoparticles with a particle size of 15nm prepared by adding 2000uL sodium citrate, and the upper right image is the particle obtained by adding 1000uL sodium citrate. The TEM image of Au nanoparticles with a diameter of 30nm, the lower left image is the TEM image of Au nanoparticles with a particle size of 55nm prepared by adding 700uL sodium citrate, and the lower right image is the particle size of 110nm prepared with 300uL sodium...

Embodiment 2

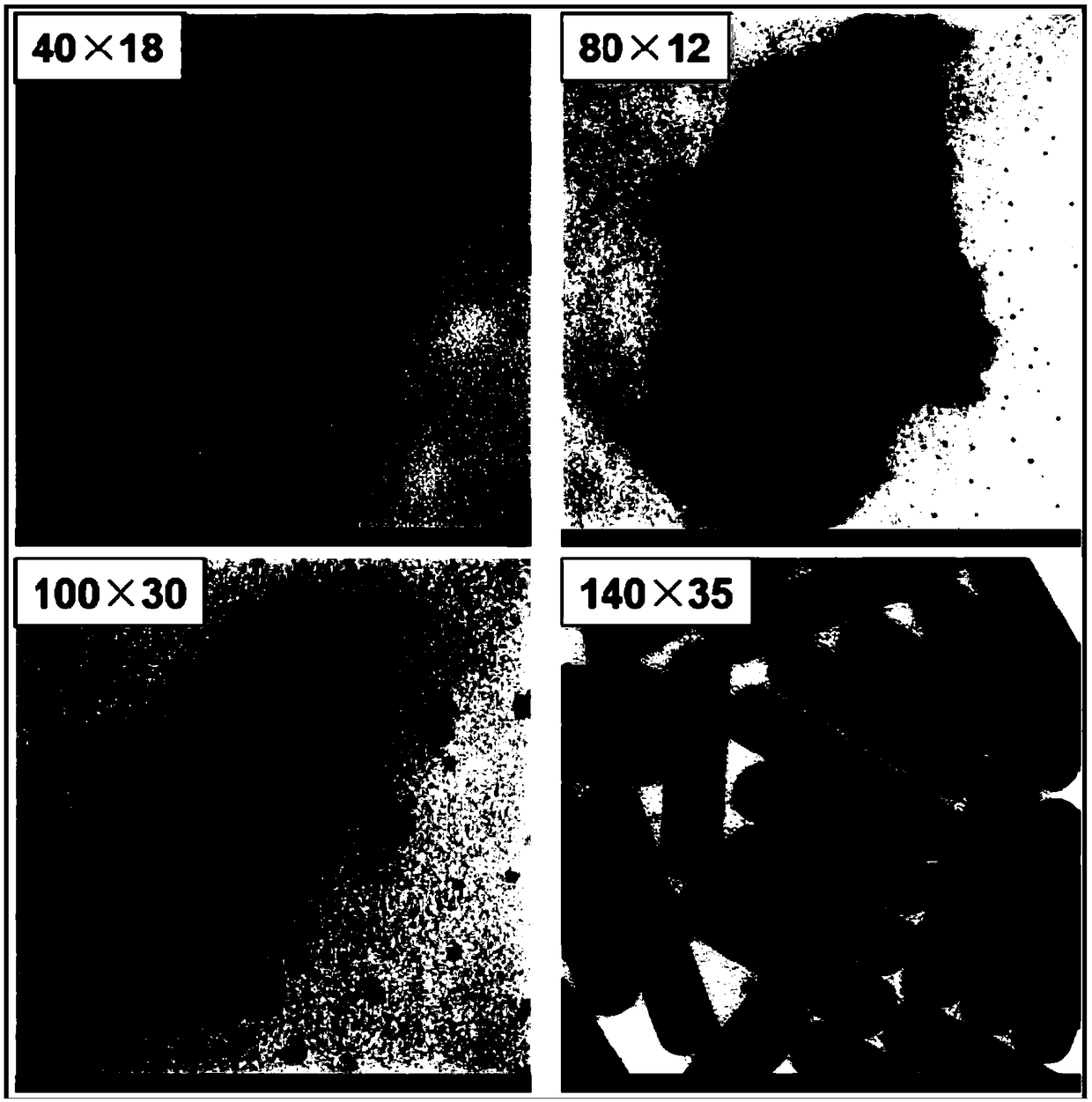

[0073] Seed preparation: Dissolve 0.3645g CTAB (cetyltrimethylammonium bromide) in 9.9mL water, dissolve in water bath at 60°C, add 100uL 1% (w / v%) HAuCl after cooling to 30°C 4 aqueous solution; add 1 mL of 6 mM NaBH with vigorous stirring 4 Aqueous solution, after stirring vigorously for 2 minutes, let stand for 30 minutes before use. Seed growth: 0.9g CTAB and 0.1400g sodium oleate were dissolved in 25mL water, dissolved in a water bath at 60°C, and cooled to 30°C. Add 1.8mL 4mM AgNO 3 Aqueous solution, let stand for 15min, add 25mL 1mM HAuCl at 700rpm 4 Aqueous solution, stir for 90min; add 150uL concentrated hydrochloric acid, and continue stirring at 400rmp for 15min. Finally, 125uL of 0.064MAA (ascorbic acid) aqueous solution was added, vigorously stirred for 30s, 40uL of seeds were added, vigorously stirred for 30s and then left to stand for 12h, finally rod-shaped Au nanoparticles were obtained. The size of the final nanorods can be controlled by adjusting the amo...

