A kind of carbon fiber material with deposited sulfur element and its preparation method and application

A carbon fiber material and carbon fiber technology, applied in the field of battery materials, can solve the problems of inability to meet the application requirements of lithium-sulfur batteries, high cost, cumbersome steps, etc., and achieve the effects of improving charge-discharge cycle performance, improving cycle life, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Cobalt oxide modified cotton-based carbon fiber preparation:

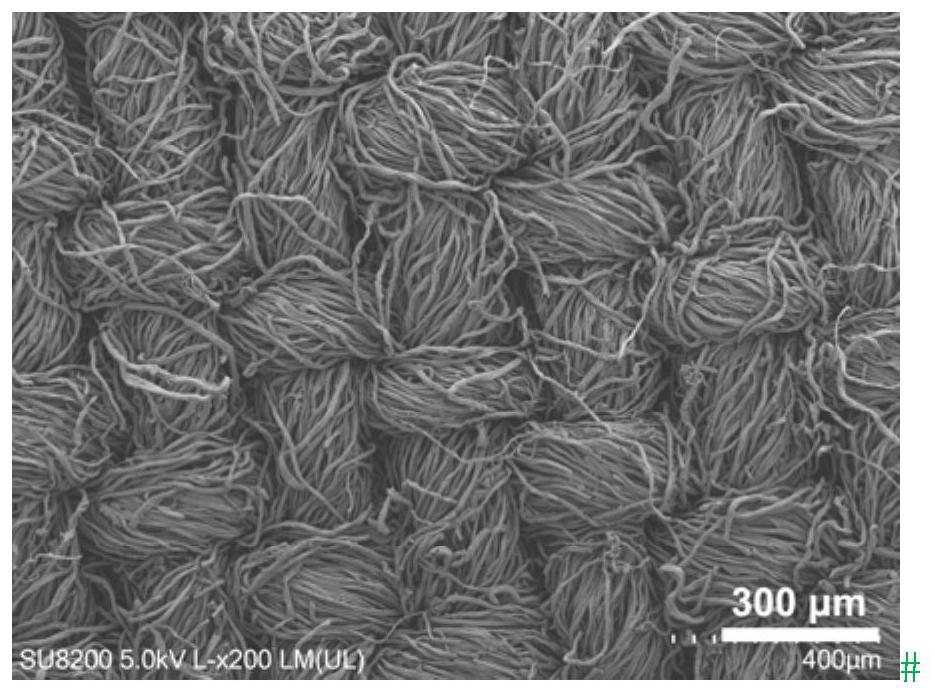

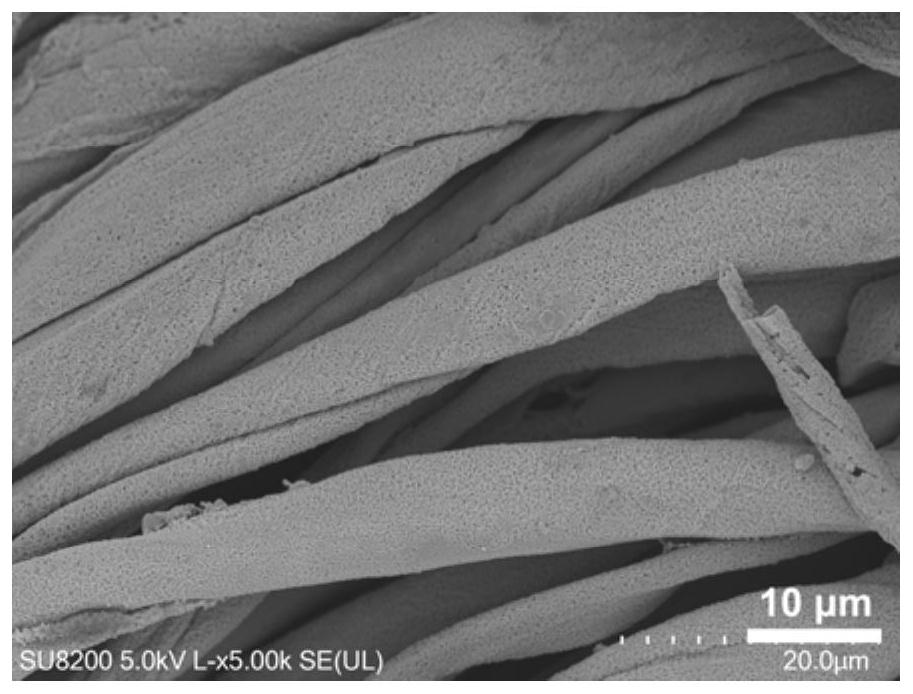

[0034] Weigh 5.0g of cotton fiber cloth, soak it in the cobalt chloride solution with a concentration of 1M for 10min, take it out and rinse it with deionized water. The cotton fiber cloth adsorbed with cobalt chloride was immersed in the sodium sulfide solution with a concentration of 1M for 10 minutes, then taken out and rinsed with deionized water. Repeat this process 5 times to obtain cobalt sulfide-modified cotton fiber cloth. Cobalt sulfide-modified cotton fiber cloth was dried in an oven at 80 °C for 10 h, and then placed in a tube furnace for carbonization treatment. The carbonization treatment temperature was 900 °C, the heating rate was 5 °C / min, and the atmosphere was argon. After the carbonization is completed, the cobalt oxide-modified cotton-based carbon fiber is obtained after naturally cooling to room temperature. figure 1 It can be seen that the prepared cobalt oxide-modified cotton-based ...

