Brewing method capable of increasing fruit aroma of blueberry wine

A technology for blueberry wine and fruity aroma, applied in the field of food processing, can solve the problems affecting the overall quality of sensory evaluation, insufficient aroma of blueberry wine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

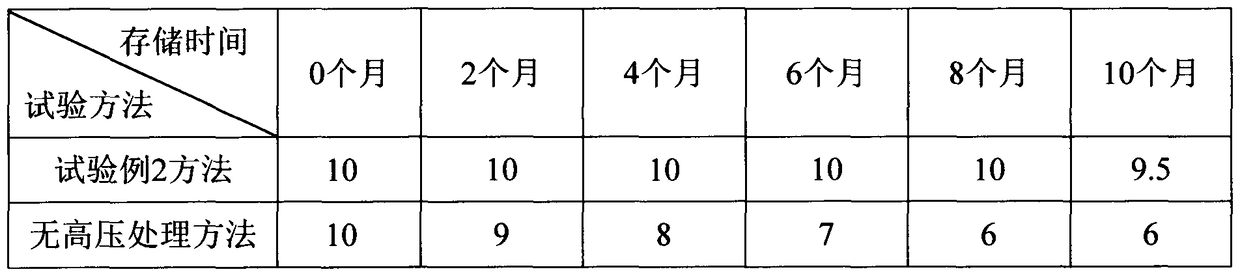

Examples

Embodiment 1

[0044] Select 10kg of fully mature blueberry fruit, remove rotten fruit, and remove fruit stems and impurities. After the blueberries were crushed and squeezed to obtain 9.1 L of fruit juice, 728 mg of sulfur dioxide was added immediately and stirred evenly, and then 455 mg of compound enzyme was added and stirred evenly (wherein 91 mg of cellulase, 91 mg of pectin lyase, 91 mg of polygalacturonase, pectin acyl Hydrolase 45.5mg, β-D-glucosidase 682.5mg, α-L-arabinosidase 455mg, α-L-rhamnosidase 227.5mg) (Shanghai Jietu Industry and Trade Co., Ltd., Beijing Suolaibao Technology Co., Ltd. company), enzymatically hydrolyzed at 25°C for 4h to obtain blueberry broken liquid. Add 455g of sucrose to the crushed blueberry liquid and stir evenly, add 4.55g of Saccharomyces cerevisiae BDX (Shanghai Jietu Industry and Trade Co., Ltd.) and stir evenly, then ferment at 10°C, and turn the tank every 4 days, and the sugar content will be less than 4g after 40 days / L, to stop the fermentati...

Embodiment 2

[0066] Select 50kg of fully mature blueberry fruit, remove rotten fruit, and remove fruit stems and impurities. After crushing the blueberries and squeezing the juice to obtain 45.5L of fruit juice, immediately add 4550mg of sulfur dioxide and stir evenly, then add 1820mg of compound enzyme and stir evenly (wherein cellulase 273mg, pectin lyase 546mg, polygalacturonase 273mg, pectin acyl Hydrolase 91mg, β-D-glucosidase 364mg, α-L-arabinosidase 91mg, α-L-rhamnosidase 182mg) (Shanghai Jietu Industry and Trade Co., Ltd., Beijing Soleibao Technology Co., Ltd.), Enzymolysis was carried out at 30° C. for 3 hours to obtain broken blueberry liquid. Add 2730g of sucrose to the crushed blueberry liquid and stir evenly, add 18.2g of Saccharomyces cerevisiae BDX (Shanghai Jietu Industry and Trade Co., Ltd.) and stir evenly, then ferment at 15°C, and turn the tank every 5 days, and the sugar content will be less than 4g after 35 days / L, stop the fermentation, diatomaceous earth filter an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com