A kind of modified ABS foam material and preparation method thereof

A foaming material and modification technology, applied in the field of foaming materials, can solve problems such as the difficulty of preparing ABS foam, achieve the effects of increasing the compatibility of various substances, good foaming performance, and improving the degree of uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

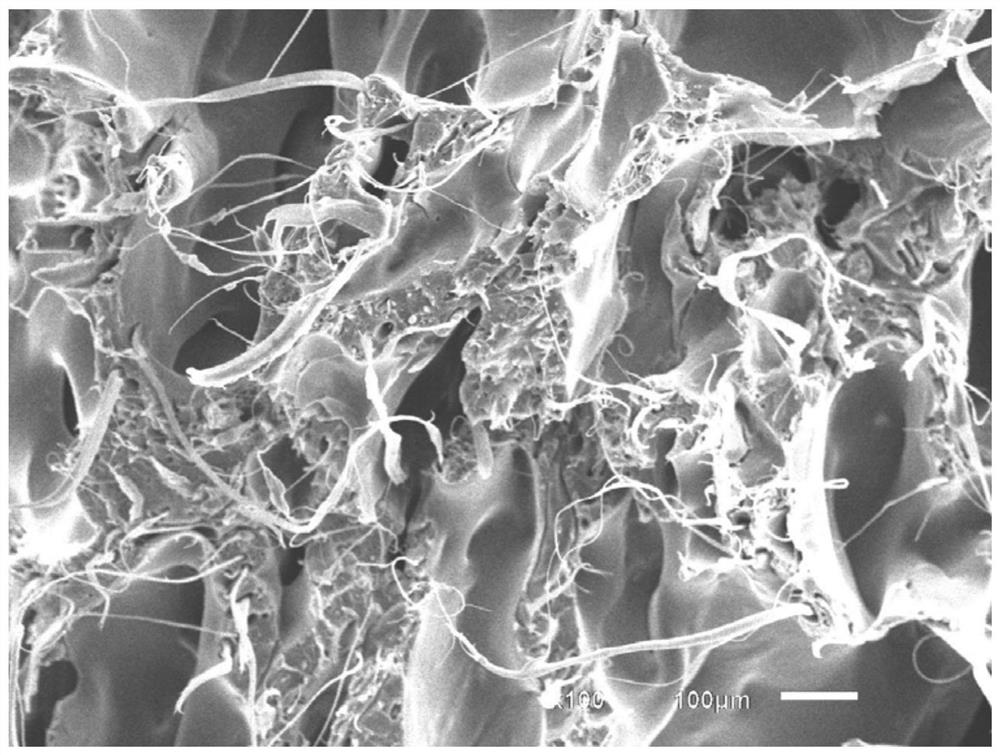

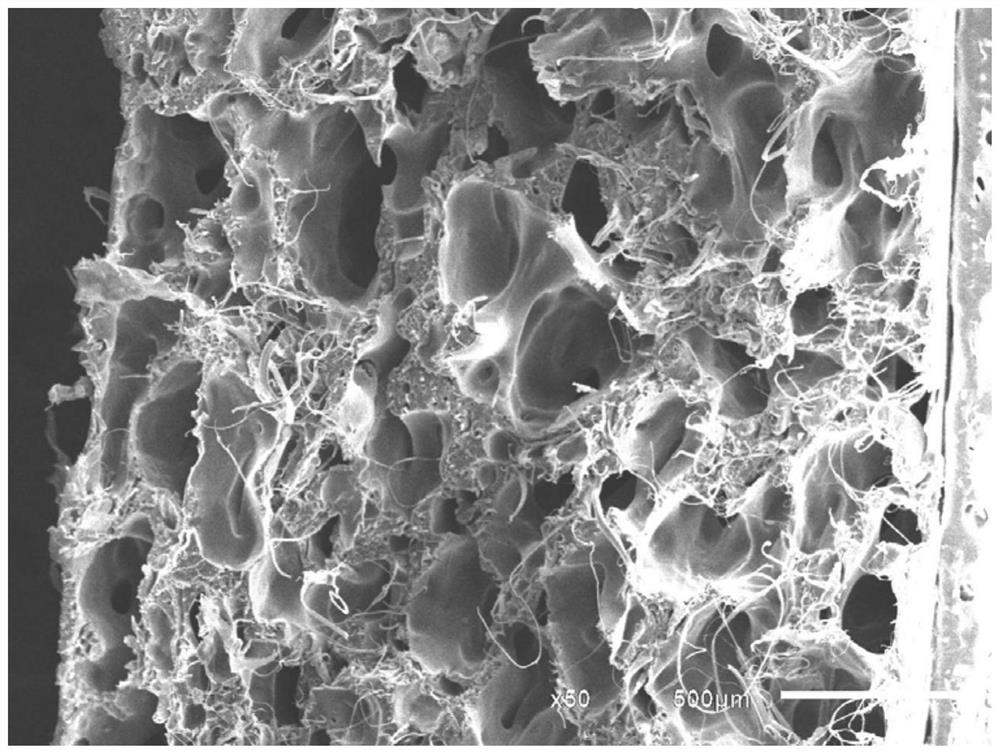

Image

Examples

Embodiment 1

[0021] The modified ABS foaming material is made of ABS resin particles comprising 80 parts by weight of an average diameter of about 0.6 mm, 16.4 parts by weight of molten LDPE, 0.3 parts by weight of DCP crosslinking agent, 2 parts by weight of AC foaming agent, 0.5 parts by weight The pre-foamed blend material of zinc oxide in parts by weight, stearic acid in 0.5 parts by weight and 1010 antioxidant in 0.3 parts by weight is prepared by molding and foaming.

[0022] The grades or models of each material in the above-mentioned pre-foamed blended material are:

[0023] ABS (grade 0215A), Jilin Petrochemical. LDPE (grade 2102TN26), Qilu Petrochemical. Dicumyl peroxide (DCP), technical grade. AC foaming agent, model Dn8, Shanghai Wenhua Chemical Pigment Co., Ltd. Zinc oxide (ZnO), analytically pure, Sinopharm Chemical Reagent Co., Ltd. Antioxidant 1010, industrial grade. Stearic acid, analytically pure, Sinopharm Chemical Reagent Co., Ltd.

[0024] The preparation technol...

Embodiment 2

[0028] The modified ABS foaming material is made of ABS resin particles comprising 74 parts by weight of about 0.6mm in average diameter, 20 parts by weight of melting LDPE, DCP crosslinking agent of 0.5 parts by weight, AC blowing agent of 3 parts by weight, 1 The pre-foamed blended material of zinc oxide in parts by weight, stearic acid in 1 part by weight and 1010 antioxidant in 0.5 parts by weight is prepared by molding and foaming.