Embodiment 2

[0039] Weighed 0.4 g of the prepared cobalt oxide-modified cotton-based carbon fiber and placed it in a closed quartz tube, added 0.6 g of sulfur powder, and treated it at 155° C. for 5 hours to obtain the positive electrode material. Other conditions were the same as in Example 1.

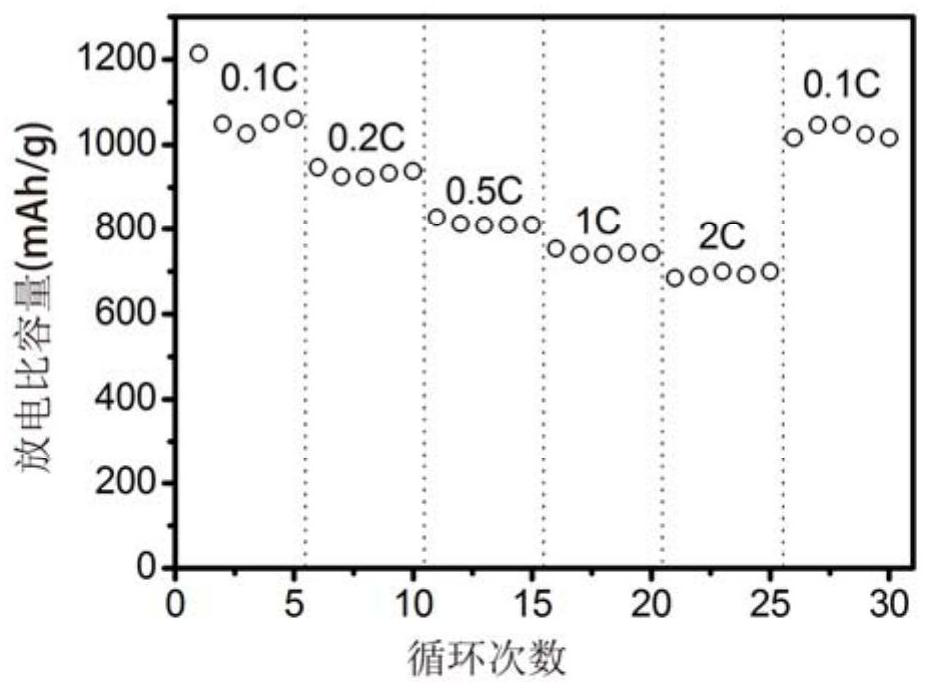

[0040] The positive electrode material prepared above, separator and lithium sheet were assembled into a lithium-sulfur button battery, and the charge-discharge cycle performance test was carried out. When charging and discharging at a constant current of 0.2C (335.0mA / g), the specific capacity of the first discharge of the positive electrode reached 1100mAh / g , the capacity remained at 805mAh / g after 100 cycles.

Embodiment 3

[0042] Weighed 0.2 g of the prepared cobalt oxide-modified cotton-based carbon fiber and placed it in a closed quartz tube, added 0.8 g of sulfur powder, and treated it at 155° C. for 5 hours to obtain the positive electrode material. Other conditions were the same as in Example 1.

[0043] The positive electrode material prepared above, separator and lithium sheet were assembled into a lithium-sulfur button battery, and the charge-discharge cycle performance test was carried out. When charging and discharging at a constant current of 0.2C (335.0mA / g), the specific capacity of the first discharge of the positive electrode reached 790mAh / g , the capacity remained at 621mAh / g after 100 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com