Y-doped pseudo-ternary semi-conductive cooling material and preparation method therefor

A semiconductor and refrigeration technology, applied in the field of semiconductor refrigeration materials and their preparation, can solve problems such as splitting, and achieve the effects of easy hot pressing, improved mechanical properties, and increased size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

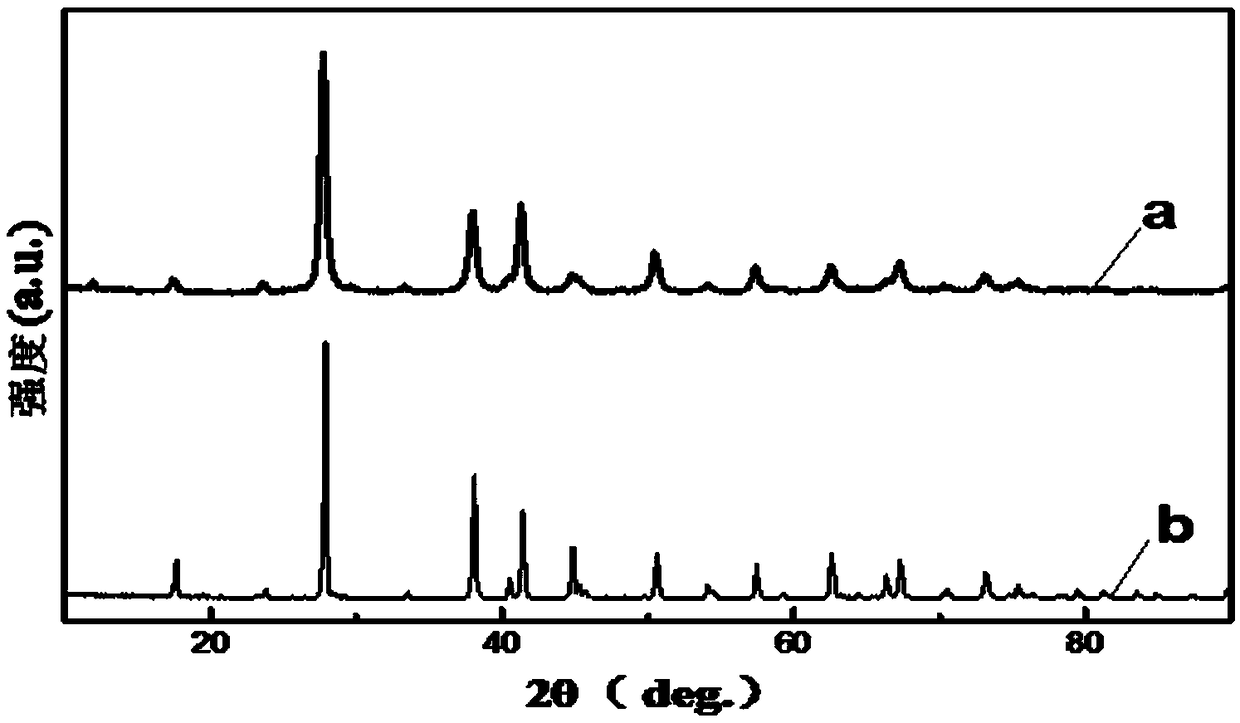

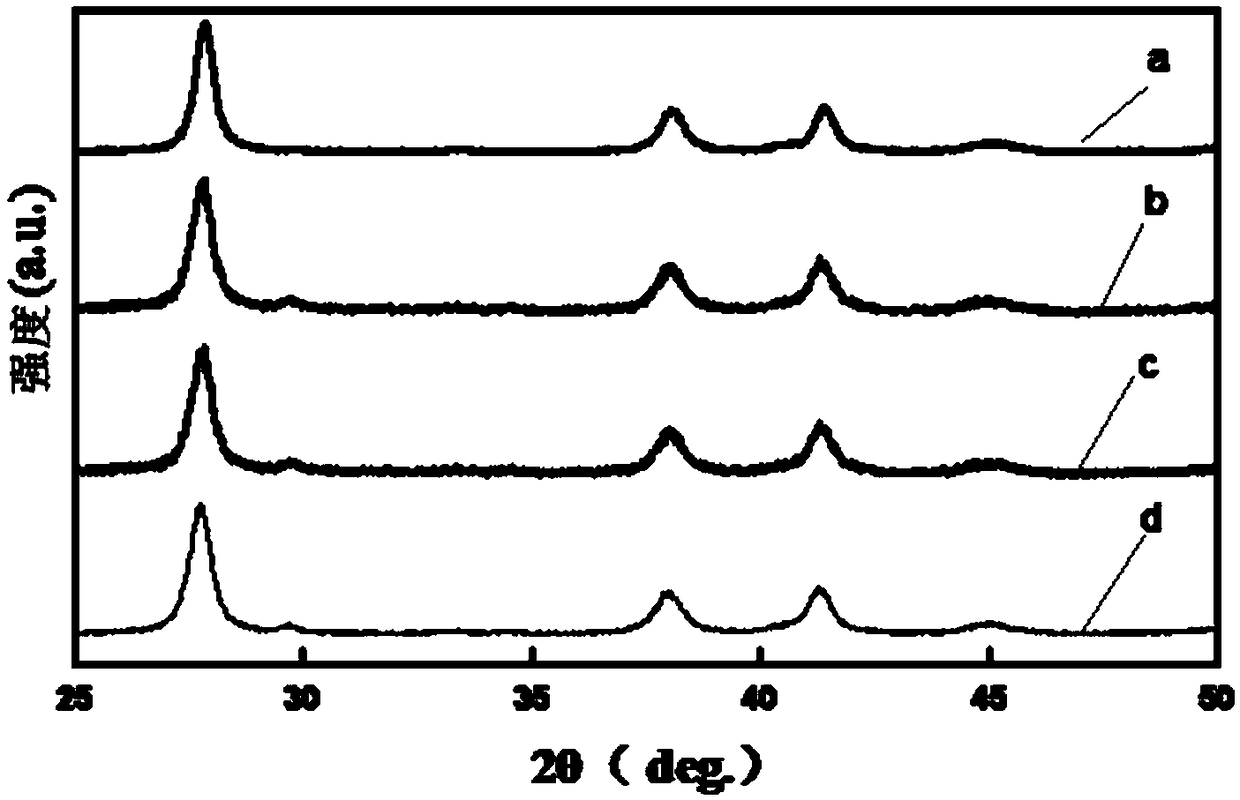

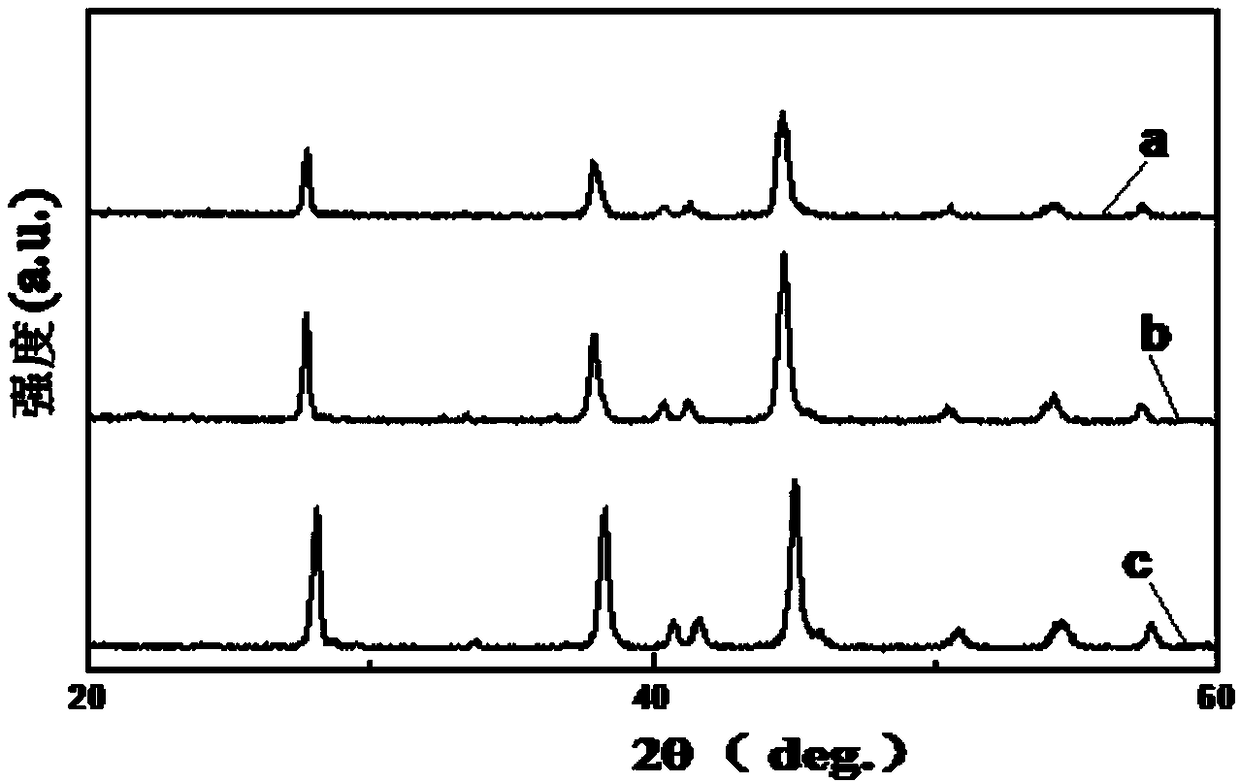

[0045] Specific implementation mode one: the molecular formula of the Y-doped pseudo-ternary semiconductor refrigeration material in this implementation mode is: (Bi 2 Te 3 ) (1-2x) (Sb 2 Te 3 ) x (Bi 2 Se 3 ) x -Y, x in the molecular formula is 0.04-0.06; the mass fraction of Y in the Y-doped pseudo-ternary semiconductor refrigeration material is 1-6%.

[0046] Principle and beneficial effect of this embodiment:

