A method of recovering metal aluminum from aluminum ash

A technology for metal aluminum and aluminum ash, applied in the field of aluminum ash recycling, can solve the problems of high aluminum loss rate, high energy consumption of extraction methods, and more molten aluminum entrained in slag, so as to solve the loss of over-grinding, improve the purity, and improve the The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

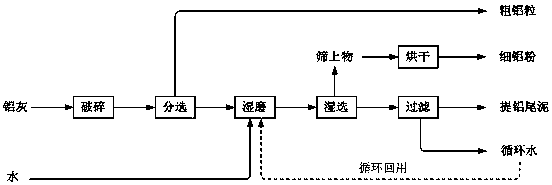

[0032] The method for recovering metal aluminum from aluminum ash may further comprise the steps:

[0033] The aluminum ash waste from a certain place in Gongyi is fully crushed by a hammer crusher, and the crushed products are screened by a linear vibrating screen with a screen aperture of 10mm. The purity of the large aluminum particles on the screen can reach more than 95%. The product under the sieve is transported to the ball mill through the belt, and water is added according to the ratio of solid to liquid during the ball milling process. After solid-liquid separation and drying treatment, fine aluminum powder is obtained. The purity of fine aluminum powder reaches more than 70%. The slurry under wet sieve is subjected to pressure filtration treatment to obtain aluminum extraction tailings and filtrate. The filtrate is recycled and used as ball milling process and Addition of water during wet sieving. Compared with the traditional dry separation process, the "wet grind...

Embodiment 2

[0035] The method for recovering metal aluminum from aluminum ash may further comprise the steps:

[0036] The aluminum ash waste from a certain place in Luoyang is fully crushed by a roller crusher, and the crushed product is screened by a linear vibrating screen with a screen aperture of 5mm. The purity of the large aluminum particles on the screen can reach more than 90%. The under-screen product is transported to the ball mill through a belt. During the ball milling process, water is added according to the ratio of solid to liquid ratio of 1:0.8. After the ball milling, the slurry is separated by wet sieving through a linear vibrating screen with a screen aperture of 150 mesh. The solids on the wet sieve are passed through After solid-liquid separation and drying treatment, fine aluminum powder is obtained. The purity of fine aluminum powder reaches more than 60%. The slurry under the wet sieve is subjected to pressure filtration treatment to obtain aluminum extraction tail...

Embodiment 3

[0038] The method for recovering metal aluminum from aluminum ash may further comprise the steps:

[0039] The aluminum ash waste from a certain place in Dengfeng is fully crushed by an impact crusher, and the crushed product is screened by a linear vibrating screen with a screen aperture of 10mm. The purity of the large aluminum particles on the screen can reach more than 95%. The under-screen product is transported to the ball mill through a belt. During the ball milling process, water is added according to the ratio of solid-liquid ratio of 1:1. After the ball milling, the slurry is separated by wet sieving through a linear vibrating screen with a screen aperture of 100 mesh. The solids on the wet sieve are passed through After solid-liquid separation and drying treatment, fine aluminum powder is obtained. The purity of fine aluminum powder reaches more than 65%. The slurry under the wet sieve is subjected to pressure filtration treatment to obtain aluminum extraction tailin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com