Radiation sensitive resin composition and electronic component

A resin composition and sensitive technology, applied in the direction of photosensitive materials, instruments, and opto-mechanical equipment used in opto-mechanical equipment, can solve the problems of high elastic modulus and warpage of resin films, and achieve excellent thermal shock resistance. , the effect of excellent developability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0109] The preparation method of the radiation-sensitive resin composition of the present invention is not particularly limited, as long as each component constituting the radiation-sensitive resin composition is mixed by a known method.

[0110] The mixing method is not particularly limited, but it is preferable to mix a solution or a dispersion obtained by dissolving or dispersing each component constituting the radiation-sensitive resin composition in a solvent. Accordingly, the radiation-sensitive resin composition can be obtained in the form of a solution or a dispersion.

[0111] The method of dissolving or dispersing each component which comprises a radiation-sensitive resin composition in a solvent should just follow a conventional method. Specifically, it can be performed using a stirring bar and a magnetic stirrer, a high-speed homogenizer, a disperser, a planetary mixer, a twin-shaft mixer, a ball mill, a three-roll machine, or the like. In addition, after dissolvi...

Embodiment 1

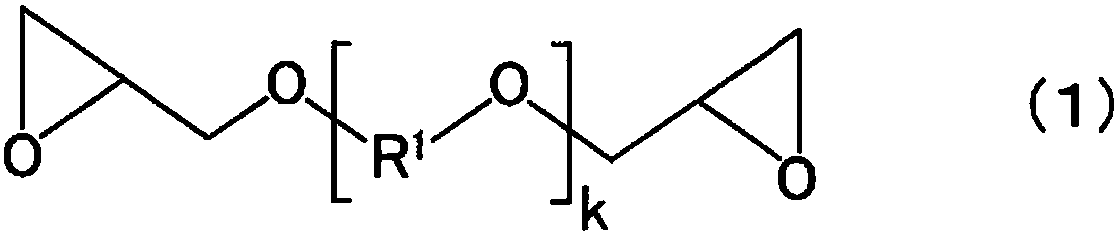

[0159] 291 parts (100 parts based on the cyclic olefin polymer (A-1)) of the cyclic olefin polymer obtained in Synthesis Example 1 as the cyclic olefin polymer (A) having a protic polar group were mixed (A-1) polymer solution, 10 parts of a bifunctional linear epoxy compound (trade name "jER YX7400", manufactured by Mitsubishi Chemical Corporation, epoxy equivalent: 440) as a bifunctional linear epoxy compound (B) , the softening point is below 25°C (liquid at normal temperature), in the above general formula (1), R 1 =-C 4 h 8-, k = about 10 compounds), 30 parts of 4,4'-[1-[4-[1-[4-hydroxyphenyl]-1-methylethyl) as the radiation-sensitive compound (C) ]phenyl]ethylene]biphenyl (1 mole) and 1,2-naphthoquinonediazide-5-sulfonyl chloride (2.0 moles) condensation product (trade name "TS200", manufactured by Toyosei Co., Ltd.), 10 Parts of N,N,N',N',N",N"-hexamethoxymethylmelamine (trade name "NIKALAC MW-100LM ", manufactured by Sanwa Chemical Co., Ltd.), 2 parts of γ-glycidoxy...

Embodiment 2

[0162] In Example 1, the compounding amount of the bifunctional linear epoxy compound (trade name "jER YX7400", manufactured by Mitsubishi Chemical Corporation) was changed from 10 parts to 30 parts, except that it was carried out in the same manner as in Example 1, A radiation-sensitive resin composition was prepared, and measured and evaluated in the same manner. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com