Embodiment 3

[0077] Step (1), providing a solid phase template with pits formed on the surface;

[0078] Step (2), the nanoparticle concentration that embodiment 1 makes is about 7.5 * 10 9 A / mL dilute solution was concentrated to obtain a nanoparticle concentration of about 1×10 11 A / mL ink;

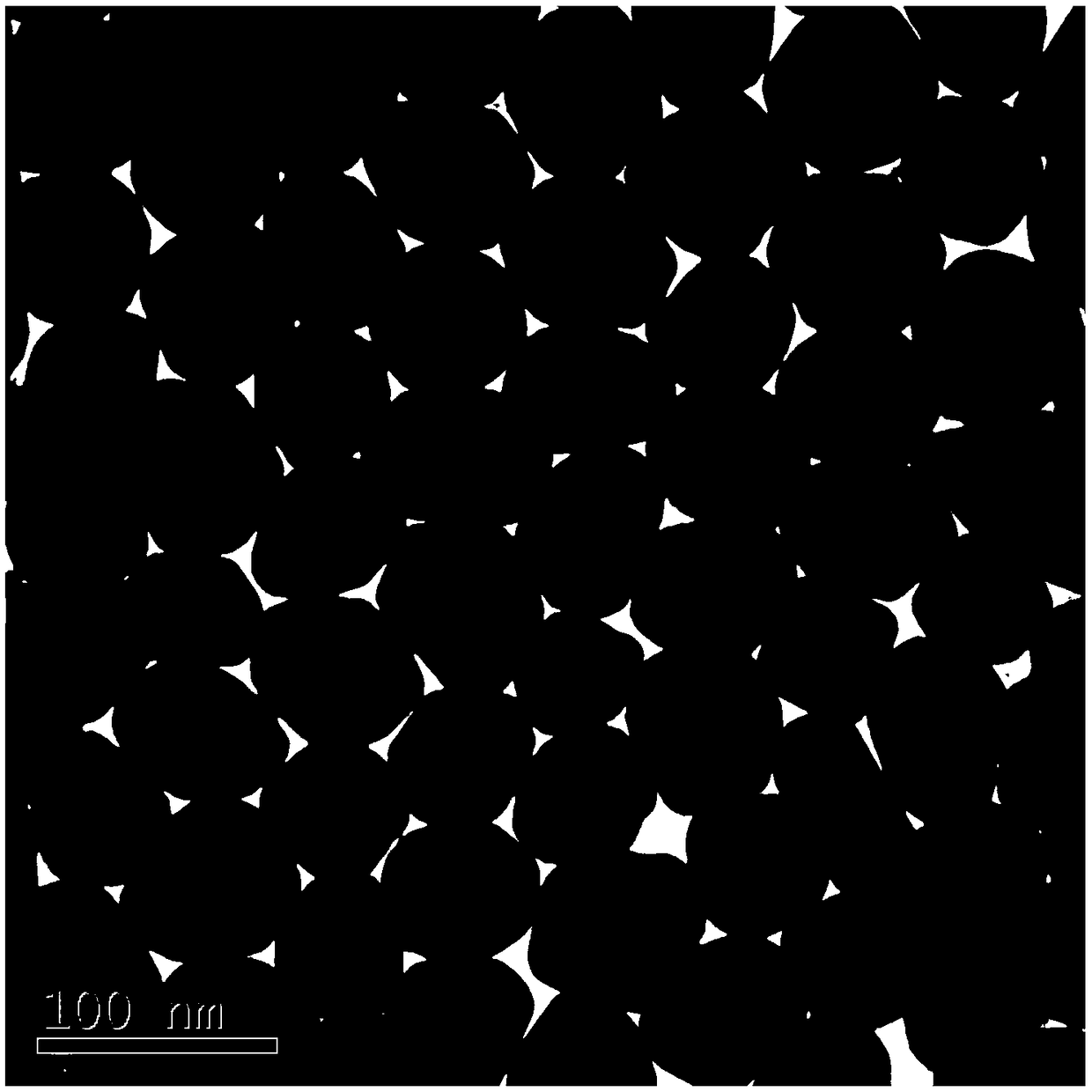

[0079] Step (3), spray the ink obtained in step (2) onto the solid-phase stencil of step (1) with ultrasonic spraying equipment, the number of sprays is 2 times, the ambient temperature during spraying is 25 ° C, and dry to obtain the SERS chip, For a TEM image of the chip see Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com