[0029] The grades or models of each material in the above-mentioned pre-foamed blended material are:

[0030] ABS (grade 0215A), Jilin Petrochemical. LDPE (grade 2102TN26), Qilu Petrochemical. Dicumyl peroxide (DCP), technical grade. AC foaming agent, model Dn8, Shanghai Wenhua Chemical Pigment Co., Ltd. Zinc oxide (ZnO), analytically pure, Sinopharm Chemical Reagent Co., Ltd. Antioxidant 1010, industrial grade. Stearic acid, analytically pure, Sinopharm Chemical Reagent Co., Ltd.

[0031] The preparation technology of modified ABS foam...

Embodiment 3

[0035] The modified ABS foaming material is made of ABS resin particles comprising 75 parts by weight with an average diameter of about 0.6 mm, 19.2 parts by weight of molten LDPE, DCP crosslinking agent of 0.3 parts by weight, AC foaming agent of 4 parts by weight, 0.5 parts by weight of The pre-foaming blended material of zinc oxide, 0.5 weight part of stearic acid and 0.5 weight part of 1010 antioxidant is prepared by molding and foaming.

[0036] The grades or models of each material in the above-mentioned pre-foamed blended material are:

[0037] ABS (grade 0215A), Jilin Petrochemical. LDPE (grade 2102TN26), Qilu Petrochemical. Dicumyl peroxide (DCP), technical grade. AC foaming agent, model Dn8, Shanghai Wenhua Chemical Pigment Co., Ltd. Zinc oxide (ZnO), analytically pure, Sinopharm Chemical Reagent Co., Ltd. Antioxidant 1010, industrial grade. Stearic acid, analytically pure, Sinopharm Chemical Reagent Co., Ltd.

[0038] The preparation technology of modified ABS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com