[0047] 1. In this embodiment, Y doping is used to improve the carrier transport mechanism in the material. In this embodiment, the conductivity and thermal conductivity of the Y-doped pseudo-ternary semiconductor refrigeration material vary with the doping concentration when the doping concentration is less than 4%. The increase of impurity concentration first increases and then decreases; the Y doping concentration is 1%, and the thermoelectric figure of merit is 0.73 when hot-pressed at 200°C; the maximum Seebeck coefficient of the Y-doped pseudo-ternary s...

specific Embodiment approach 2

[0049] Specific embodiment two: the preparation method of present embodiment Y-doped pseudo-ternary semiconductor refrigeration material is carried out according to the following steps:

[0050] 1. Raw material weighing

[0051] According to the molecular formula: (Bi 2 Te 3 ) (1-2x) (Sb 2 Te 3 ) x (Bi 2 Se 3 ) x The stoichiometric ratio of tellurium powder, bismuth powder, antimony powder and selenium powder is weighed, and x is 0.04~0.06 in the molecular formula; Yttrium powder is weighed simultaneously, and mixed with tellurium powder, bismuth powder, antimony powder and selenium powder as raw material;

[0052] The mass fraction of yttrium powder in the raw material is 1% to 6%;

[0053] 2. Mechanical alloying

[0054] The raw materials are placed in a ball mill for mechanical alloying to obtain Y-doped pseudo-ternary mechanical alloyed powder materials;

[0055] 3. Vacuum high temperature sintering of samples

[0056] Dry the Y-doped pseudo-ternary mechanical ...

specific Embodiment approach 3

[0065] Embodiment 3: This embodiment is different from Embodiment 2 in that: the purity of the yttrium powder, tellurium powder, bismuth powder, antimony powder and selenium powder in step 1 is 99.99%. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com