Zero emission circulating system for sealing treatment of regenerated lead smelting tail gas

A secondary lead smelting and sealing treatment technology, which is applied in the direction of gas treatment, combined equipment, and alkali metal sulfite preparation, can solve the problems that affect the economic benefits of enterprises, lead dust is easy to exceed the standard, and caustic soda consumption increases. It is conducive to harmless treatment, reduces the difficulty of flue gas treatment, and reduces the effect of tail gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

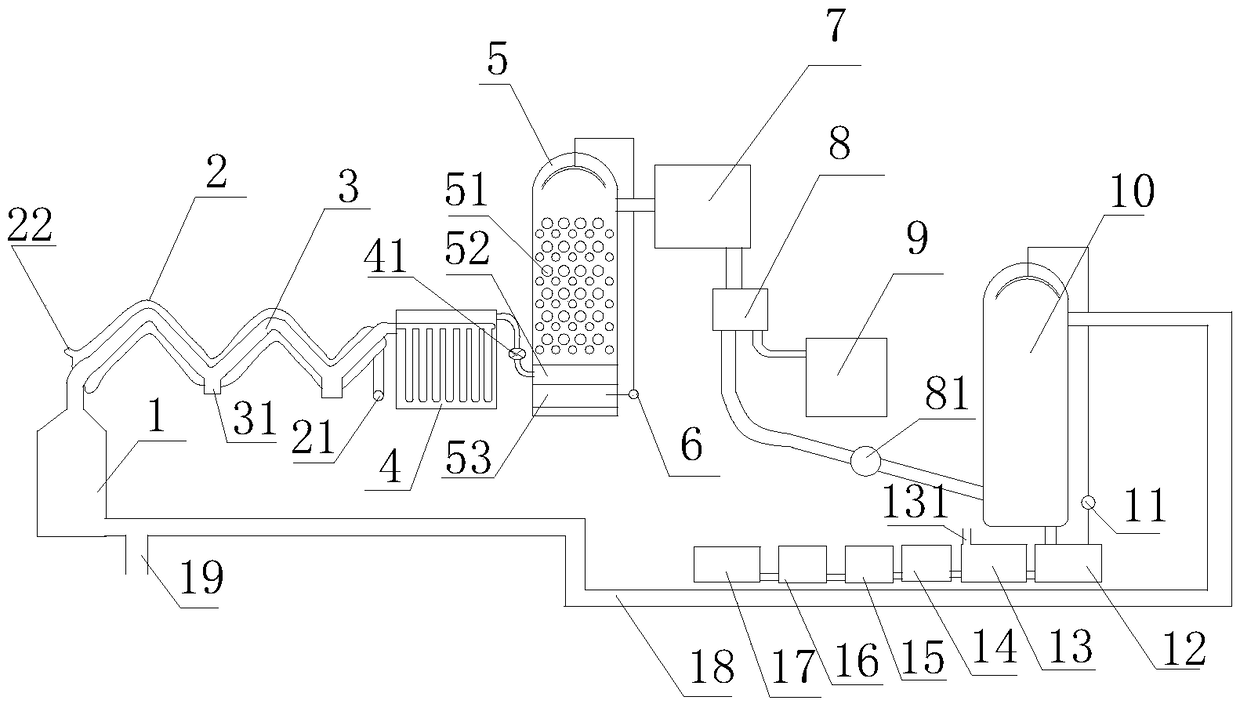

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0022]A zero-emission circulation system for the closed treatment of recycled lead smelting tail gas according to the present invention is provided with a smelting furnace 1, a gravity dust collector 3, a bag filter 4, a water washing dust removal tower 5, an air compressor 7, Gas-liquid separator 8, alkali washing desulfurization tower 10, circulation pipe 18, said gravity deduster 3 is covered with waste heat exchanger 2, and the liquid separated by said gas-liquid separator 7 is passed into drying tank 9, so The pipeline between the bag filter 4 and the water washing dedusting tower 5 is provided with an induced draft fan 41, and the pipeline between the gas-liquid separator 8 and the alkali washing desulfurization tower 10 is provided with an exhaust fan 81, and the circulation One end of the pipe 18 is connected to the exhaust port of the alkali washing desulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com