Flame-retardant antibacterial environment-friendly PVC artificial leather

A kind of artificial leather, environmental protection technology, applied in the direction of textile and paper making, application, furniture parts, etc., to achieve the effect of improving smoke density, improving smoothness and density, and solving environmental protection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

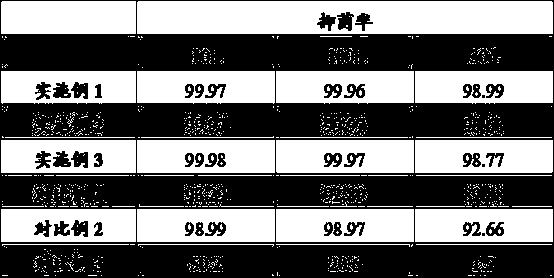

Examples

Embodiment 1

[0029] S1. Select the release paper and the base fabric, and the fabric is preheated, and a layer of polyurethane adhesive is coated on the outer layer of the base fabric to form an adhesive layer;

[0030] S2. Coating an intermediate layer on the adhesive layer, the intermediate layer is a smoke suppressing flame retardant, the smoke suppressing flame retardant is composed of iron red, aluminum hydroxide, zinc borate, iron red, aluminum hydroxide , the parts by weight of zinc borate are respectively: 20%, 35%, 45%;

[0031] S3, preparation of polyvinyl chloride foaming slurry: according to the following formula quantity: 100 parts of PVC resin powder, 40 parts of dioctyl phthalate, SiO 2 5 parts, 0.3 parts of sodium stearate, 1 part of foam stabilizer, 2 parts of foaming agent, 1 part of polyhexamethylene biguanide, 15 parts of propylene glycol adipate, added to the high-speed disperser for stirring, stirring During the process, air is introduced into the slurry from the bo...

Embodiment 2

[0035] S1. Select the release paper and the base fabric, and the fabric is preheated, and a layer of polyurethane adhesive is coated on the outer layer of the base fabric to form an adhesive layer;

[0036] S2. Coating an intermediate layer on the adhesive layer, the intermediate layer is a smoke suppressing flame retardant, the smoke suppressing flame retardant is composed of iron red, aluminum hydroxide, zinc borate, iron red, aluminum hydroxide , the parts by weight of zinc borate are respectively: 20%, 40%, 40%;

[0037] S3, preparation of polyvinyl chloride foaming slurry: according to the following formula quantity: 100 parts of PVC resin powder, 40 parts of dioctyl phthalate, SiO 2 10 parts, 1.5 parts of sodium stearate, 0.5 parts of foam stabilizer, 3 parts of foaming agent, 1 part of polyhexamethylene biguanide, 16 parts of propylene glycol adipate, added to the high-speed disperser for stirring, stirring During the process, air is introduced into the slurry from the ...

Embodiment 3

[0041] S1. Select the release paper and the base fabric, and the fabric is preheated, and a layer of polyurethane adhesive is coated on the outer layer of the base fabric to form an adhesive layer;

[0042] S2. Coating an intermediate layer on the adhesive layer, the intermediate layer is a smoke suppressing flame retardant, the smoke suppressing flame retardant is composed of iron red, aluminum hydroxide, zinc borate, iron red, aluminum hydroxide , the parts by weight of zinc borate are respectively: 35%, 35%, 30%;

[0043] S3, preparation of polyvinyl chloride foaming slurry: according to the following formula quantity: 100 parts of PVC resin powder, 40 parts of dioctyl phthalate, SiO 2 6 parts, 1.5 parts of sodium stearate, 1.2 parts of foam stabilizer, 2.2 parts of foaming agent, 2.1 parts of polyhexamethylene biguanide, 10.6 parts of propylene glycol adipate, added to the high-speed disperser for stirring, stirring In the process, air is introduced into the slurry from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com